- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

دسمبر . 05, 2024 15:57 Back to list

Exploring Synchroflex Timing Pulleys for Enhanced Mechanical Performance and Efficiency

Understanding Synchroflex Timing Pulleys An Essential Component in Mechanical Systems

Introduction

In the realm of mechanical engineering, timing pulleys are crucial components that facilitate the transfer of motion and power within various machinery and systems. Among the various types of timing pulleys available, Synchroflex timing pulleys have garnered attention for their efficiency and reliability. This article explores the characteristics, advantages, applications, and best practices associated with Synchroflex timing pulleys.

What are Synchroflex Timing Pulleys?

Synchroflex timing pulleys are specialized mechanical components designed to work seamlessly with timing belts. They are engineered to maintain synchronization between different parts of a machine, ensuring that motion is transmitted accurately and efficiently. The key feature of Synchroflex pulleys is their tooth profile, which is precisely designed to mesh with corresponding teeth on a timing belt. This tooth engagement reduces slippage and allows for consistent motion transmission, making them ideal for applications requiring high precision.

Key Characteristics

1. Material Quality Synchroflex timing pulleys are typically made from high-strength materials, such as aluminum and plastic composites, which provide durability and resistance to wear.

2. Tooth Design The unique tooth profile of Synchroflex pulleys enhances their ability to grip the timing belt, improving power transfer and reducing the likelihood of failure due to slippage.

3. Variety of Sizes These pulleys come in various sizes and configurations, catering to diverse mechanical needs. This adaptability makes them suitable for a wide range of applications, from small devices to large industrial machines.

4. Precision Engineering Synchroflex pulleys are manufactured with high precision, ensuring that they meet the stringent requirements of modern engineering standards.

Advantages of Using Synchroflex Timing Pulleys

1. Enhanced Performance Their robust design allows Synchroflex timing pulleys to maintain high levels of efficiency, which translates to improved performance in mechanical systems.

2. Reduced Noise and Vibration The seamless engagement of the pulley and belt minimizes operational noise and vibrations, contributing to a more pleasant working environment and prolonging the lifespan of the machinery.

synchroflex timing pulley

4. Adaptability They can be easily integrated into various mechanical systems, making them a versatile choice for engineers and designers.

Applications of Synchroflex Timing Pulleys

Synchroflex timing pulleys are used across a multitude of industries

- Manufacturing In automated assembly lines, they help synchronize movements, ensuring that machines operate smoothly and efficiently. - Automotive These pulleys play a pivotal role in automotive engines, where precise timing is necessary for optimal performance.

- Robotics In robotic systems, Synchroflex timing pulleys are used to transfer motion accurately, allowing for precise control of robotic limbs and joints.

- Textile Machines Their ability to manage high-speed movements makes them ideal for various textile manufacturing processes.

Best Practices for Implementation

1. Proper Installation To maximize the efficiency and lifespan of Synchroflex timing pulleys, it is crucial to install them according to the manufacturer's specifications. Misalignment can lead to increased wear and tear.

2. Regular Inspections Frequent checks will help identify any potential issues before they escalate. Inspecting for signs of wear on both the pulleys and belts will ensure optimal performance.

3. Use Compatible Components Always pair Synchroflex pulleys with the appropriate timing belts and other components to ensure compatibility and functionality.

4. Environmental Considerations Consider the operating environment, including factors such as temperature, humidity, and exposure to chemicals that could affect the materials used in the pulleys and belts.

Conclusion

In summary, Synchroflex timing pulleys stand out as an essential component in modern mechanical systems. With their durable construction, precision engineering, and adaptability across various industries, they offer significant advantages that enhance the performance of machinery and equipment. By following best practices during installation and maintenance, engineers can ensure longevity and reliability in their applications, making Synchroflex timing pulleys a wise investment in the machinery landscape.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

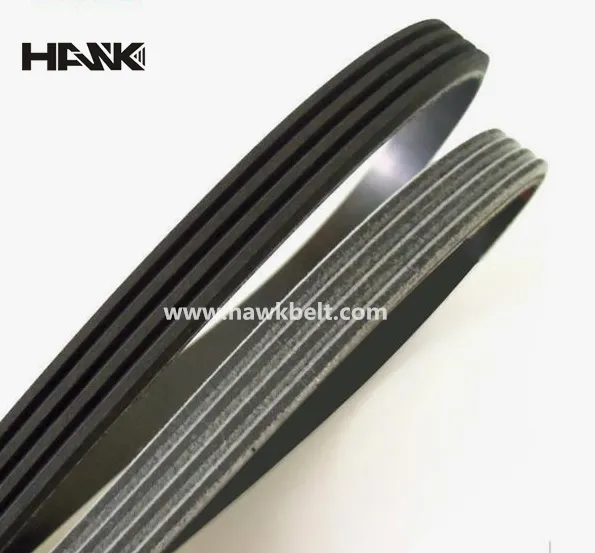

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025