- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 26, 2024 23:45 Back to list

Understanding V-Belt Pricing and Cost Factors for Efficient Budgeting

Understanding the Cost of V-Belts An In-Depth Analysis

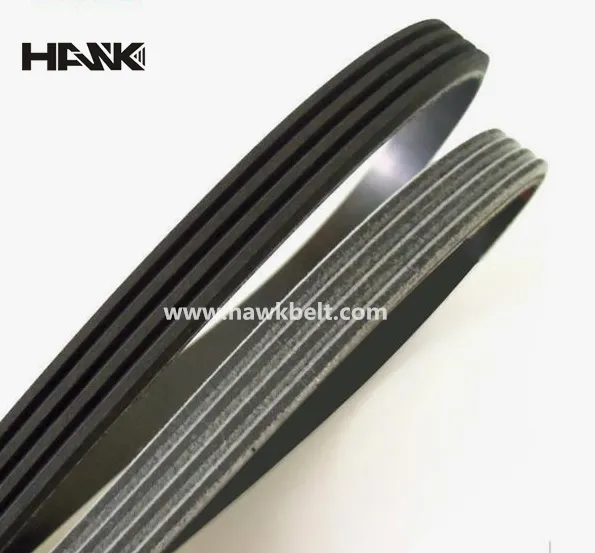

V-belts, crucial components in various mechanical systems, play a significant role in power transmission across multiple industries. They are widely used in applications ranging from automotive engines to industrial machinery. As businesses, engineers, and technicians seek to maintain and optimize their equipment, understanding the cost components of V-belts becomes essential. This article delves into the factors affecting V-belt costs, types of V-belts, and ways to manage expenses effectively.

Factors Influencing V-Belt Costs

1. Material Composition V-belts are typically made from rubber, polyester, or polyurethane, with each material offering different durability levels and performance characteristics. Higher quality materials tend to cost more, but they often provide better longevity and efficiency, potentially reducing replacement frequency.

2. Belt Size and Length The size and length of a V-belt directly impact its cost. Longer belts typically require more material and are therefore more expensive. Additionally, specific sizes may be designed for unique machinery, which can increase production costs due to lower economies of scale.

3. Belt Type There are several types of V-belts, including classical V-belts, narrow V-belts, and variable speed belts. Each type has its own specifications, and the cost can vary significantly. For instance, variable speed belts, designed to operate efficiently under varying loads, may incur higher manufacturing costs due to their complex design.

4. Brand and Manufacturer Different manufacturers offer V-belts with varying price points, influenced by brand reputation and market position. Well-known brands often command higher prices due to perceived reliability and quality. However, it’s vital to evaluate whether the higher cost correlates with superior performance or durability.

5. Volume Purchase Discounts Businesses that purchase V-belts in bulk often enjoy discounts. This is particularly beneficial for companies that rely heavily on V-belts for operational purposes, as it reduces the per-unit cost significantly.

v belt cost

The Role of V-Belt Configuration

The configuration of a V-belt system can greatly affect its overall cost. This includes the number of belts required for a particular application, the arrangement of pulleys, and any additional components. Designing a system with the optimal number of belts can minimize costs while maximizing efficiency. It’s essential to analyze system requirements carefully, as both over-specification and under-specification can lead to unnecessary expenses.

Maintenance and Lifespan

Another key factor in the overall cost of V-belts is maintenance. Regular inspections and timely replacements are crucial in preventing more significant failures that could lead to expensive repairs. Implementing a proactive maintenance program can extend a belt’s operational lifespan, ultimately providing better return on investment. Such measures often involve monitoring alignment, tension, and signs of wear and tear.

Choosing the Right V-Belt

When selecting V-belts, it’s essential to strike a balance between cost and quality. While it may be tempting to choose the cheapest option, it’s important to consider factors such as longevity and compatibility with the machinery. Investing in high-quality V-belts can reduce long-term costs associated with frequent replacements and decreased efficiency.

Conclusion

Understanding the costs associated with V-belts is vital for businesses and industries that rely on effective power transmission. Factors such as material type, size, brand, and maintenance requirements all influence the overall cost of V-belts. By selecting the right type of belt and implementing sound maintenance practices, companies can optimize their operational efficiency and lower their long-term expenses. Ultimately, making informed decisions regarding V-belt procurement can lead to significant savings and enhanced performance in mechanical systems, allowing businesses to focus on growth and productivity.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025