- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

دسمبر . 09, 2024 16:08 Back to list

pk belt alternator

Understanding the PK Belt Alternator A Comprehensive Overview

In the realm of automotive engineering, the alternator plays a crucial role in the efficient functioning of vehicles. Among the various types of alternators, the PK belt alternator stands out due to its design and operational advantages. This article aims to provide a detailed overview of the PK belt alternator, its working mechanism, applications, and maintenance tips.

What is a PK Belt Alternator?

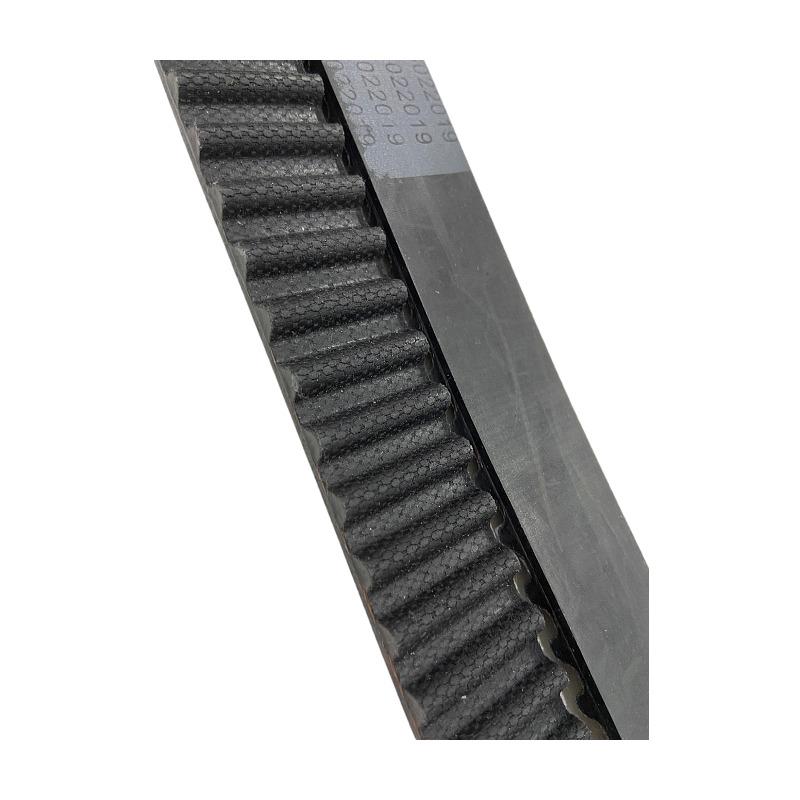

The PK belt alternator refers to an alternator that utilizes a PK (or Poly V) belt system for its operation. The PK belt system is characterized by its flat design and multiple ribs running parallel to the length of the belt. This design allows for a wider surface area in contact with the alternator pulley, enhancing grip and reducing slippage. The PK belt is commonly used in modern vehicles for power transmission purposes, and its integration with alternators brings several benefits.

How Does It Work?

The basic function of an alternator is to convert mechanical energy into electrical energy, which charges the battery and powers various electrical systems in a vehicle. In the case of a PK belt alternator, the process begins when the engine runs. The engine's rotation turns the crankshaft, which is connected to the alternator via the PK belt.

As the engine cranks, the rotational energy is transmitted through the PK belt to the alternator pulley. This rotation causes the rotor inside the alternator to spin, inducing a magnetic field. According to Faraday’s law of electromagnetic induction, this spinning magnetic field generates electrical current in the stator windings of the alternator. The result is an output of alternating current (AC), which is then converted into direct current (DC) through a built-in rectifier. This DC power is what charges the vehicle’s battery and powers the electrical systems.

Advantages of PK Belt Systems

1. Increased Efficiency The design of the PK belt allows for a greater surface area contact, thereby minimizing slippage. This ensures that the alternator operates more efficiently since more power is transmitted to it from the engine.

2. Compact Design The PK belt system is generally more compact when compared to traditional V-belt systems. This compactness not only saves space in the engine compartment but also reduces overall weight, contributing to better fuel efficiency.

3. Reduced Noise The ribbed design of the PK belt results in quieter operation than the conventional V-belt systems. This reduction in noise is beneficial for drivers who value a quieter driving experience.

4. Longevity PK belts typically have a longer lifespan compared to traditional belt systems, which translates into less frequent replacements and reduced maintenance costs over time.

pk belt alternator

Applications of PK Belt Alternators

PK belt alternators are widely used in various types of vehicles ranging from passenger cars to commercial trucks. Their ability to efficiently power increasing electronic components in vehicles makes them a preferred choice in modern automotive designs. This includes vehicles equipped with advanced infotainment systems, navigation, power windows, and other electronic conveniences.

In addition to passenger vehicles, PK belt alternators also find applications in industrial machinery and equipment where reliable electrical power generation is necessary. Their efficiency and compactness make them suitable for use in generators, vehicles, and other machinery that require a steady power supply.

Maintenance Tips

To ensure the longevity and optimal performance of a PK belt alternator, regular maintenance is essential. Here are some key maintenance tips

1. Inspect the Belt Regularly Check for signs of wear or damage on the PK belt. Look for cracks, fraying, or glazing, and replace the belt if any issues are detected.

2. Tension Adjustment Ensure that the belt is properly tensioned. A loose belt can lead to slippage and reduced efficiency, while a belt that is too tight can cause excessive wear.

3. Clean the Pulley Over time, dirt and grease can accumulate on the pulley, which may affect performance. Regularly cleaning the pulley will help maintain grip and efficiency.

4. Monitor Performance Keep an eye on the electrical systems of your vehicle. If you notice dimming lights or issues with starting the vehicle, it could indicate a problem with the alternator.

Conclusion

The PK belt alternator represents a significant advancement in automotive technology, offering enhanced efficiency, durability, and performance compared to traditional systems. Understanding how it works, its benefits, and how to maintain it can lead to better vehicle performance and longevity. As vehicles continue to evolve, the relevance of advanced components like the PK belt alternator will only increase, making it essential for both manufacturers and consumers to stay informed.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025