- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Лис . 05, 2024 18:01 Back to list

big v belt

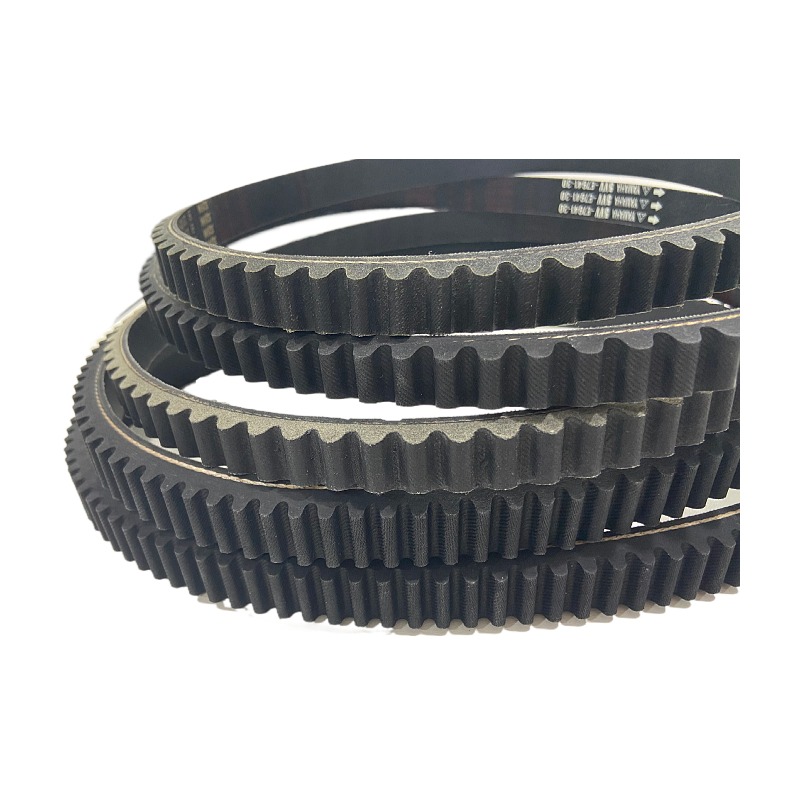

Understanding the Big V Belt A Key Component in Mechanical Systems

The big V belt is a ubiquitous element in many mechanical systems, often overlooked yet vital to the functioning of engines, industrial machinery, and various automotive applications. This flexible, continuous loop made of rubber or other elastic materials plays an essential role in transmitting power from one component to another, ensuring that machines operate smoothly and efficiently.

What is a Big V Belt?

A V belt is named for its distinctive V-shaped cross-section, which allows it to fit snugly in the pulleys it operates with. The big designation typically refers to its width and length, accommodating larger machinery that requires elevated power transfer capabilities. Big V belts are designed to handle higher loads and provide better traction compared to standard V belts, making them ideal for heavy-duty applications.

How Big V Belts Work

Big V belts transfer motion and power through friction. When a motor or engine turns a pulley, the belt's internal friction against the pulley causes it to move, thereby transferring power to another pulley connected to a different component, such as a fan, compressor, or another drive system. The V shape ensures that the belt grips the pulley securely, preventing slippage and increasing the efficiency of power transfer.

Applications of Big V Belts

The applications of big V belts are vast and varied. In automotive settings, they are commonly found in engines, where they drive components such as alternators, water pumps, and air conditioning units. Industrial machinery also relies on these belts to connect electric motors to equipment for operations ranging from conveyor belts to milling machines. In agriculture, big V belts are used in tractors and combines, efficiently powering implements for plowing, harvesting, and other tasks.

Advantages of Big V Belts

1. Durability Big V belts are manufactured to withstand substantial wear and tear due to their robust construction. They are resistant to heat, oil, and other environmental factors that could degrade performance.

big v belt

2. High Power Transmission Their larger size allows for greater power transmission, making them suitable for high-demand applications. They can handle heavier loads without slipping, which enhances overall efficiency.

3. Easy Installation and Maintenance Big V belts are relatively easy to install and replace. Regular maintenance, such as checking for wear and proper tension, ensures longevity and optimal performance.

4. Cost-Effective When compared to other power transmission methods, such as chains or gear drives, big V belts are often more affordable, making them a popular choice in various industries.

Maintenance Tips for Big V Belts

To ensure the longevity and proper functioning of big V belts, regular maintenance is essential. Here are some tips

- Check Tension Proper tension is crucial. A belt that is too loose may slip, while one that is too tight can cause undue wear on both the belt and the pulleys. - Inspect for Wear Regularly check the belt for signs of cracking, fraying, or glazing. Any visible damage can indicate that it's time for a replacement.

- Alignment Ensure that the pulleys are aligned correctly. Misalignment can lead to uneven wear and decreased efficiency.

- Cleanliness Keeping the belt and pulleys clean from oil, dirt, and debris will prolong the life of the belt and improve its performance.

Conclusion

In conclusion, the big V belt may be a small component in the grand scheme of machinery, but its importance cannot be understated. From powering essential automotive features to driving heavy industrial equipment, its role in the mechanical world is foundational. Understanding the function, applications, advantages, and maintenance of big V belts can help individuals and businesses maximize the efficiency and lifespan of their machinery. By investing time in proper care and installation, operators can ensure that these belts continue to perform reliably, contributing to the overall productivity and effectiveness of their equipment.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025