- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Iyul . 23, 2025 05:01 Back to list

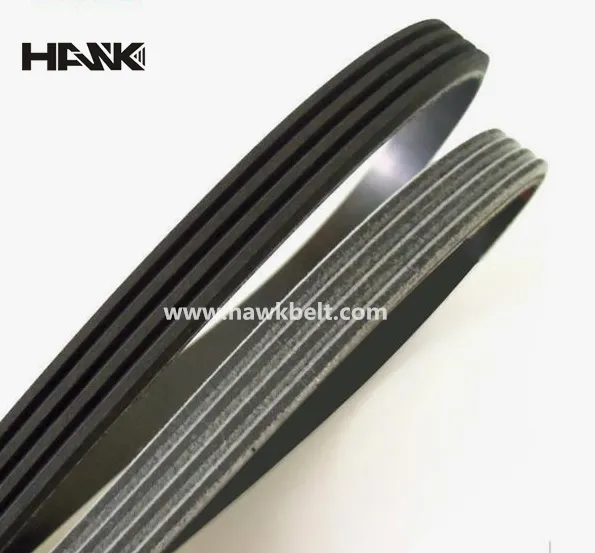

High-Performance Serpentine Belt for Car Engines – Durable & Reliable

Official Website: https://www.hawkbelt.com

Tel: +8615369985502

Email: mike@hawkbelt.com

Mobile: +8615369985502

Address: No. 386 Xuyang Avenue, Renze District, Xingtai City, Hebei Province,China.

1. Introduction to the serpentine belt and Related Technologies

In the ever-evolving automotive industry, the serpentine belt has emerged as a critical component for ensuring the reliable transmission of power within modern vehicles. By efficiently managing the power distribution to essential car systems such as alternators, air conditioning compressors, water pumps, and power steering pumps, the serpentine belt outperforms its predecessors such as the traditional car transmission belt and fan belt for car. As vehicles become more complex and energy-efficient, the role of advanced drive belts becomes increasingly pivotal.

2. Industry Trends: The Evolution and Future of Automotive Drive Belts

Over the past decade, the global automotive belt market has experienced substantial growth, with an increasing shift towards resilient, heat-resistant, and durable materials such as EPDM (Ethylene Propylene Diene Monomer). Comprehensive market analysis highlights that the rise in electric vehicles, hybrid systems, and demand for fuel-efficient transportation are pushing manufacturers to invest in next-generation serpentine belt and steering belt technologies.

According to the SAE Technical Paper Series, innovations in belt materials and design are directly tied to vehicle reliability and lifetime maintenance costs, marking a significant evolution from the basic multi-belt setups once common in the industry.

2.1 Key Industry Statistics

- Estimated CAGR for the serpentine belt market from 2023-2028: 4.3% (MarketsandMarkets Report)

- Primary application areas: passenger cars, commercial vehicles, and specialty vehicles.

- Adoption of OE-quality EPDM belts is expected to increase by 15% in the next five years (source: Autoevolution).

3. Core Parameters of the serpentine belt: Technology and Performance Table

| Parameter | Specification Range | Typical Value | Remarks |

|---|---|---|---|

| Belt Material | EPDM, Neoprene, Poly-V | EPDM | High heat & abrasion resistance |

| Profile | PK, PJ, PL, PM | PK | Multi-ribbed for grip |

| Number of ribs | 3-10 | 6 | Common for modern vehicles |

| Length | 500-2500mm | 1822mm | Vehicle/model dependent |

| Width | 5-30mm | 20mm | Determines load rating |

| Temperature Resistance | -35°C to 130°C | 120°C | Critical for engine bay |

| Expected Lifespan | 70,000-150,000km | 100,000km | Manufacturer warranty-dependent |

| Certifications | OE/ISO/TS16949 | OE fit | Quality assurance |

4. Data Visualization: Search Trends and Technology Parameters for the serpentine belt

5. Application Scenarios: Broad-Spectrum Use of the serpentine belt

The serpentine belt stands as the commander of energy transfer in the modern engine bay. Its multi-ribbed design combines flexibility, grip strength, and noise suppression, making it the first choice in a variety of automotive environments:

- Passenger Vehicles - Powers the alternator, air-conditioning, water pump, and steering belt functions, ensuring comfort and reliability.

