- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

دسمبر . 05, 2024 14:52 Back to list

small flat belts

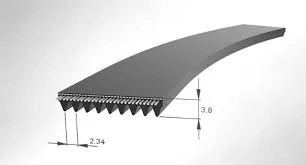

Understanding Small Flat Belts Design and Applications

Small flat belts are an integral part of mechanical systems and play a crucial role in the transfer of power from one component to another. These belts are characterized by their flat, flexible form and are commonly manufactured from a variety of materials, including rubber, fabric, and synthetic composites. The versatility and efficiency of small flat belts make them a popular choice in numerous applications, from small machinery to larger industrial setups.

Design Features of Small Flat Belts

Small flat belts are typically designed to handle lightweight tasks while maintaining efficiency and durability. A notable feature is their flat cross-section, which allows for a greater surface area contact with pulleys compared to round belts, resulting in improved grip and reduced slippage. The flexibility of the belt is crucial; it must be able to bend without losing its structural integrity, which makes materials like rubber or thermoplastics ideal for their fabrication.

The manufacturing process involves careful selection of materials to withstand varying degrees of tension and wear. Often, the belts are reinforced with fibers to enhance strength and elasticity. The thickness of small flat belts varies based on their specific application, and they are often customized to meet the requirements of different machinery or systems.

Advantages of Small Flat Belts

One of the main advantages of small flat belts is their ability to operate at high speeds while minimizing vibrations. Because of their flat shape, they can also be used in applications where space is limited. Their flat profile allows for easier installation and removal, which is beneficial for maintenance and repairs.

Small flat belts are also known for their high efficiency in power transmission. The larger surface area in contact with the pulley surfaces leads to better frictional engagement, ensuring that little energy is lost during transfer. This efficiency not only reduces operational costs but also enhances the overall performance of the machines in which they are utilized.

Moreover, these belts are less likely to generate heat when compared to other types of belts, reducing the need for cooling systems in some applications. This heat reduction contributes to a longer lifespan for both the belt and the machinery components.

small flat belts

Applications of Small Flat Belts

The applications of small flat belts are diverse, spanning various industries. In manufacturing, they are often employed in conveyor systems, where they help transport items smoothly and efficiently between different stages of production. They are also used in printers and other office equipment, where precise movements and reliability are critical.

In the automotive industry, small flat belts can be found in drive systems, helping to connect different components while maintaining the required tension and alignment. Additionally, they are widely used in agricultural machinery, such as seeders and harvesters, where durable and effective power transmission is essential.

The rise of electric and hybrid vehicles has also seen an increased demand for small flat belts, as these systems require lightweight yet robust solutions for power distribution within the vehicle.

Future Trends and Innovations

As technology advances, the future of small flat belts looks promising. Innovations in materials science are paving the way for the development of even more durable and efficient belts. For instance, advancements in synthetic materials can result in belts that are not only stronger but also lighter, enabling machines to operate more efficiently.

Additionally, as industries strive for sustainability, there is a growing emphasis on producing eco-friendly belts made from renewable resources. The integration of smart technologies into belt systems, such as sensors to monitor wear and performance, is also on the horizon. These developments could provide operators with valuable data to make informed decisions about maintenance and replacement, reducing downtime and enhancing productivity.

Conclusion

Small flat belts are a vital component in many mechanical systems, offering a blend of efficiency, durability, and versatility. As industries continue to evolve, the demand for innovative and effective power transmission solutions will likely drive further advancements in the design and application of small flat belts. Understanding their features, advantages, and applications can help businesses make informed choices in harnessing their potential for enhanced performance and productivity. As advancements unfold, small flat belts remain crucial in powering the machinery of the future, contributing to the ongoing evolution of various industries.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025