- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Гру . 12, 2024 09:19 Back to list

xl timing belt

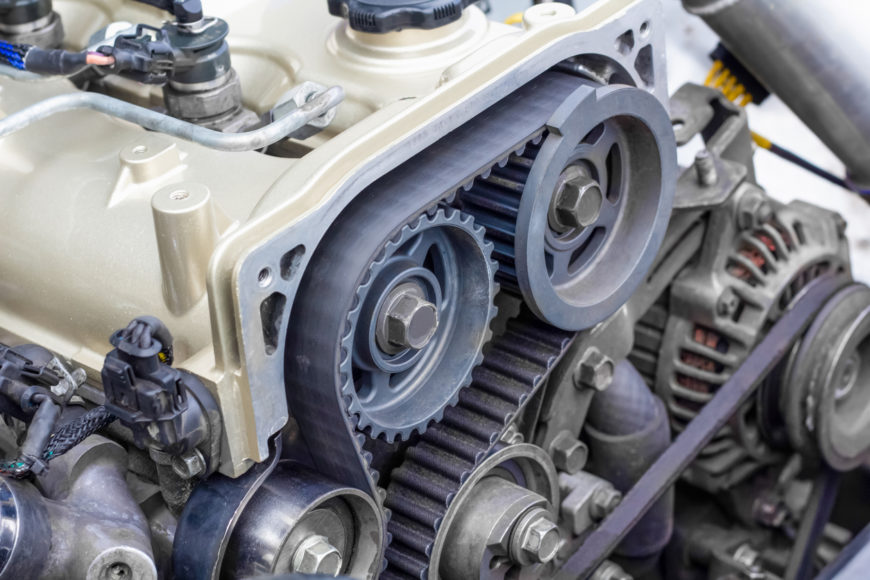

Understanding XL Timing Belts A Comprehensive Guide

In the world of mechanical engineering and precision machinery, timing belts play a crucial role in ensuring that components work together seamlessly. Among the various types of timing belts available, the XL timing belt is particularly noteworthy. This article delves into the specifics of XL timing belts, their applications, advantages, and how to maintain them for optimal performance.

What is an XL Timing Belt?

The term XL refers to the pitch size of the teeth on the timing belt. Specifically, the XL timing belt has a pitch of 0.2 inches (or 5.08 mm) between the centers of adjacent teeth. This makes it suitable for applications requiring precision and reliability. The belt is typically constructed from durable materials such as neoprene or polyurethane, which are specifically chosen for their ability to withstand wear and environmental factors.

XL timing belts are designed to drive pulleys and are often used in conjunction with synchronous drive systems. This means that both the timing belt and the pulleys work together harmoniously to ensure that the motion of one component is precisely synchronized with the motion of another, preventing slippage and maintaining timing accuracy.

Applications of XL Timing Belts

XL timing belts are versatile and find applications across various industries. Here are some common areas where they are used

1. Robotics In robotic systems, precision is paramount. XL timing belts help in the accurate and smooth operation of robotic arms and components, ensuring tasks are executed with high precision.

2. 3D Printers Many 3D printers utilize XL timing belts to control the movement of print heads and platforms. The belts allow for smooth and accurate positioning, which is essential for creating intricate designs.

3. Textile Machinery In the textile industry, timing belts drive sewing and weaving machines. The precision of the XL timing belt ensures consistent and reliable operation, reducing the risk of fabric defects.

4. Automotive Applications While XL timing belts are not typically used in engines, they can be found in systems such as power windows, sunroofs, and other auxiliary systems that require synchronization.

5. Conveyor Systems Many conveyor systems utilize XL timing belts to move products through various stages of production. Their durability and reliability make them an ideal choice for these applications.

Advantages of XL Timing Belts

The XL timing belt offers several advantages that make it a preferred choice in many applications

xl timing belt

1. Precision Timing The specific tooth design and pitch of the XL belt ensure that there is minimal play between the belt and the pulley, resulting in precise timing and reduced slippage.

2. Durability Made from high-quality materials, XL timing belts are designed to withstand wear and heat, making them suitable for long-term use in demanding environments.

3. Low Maintenance Unlike some mechanical systems, XL timing belts require minimal maintenance. Regular inspection is usually sufficient to ensure they are in good working order.

4. Versatility The range of sizes available means that XL timing belts can be tailored to fit a variety of applications, whether in industrial machinery or consumer products.

5. Cost-Effective Compared to other types of drive systems, timing belts tend to be more affordable both in terms of initial outlay and the overall operating costs.

Maintenance Tips for XL Timing Belts

To keep your XL timing belts in optimal condition, consider the following maintenance tips

1. Regular Inspection Periodically check the belt for signs of wear, such as fraying or cracking. If any damage is detected, replace the belt immediately.

2. Proper Tensioning Ensure that the timing belt is properly tensioned to avoid excess slack, which could lead to slippage or premature wear.

3. Clean Environment Keep the working environment clean to prevent dirt and debris from entering the system, which could cause damage to the belt.

4. Temperature Monitoring Avoid exposing the timing belt to extreme temperatures, as this can accelerate wear and affect performance.

5. Alignment Checks Ensure that the pulleys and belt are properly aligned to minimize stress on the belt and maximize its lifespan.

Conclusion

In summary, XL timing belts are an essential component in various mechanical systems, offering reliability, precision, and durability. Understanding their applications, benefits, and maintenance requirements can help users maximize the performance of their machinery and ensure long-term success in their projects. Whether in robotics, automotive applications, or industrial machinery, XL timing belts are a trusted solution for drive synchronization.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025