- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

اکتوبر . 04, 2024 18:55 Back to list

multiribbed belt

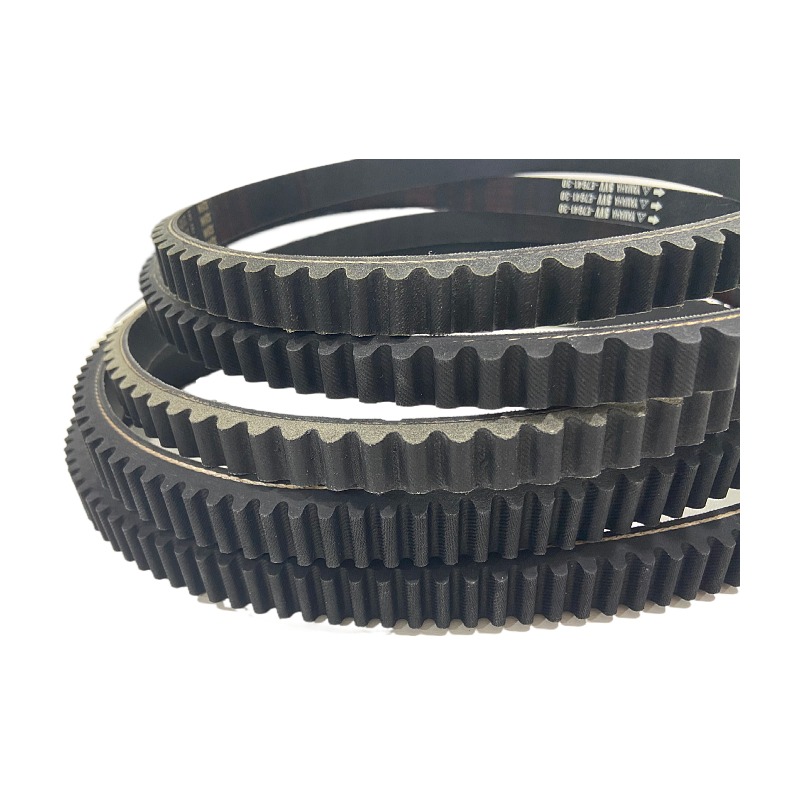

Understanding the Multiribbed Belt A Key Component in Modern Machinery

The multiribbed belt, often referred to as a serpentine belt or poly v-belt, is a crucial component used extensively in various mechanical systems. Its design not only optimizes performance but also contributes to the overall efficiency of machinery, particularly in automotive applications. This article aims to explore the features, applications, advantages, and maintenance aspects of multiribbed belts, highlighting their significance in today's industrial landscape.

What is a Multiribbed Belt?

A multiribbed belt is a type of drive belt characterized by multiple narrow ribs that run along its length. Unlike traditional V-belts, which have a wedge-shaped cross-section, multiribbed belts are flat with grooves on one side, allowing them to fit snugly onto the pulleys of different engine components. This design reduces slippage and increases the surface area in contact with the pulleys, leading to improved power transmission.

Applications of Multiribbed Belts

Multiribbed belts are predominantly found in automotive applications, where they connect various engine components, including the alternator, power steering pump, water pump, and air conditioning compressor. In addition to the automotive industry, these belts are utilized in agricultural machinery, construction equipment, and industrial applications that require a reliable means of power transmission between rotating parts.

The versatility of multiribbed belts allows them to be used in electric motors, conveyors, and other machinery where efficient torque transfer is essential. Their compact design enables manufacturers to minimize space without compromising functionality, making them an ideal choice for modern machines that demand high performance in limited areas.

Advantages of Multiribbed Belts

1. High Power Transmission Efficiency Thanks to their unique multi-ribbed design, these belts exhibit superior power transmission capabilities. They can efficiently handle high torque loads and minimize energy loss due to slippage.

2. Compact Design The slim profile of multiribbed belts allows for a tighter fit within machinery. This compactness contributes to a lighter overall weight of assemblies, which is particularly advantageous in automotive designs where weight reduction can enhance fuel efficiency.

3. Reduced Noise and Vibration Multiribbed belts generally produce less noise when operating compared to traditional V-belts. Their smooth contact with pulleys helps diminish vibrations, resulting in a quieter functioning of machinery.

multiribbed belt

4. Longer Lifespan With better wear resistance and lower operational stress, multiribbed belts often have a longer service life compared to their counterparts. This not only reduces the frequency of replacements but also minimizes maintenance costs.

5. Ease of Installation The flexible design of multiribbed belts makes them easier to install and remove, which is a critical factor during maintenance and repairs. This ease of handling saves time and enhances productivity.

Maintenance of Multiribbed Belts

To ensure optimal performance and longevity, proper maintenance of multiribbed belts is essential. Here are a few tips to maintain these belts effectively

1. Regular Inspections Routine checks for wear, cracks, or fraying can help identify issues before they lead to belt failure. Inspecting the tension and alignment of the belt is also critical to avoiding premature wear.

2. Proper Tensioning Keeping the belt at the correct tension is vital for effective power transmission. Over-tensioning can lead to premature wear, while under-tensioning can cause slippage.

3. Clean Environment Keeping the belt and pulleys clean from dust, oil, and debris can prolong the life of the belt. Contaminants can lead to slippage and increase wear.

4. Replacing Worn Belts Promptly It’s crucial to replace any belt showing signs of significant wear or damage. Waiting too long can result in engine failure or breakdowns, leading to costly repairs.

Conclusion

The multiribbed belt plays an indispensable role in the efficiency and reliability of many mechanical systems. Its innovative design and multiple advantages make it a preferred choice for numerous applications, particularly in the automotive industry. Understanding their functionality, applications, and maintenance can help users maximize the performance and longevity of these critical components. As technology advances, the design and materials used in multiribbed belts will continue to evolve, further enhancing their capabilities and applications in modern machinery.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025