- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 18, 2024 11:51 Back to list

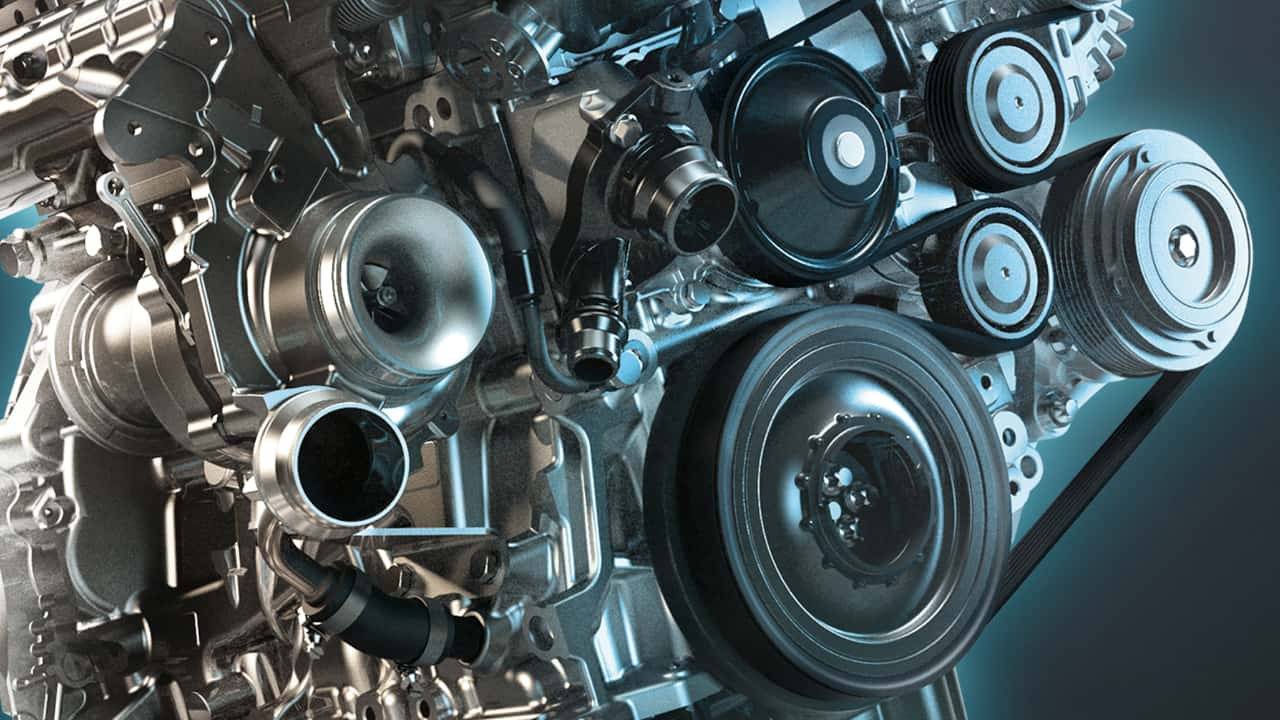

PK Belts for Japanese Cars and Automotive Applications

Understanding Auto PK Belts for Japanese Cars

When it comes to automotive components, the significance of belts cannot be overstated, particularly in Japanese cars, which are known for their durability and efficiency. Among these components, the PK belt stands out due to its unique design and efficient performance. This article will explore what PK belts are, their applications in Japanese cars, and why they are essential for optimal vehicle functionality.

What is a PK Belt?

A PK belt, also known as a poly v-belt, is a type of serpentine belt characterized by its flat design and multiple grooves. This unique structure allows it to transmit power efficiently across several accessories, including the alternator, power steering pump, air conditioning compressor, and water pump. The PK belt is constructed from high-quality materials to withstand the various stresses and strains present in automotive operations, ensuring a long service life.

Applications in Japanese Cars

Japanese car manufacturers, such as Honda, Toyota, Nissan, and Subaru, commonly utilize PK belts in their models. These belts are engineered to meet the specific power demands of the vehicle's engine, optimizing performance while minimizing energy loss. For instance, in compact models like the Honda Civic, the PK belt plays a critical role in ensuring that all auxiliary systems operate smoothly, which is essential for maintaining fuel efficiency and overall vehicle performance.

pk belt for japanese car\/auto pk belt

The PK belt's ability to handle higher loads with a smaller width gives it an advantage over traditional v-belts. This is particularly advantageous in the compact designs prevalent in many Japanese cars, where space is at a premium. The PK belt's flexibility also allows for easier installation and replacement, further enhancing the serviceability of the vehicle.

Importance of PK Belts

The functionality of the PK belt is vital for the smooth operation of various vehicle systems. A worn or damaged PK belt can lead to several issues, including decreased performance of accessories, increased fuel consumption, and, in some cases, engine overheating. Regular inspection and maintenance of the PK belt are essential to prevent costly repairs down the line.

Drivers should be aware of the signs indicating that a PK belt may need replacement. These can include squeaking noises when the engine is running, visible fraying or cracks on the belt surface, or difficulty in steering due to power steering failure. Proactive measures, such as timely replacement and routine checks, can greatly enhance vehicle longevity and reliability.

Conclusion

In conclusion, the PK belt is a critical component in the operation of numerous Japanese cars. Its design allows for efficient power transmission across various systems, making it an indispensable part of vehicle maintenance. By understanding the function and importance of PK belts, car owners can take proactive steps to ensure their vehicles remain in optimal condition. Ultimately, investing in high-quality PK belts and adhering to regular maintenance schedules will contribute to a smoother, more efficient driving experience in Japanese automobiles.

-

Serpentine Belt Use: Reliable Car Belt Replacement and Sizing Solutions

NewsJul.28,2025

-

High Performance Variable Belt Drive for Precise Timing Control

NewsJul.27,2025

-

Buy Serpentine Belt Online – Affordable Prices & Durable Quality

NewsJul.26,2025

-

High-Performance Metric Variable Speed Belts for Industrial Use

NewsJul.25,2025

-

High-Quality Endless Flat Drive Belt for Precision Power Transmission

NewsJul.24,2025

-

High-Performance Serpentine Belt for Car Engines – Durable & Reliable

NewsJul.23,2025