- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 08, 2024 06:00 Back to list

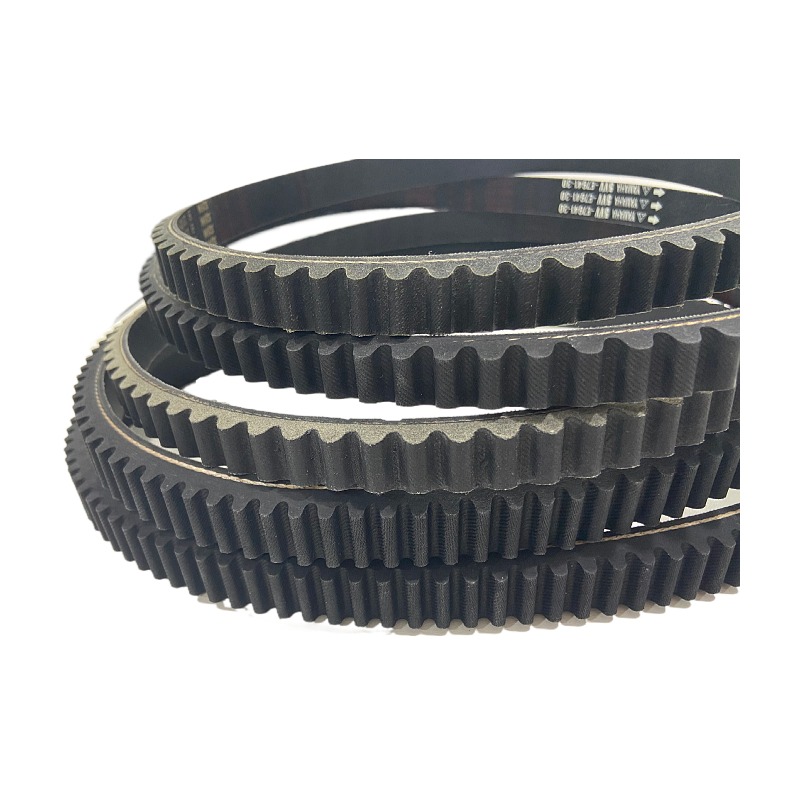

Ribbed V-Shaped Conveyor Belt for Enhanced Handling Efficiency and Performance

Ribbed vs. V Conveyor Belts A Comprehensive Overview

Conveyor belts are an integral part of modern industrial processes, playing a crucial role in the efficient transport of goods and materials across manufacturing, packaging, and distribution facilities. Among the various types of conveyor belts available, ribbed and V-shaped conveyor belts are two popular options, each designed to meet specific operational needs. This article provides a comprehensive overview of ribbed and V conveyor belts, highlighting their features, advantages, and applications.

Understanding Ribbed Conveyor Belts

Ribbed conveyor belts, characterized by their raised surfaces or ridges, are engineered to provide enhanced grip and stability for transported materials. The ribbed structure facilitates better traction, minimizing the risk of slippage during operation. These belts are often manufactured from durable materials, such as rubber or polyurethane, ensuring long-lasting performance even under heavy loading conditions.

Key Features of Ribbed Conveyor Belts

1. Enhanced Grip The ribbed design allows for improved contact with the conveyed items, reducing the chances of slipping, especially when transporting loose or bulk materials. 2. Versatility Ribbed conveyor belts come in various widths and rib heights, making them suitable for different applications, including incline and decline operations.

3. Minimized Product Damage The raised ribs create a cushioning effect, protecting delicate items from damage during transport.

4. Efficient Transport The unique design aids in the efficient movement of products, allowing for faster cycle times in production processes.

Exploring V Conveyor Belts

V-shaped conveyor belts, on the other hand, feature a distinct V cross-section that allows for the efficient handling of materials. These belts are particularly effective in transporting bulk materials and are commonly used in various industries, including agriculture, mining, and food processing.

Key Features of V Conveyor Belts

1. Self-Centring Design The V shape helps keep materials in the center of the belt, preventing spillage and ensuring smooth transport, especially on inclines.

ribbed v conveyor belt

2. Optimized for Bulk Handling V conveyor belts can handle larger volumes of products, making them ideal for applications where high throughput is required.

3. Exceptional Stability The unique design provides better stability during operation, accommodating shifts in weight distribution without compromising performance.

4. Adaptable to Various Systems V conveyor belts can be integrated into different conveyor systems and can be customized to meet specific operational requirements.

Comparison of Ribbed and V Conveyor Belts

When deciding between ribbed and V conveyor belts, several factors come into play, including the type of materials being transported, the incline or decline of the conveyor, and the specific operational environment. Here’s a brief comparison of the two

1. Traction and Grip Ribbed belts are generally superior in providing traction for lighter or more delicate materials, while V belts excel in stability and support for bulkier loads.

2. Use Cases Ribbed conveyor belts are preferred for applications requiring careful handling of products, such as packaging operations or assembly lines. Conversely, V conveyor belts are often chosen for heavy-duty applications, such as mining and bulk handling.

3. Incline Transport Both belt types can operate on inclines, but ribbed belts tend to perform better on steeper angles due to their grip, whereas V belts are designed for more constant slopes.

Conclusion

In conclusion, both ribbed and V conveyor belts serve distinct purposes within conveyor systems. The choice between the two largely depends on the specific operational requirements and the types of materials being handled. Ribbed conveyor belts provide excellent grip for lighter products, while V conveyor belts excel in handling bulk materials efficiently. Understanding the features and benefits of each type can lead to more informed decisions, ultimately enhancing productivity and operational efficiency in various industrial settings.

By selecting the right conveyor belt type for the intended application, businesses can ensure a smoother workflow and reduce the risk of material loss or damage, paving the way for more streamlined operations.

-

High-Quality Endless Flat Drive Belt for Precision Power Transmission

NewsJul.24,2025

-

High-Performance Serpentine Belt for Car Engines – Durable & Reliable

NewsJul.23,2025

-

High Efficiency V Belt Drive with Double & Toothed Options for Industry

NewsJul.22,2025

-

Affordable Fan Belt Cost - Compare Prices & Save | Auto Parts Deals

NewsJul.22,2025

-

China Factory 6PK1130 EPDM Rubber Engine Conveyor Belt Supplier

NewsJul.21,2025

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025