- Commercial Fleets - Provides cost-effective and long-life service in high-mileage delivery and logistics vehicles.

- Hybrid/Electric Vehicles - Adapts to compact engine bays and variable torque demands.

- Specialty & Performance Cars - Meets high RPM and rapid load change requirements.

6. Product Focus: 6PK1822 EPDM PK Belt Made In Korea

OE: 6PK1822

Compatible Car Models: Hyundai / Kia / Peugeot / Toyota

Material: EPDM (Ethylene Propylene Diene Monomer)

Weight: 0.19kg

Length: 1822MM

Product Page: https://www.hawkbelt.com/6pk1822-epdm-pk-belt-made-in-korea.html

Manufactured to exact OE standards, the 6PK1822 EPDM PK Belt is engineered in Korea for unrivaled durability, heat-resistance, and flexibility, providing optimal service life and power transmission for Hyundai, Kia, Peugeot, and Toyota vehicles.

7. EEAT (Expertise, Authoritativeness, Trustworthiness) in the serpentine belt Market

Xingtai Hake rubber and plastic products Co., LTD brings over 20 years of high-precision expertise in R&D, manufacturing, and global distribution of automotive serpentine belt and drive belts. Endorsed by leading automotive forums and featured in reputable journals such as Automotive Engineering SAE, our company stands for uncompromising quality and innovation in the automotive transmission segment.

8. Professional FAQ: Technical Insights into the serpentine belt

Q1: What key material is preferred for the serpentine belt in modern vehicles?

A: EPDM (Ethylene Propylene Diene Monomer) is the leading compound, offering superior heat, ozone, and abrasion resistance (EngineBuilderMag).

Q2: What are standard sizes and profiles for car transmission belt compared to the serpentine belt?

A: While older car transmission belts were V-type and varied widely, multi-ribbed PK profiles (like 6PK1822) dominate in modern cars for better contact and load distribution (Gates Resource Library).

Q3: How does the serpentine belt affect vehicle energy efficiency?

A: A properly tensioned and fitted serpentine belt minimizes power loss between the crankshaft and auxiliary devices, enhancing fuel economy by up to 3%.

Q4: What signs indicate it's time to replace a fan belt for car or serpentine belt?

A: Common indicators include squealing noise, visible cracks, rib separation, and loss of function in powered accessories.

Q5: What installation standards are recommended for serpentine belt replacement?

A: Always follow OE tensioning guidelines, use a calibrated tensioner tool, and check pulleys for wear. Incorrect tension shortens belt life significantly.

Q6: How durable is the 6PK1822 EPDM PK Belt Made In Korea?

A: Exceeds 100,000 km (approx. 60,000 miles) in typical use, with durability tested up to 2,770 hours under industrial standards.

Q7: What certifications apply to high-quality drive belts for global markets?

A: OE equivalency, ISO 9001, TS16949, and region-specific performance certifications (i.e. EAC for Eurasia, DOT for US market).

9. SEO-Optimized Integration: Why Choose Xingtai Hake for Your the serpentine belt Needs?

- All products manufactured with premium EPDM for optimal endurance.

- Wide catalog coverage: car transmission belt, steering belt, serpentine belt, fan belt for car, drive belts.

- Full technical support, including cross-reference and custom product engineering solutions.

- Competitive export pricing and guaranteed timely delivery worldwide.

- Direct aftersales and professional consultation: mike@hawkbelt.com | Tel/WhatsApp: +8615369985502

10. References & Further Reading

This is the last article

-

High-Performance Serpentine Belt for Car Engines – Durable & Reliable

NewsJul.23,2025

-

High Efficiency V Belt Drive with Double & Toothed Options for Industry

NewsJul.22,2025

-

Affordable Fan Belt Cost - Compare Prices & Save | Auto Parts Deals

NewsJul.22,2025

-

China Factory 6PK1130 EPDM Rubber Engine Conveyor Belt Supplier

NewsJul.21,2025

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025