- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Th9 . 28, 2024 23:54 Back to list

Understanding the Function and Maintenance of Serpentine Belts in Alternators

Understanding the Alternator and Serpentine Belt A Comprehensive Guide

The alternator and serpentine belt play crucial roles in the functioning of a vehicle's electrical system and overall performance. Understanding how these components work together can help vehicle owners maintain their cars effectively and avoid potential issues. This article will explore the purpose of the alternator, the function of the serpentine belt, and their interrelationship.

What is an Alternator?

An alternator is an essential component of a vehicle's electrical system, responsible for converting mechanical energy into electrical energy. It generates electricity to power the vehicle's electrical systems, such as the headlights, radio, and air conditioning, while also recharging the car's battery. The alternator contains several key parts, including the rotor, stator, and voltage regulator.

The rotor spins inside the stator, creating an electromagnetic field that generates alternating current (AC). The voltage regulator then converts this AC into direct current (DC), which is what car batteries and electrical systems need to function. A properly functioning alternator is crucial for the longevity of both the battery and the vehicle's electrical components.

What is a Serpentine Belt?

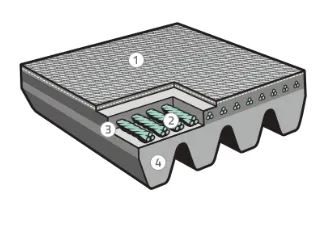

A serpentine belt, also known as a multi-ribbed belt or serpentine drive belt, is a single, continuous belt that powers multiple peripheral devices in an internal combustion engine. These devices typically include the alternator, power steering pump, water pump, air conditioning compressor, and sometimes even the crankshaft. The design of the serpentine belt allows it to effectively transfer power from the engine to these components, ensuring they operate smoothly and efficiently.

Serpentine belts are typically made from reinforced rubber, which provides the necessary flexibility and strength to handle the various loads and conditions within the engine compartment. Unlike older systems that used multiple belts for different components, the serpentine belt system simplifies the layout, reduces engine space, and is generally easier to maintain.

The Interrelationship Between the Alternator and Serpentine Belt

alternator serpentine belt

The alternator and serpentine belt are intricately linked; the serpentine belt physically connects the engine to the alternator. When the engine turns, it rotates the serpentine belt, which in turn spins the alternator. This process generates the electricity needed to power the vehicle's electrical systems.

If the serpentine belt stretches, wears out, or breaks, it can lead to serious issues. Without proper tension, the belt may slip, leading to inadequate power being delivered to the alternator. This can result in diminished electrical output, which may leave the car's battery unable to recharge and lead to failure of electrical components. In extreme cases, a broken serpentine belt can cause the alternator to stop working entirely, leaving the driver without power and potentially stranded.

Signs of Alternator or Serpentine Belt Issues

Several signs can indicate that something is wrong with either the alternator or serpentine belt. Common symptoms of a failing alternator include dimming headlights, electrical issues with the dashboard, or unusual noises such as grinding or whining. If you notice any of these signs, it is essential to have the alternator inspected by a professional mechanic.

For the serpentine belt, look out for signs of wear such as cracks, fraying, or glazing on the belt surface. A slipping or squeaking noise when starting the engine can also indicate that the serpentine belt is loose or damaged. Regular inspections can help catch these issues early and ensure the longevity of both the alternator and serpentine belt.

Maintenance Tips

To maintain the performance of the alternator and serpentine belt, it's vital to follow some basic maintenance tips. Regularly check your vehicle's belt for signs of wear and replace it according to the manufacturer’s recommendations, typically every 50,000 to 100,000 miles. Additionally, ensure that the alternator is functioning correctly by keeping an eye on the battery’s performance and having the electrical system checked during routine maintenance.

In conclusion, the alternator and serpentine belt are vital components that work together to ensure your vehicle runs smoothly. Being aware of their functions and how to identify potential problems can save you time and money in repairs and enhance your safety on the road. Regular maintenance checks can go a long way in prolonging the life of your vehicle's electrical system.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025