- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Гру . 01, 2024 14:45 Back to list

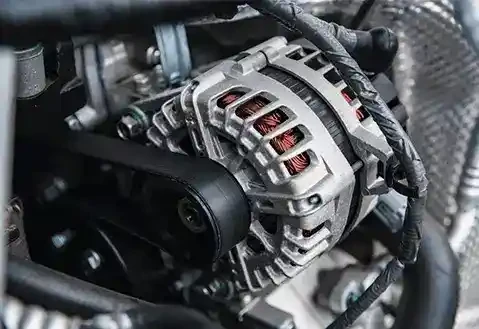

Comparison of Flat Belts and V Belts in Mechanical Applications

Flat Belts vs. V Belts A Comprehensive Comparison

When it comes to power transmission in mechanical systems, the choice of belt type can significantly impact efficiency, performance, and maintenance. Two of the most commonly used belt types are flat belts and V belts. Understanding their distinct features, advantages, and applications is crucial for engineers and technicians who design or maintain equipment that relies on these systems. In this article, we will delve into the characteristics of flat belts and V belts, comparing their efficiencies, uses, and maintenance needs.

Flat Belts A Classic Choice

Flat belts are one of the oldest forms of mechanical power transmission. These belts are typically made from flexible materials such as leather, rubber, or synthetic fabrics, and they have a flat surface design. Flat belts are used in a wide range of applications, from industrial machinery to conveyor systems.

One of the primary advantages of flat belts is their ability to transmit power over long distances. They can be used in applications where the distance between pulleys is significant, making them suitable for large machines or systems with multiple components. Additionally, flat belts operate quietly and have a low profile, allowing for compact machinery designs.

However, flat belts also have notable drawbacks. They can slip easily, especially under heavy loads or when misaligned, leading to inefficiencies and potential damage to machinery. Moreover, the flat design does not provide as much friction as V belts, which can limit their power transmission capabilities.

V Belts The Modern Solution

V belts, on the other hand, have a distinct trapezoidal shape that allows them to fit snugly into the grooves of V-shaped pulleys. This design enhances the frictional grip between the belt and the pulley, minimizing slippage, making V belts more effective for transmitting higher power loads. V belts are made from materials like rubber, which include various fabric and steel reinforcements for added strength and durability.

flat belt v belt

One of the significant advantages of V belts is their efficiency in power transmission. The design allows for better contact with the pulley, which means they can operate at higher speeds and load capacities compared to flat belts. Moreover, V belts are less susceptible to slippage, making them a preferred choice in applications where reliability and performance are critical, such as in automotive engines and industrial machinery.

However, V belts also come with some limitations. They generally require more precise alignment between pulleys to function effectively, and if they are not aligned correctly, they can wear out quickly. Additionally, V belts have a shorter lifespan compared to flat belts under certain conditions, especially in high-temperature environments.

Maintenance and Cost Considerations

When considering maintenance, flat belts often require less frequent adjustments and replacements compared to V belts, making them easier to maintain in some applications. However, their susceptibility to slippage can lead to increased wear on machinery over time.

In terms of cost, flat belts are generally cheaper than V belts, both in terms of the initial purchase price and maintenance. However, the overall cost of ownership for V belts may be lower due to their higher efficiency and longer service life in demanding applications.

Conclusion Choosing the Right Belt Type

In conclusion, the choice between flat belts and V belts largely depends on the specific requirements of the application. Flat belts are advantageous for long-distance transmission and easier maintenance, making them suitable for specific industrial applications. On the other hand, V belts excel in applications requiring high power transmission and reliability, despite their higher maintenance needs and cost.

Ultimately, understanding the unique advantages and limitations of each belt type allows engineers and technicians to make informed decisions that optimize performance while minimizing costs in mechanical systems. Whether it’s a flat belt or a V belt, ensuring the right choice will lead to improved efficiency, reduced downtime, and enhanced machinery longevity.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025