- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Th8 . 30, 2024 01:19 Back to list

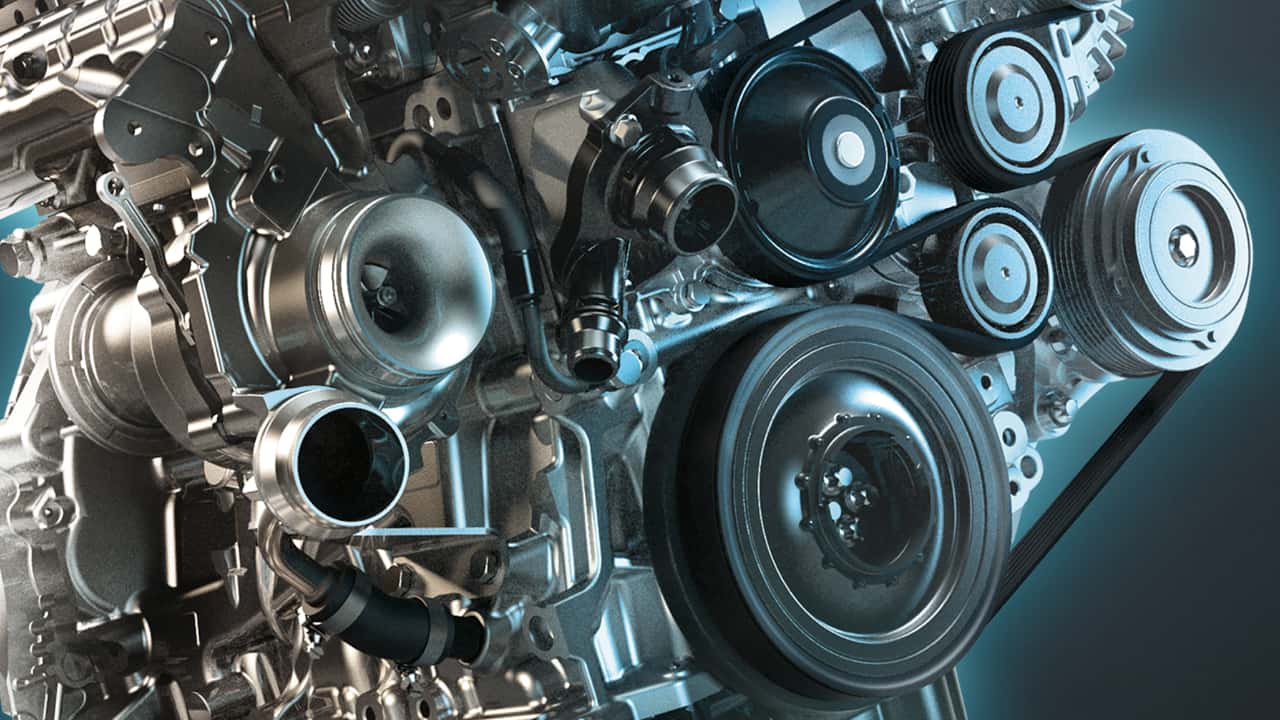

High-Quality Flat Leather Machine Belts | Durable & Reliable Solutions

The Importance of Flat Leather Machine Belts in Industrial Applications

Flat leather machine belts have been an essential component in various industrial applications for many years. Their unique properties, such as flexibility, durability, and the ability to withstand high tension, make them ideal for transmitting power and motion in machinery. This article explores the significance of flat leather machine belts, their manufacturing process, and their applications across different industries.

Historical Background

The use of leather belts in machinery can be traced back to the early days of the Industrial Revolution. Before the advent of modern synthetic materials, leather was one of the few materials available that could handle the mechanical demands of various machines. The development of flat leather belts allowed for improved power transmission, facilitating the operation of everything from textile looms to sawmills. Over the decades, advancements in leather processing have enhanced the quality and performance of these belts, ensuring their continued relevance in contemporary industrial settings.

Manufacturing Process

The production of flat leather machine belts involves several key steps. First, high-quality hides are sourced, often from cattle, due to their strength and durability. The hides undergo tanning, which enhances their resistance to water and wear, ensuring longevity in industrial applications. After tanning, the leather is cut into strips of uniform width and thickness, appropriate for specific machinery needs.

flat leather machine belts

These belts are typically reinforced with different materials, such as cotton or polyester, to enhance their load-bearing capacity and flexibility. Once the strips are prepared, they are often glued or stitched together to create continuous loops, depending on the design requirements of the application. The final product undergoes rigorous quality control checks to meet industry standards before being dispatched for use in various machines.

Applications

Flat leather machine belts are widely used across various sectors, including manufacturing, agriculture, and transportation. In manufacturing, they are integral to power transmission systems, linking motors to gears and pulleys. In agriculture, these belts are commonly found in machinery such as grain elevators and threshers, where they facilitate efficient operations.

Moreover, leather belts are valued for their ability to absorb shock and dampen vibrations, making them suitable for high-speed machinery. Their resistance to heat and chemicals further enhances their appeal, particularly in environments where synthetic belts might degrade rapidly.

Conclusion

Flat leather machine belts remain a critical element in the industrial landscape, combining traditional craftsmanship with modern engineering requirements. Their durability and reliability ensure that they continue to perform effectively across various applications, even in an era dominated by synthetic materials. While technological advancements may lead to the development of new materials, the unique properties of leather still hold a crucial place in many industrial processes. As industries evolve, the significance of flat leather machine belts is likely to endure, embodying a blend of history and innovation that has defined industrial progress for centuries.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025