- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 09, 2024 03:09 Back to list

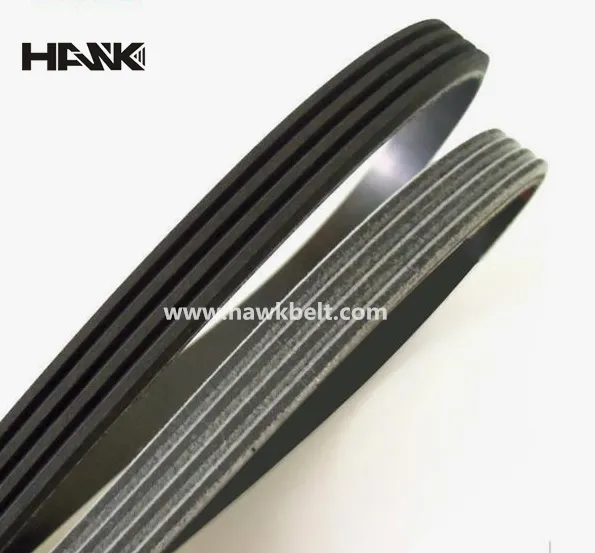

Understanding the Function and Applications of Power Transmission Belts in Machinery

Understanding Power Transmission Belts

Power transmission belts play a crucial role in various mechanical systems, serving as a vital component for conveying power from one part of a machine to another. This technical solution is essential in a multitude of applications, including automotive, industrial machinery, and household appliances. In this article, we will explore the types, functions, and applications of power transmission belts.

What Is a Power Transmission Belt?

At its core, a power transmission belt is a looped flexible material designed to transfer energy between pulleys. Typically made from rubber, fabric, or a combination thereof, these belts can efficiently transmit power while minimizing energy loss due to friction.

Types of Power Transmission Belts

The most common types of power transmission belts include

1. V-Belts V-belts feature a trapezoidal cross-section that fits into the grooves of V-shaped pulleys, ensuring a firm grip and reducing slippage. These belts are popular in automotive applications and machinery because they can handle substantial loads and operate quietly.

2. Flat Belts With a rectangular cross-section, flat belts can be used in applications requiring long runs between pulleys. They are versatile and are often found in conveyor systems and industrial machinery.

3. Timing Belts Also known as synchronous belts, timing belts have teeth that mesh with pulleys to maintain precise timing between rotating components. Commonly used in engines and robotics, they ensure that movements remain synchronized.

4. Round Belts These belts are circular in cross-section and often used in light-duty applications. Round belts can be particularly useful in conveyor systems where flexibility is required.

transmission belt\/power transmission belt

Functions of Power Transmission Belts

Power transmission belts serve several key functions

- Energy Transfer The primary function of a power transmission belt is to transfer energy from one component to another, enabling machines and vehicles to operate effectively.

- Tensioning and Alignment Belts help maintain proper alignment between pulleys, minimizing wear and tear that could lead to system failure.

- Absorbing Shock Loads Power transmission belts can absorb shocks and vibrations, ensuring smoother operation and extending the life of machinery.

Applications

The applications of power transmission belts are vast and varied. In the automotive industry, for example, timing belts synchronize the rotation of the crankshaft and camshaft, ensuring proper engine function. V-belts are commonly used to drive accessories like alternators and water pumps.

In industrial settings, flat belts are often found in conveyor systems, facilitating the transport of materials across different production stages. Even in household appliances, such as washing machines and dryers, power transmission belts are indispensable for ensuring smooth operation.

Conclusion

Power transmission belts are an essential component in the world of machinery and automotive applications. Their ability to efficiently transmit power while absorbing shocks and minimizing wear makes them an integral part of numerous systems. As technology continues to evolve, so too will the design and application of power transmission belts, paving the way for even more efficient and durable solutions in the future. Understanding the various types and their applications can enhance the effectiveness of machines and ensure longevity, making them a topic well worth studying.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025