- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ноя . 06, 2024 02:18 Back to list

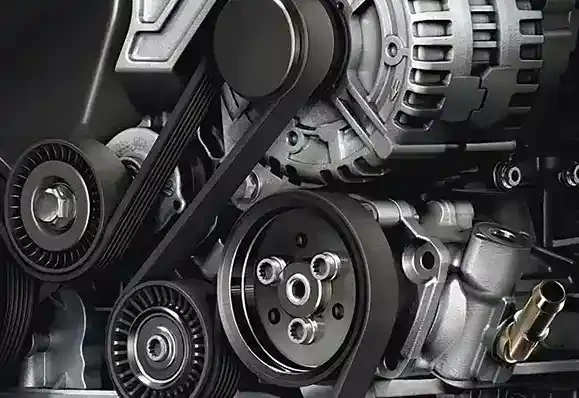

Understanding the Mechanics and Applications of V-Belt Drive Systems for Efficient Power Transmission

Understanding V-Belt Drives Principles, Applications, and Advantages

V-belt drives are widely used mechanical systems designed to transmit power between shafts. They utilize a flexible belt with a trapezoidal cross-section, enabling efficient and reliable power transmission in various industrial and commercial applications. This article delves into the fundamental principles behind V-belt drives, their applications, and the advantages they provide.

The Mechanism of V-Belt Drives

The basic design of a V-belt drive consists of a belt, pulleys (also known as sheaves), and a power source, such as an electric motor or an engine. The belt is positioned in the groove of pulleys, which helps to maintain proper alignment and reduces slippage. When the driving pulley (attached to the power source) turns, it engages the V-belt, which in turn rotates the driven pulley.

One of the key principles behind the operation of V-belt drives is the wedging effect. The unique shape of the V-belt allows it to sit snugly in the pulley groove. This wedging action increases friction between the belt and the pulley, thus enabling a higher torque transmission compared to flat belts. The ability to securely grip the pulleys ensures effective power transfer, making V-belt drives highly efficient.

Types of V-Belts

There are several types of V-belts available, each tailored to specific requirements

1. Classical V-Belts These are the most common type, available in different sizes based on the application. They are reliable and widely used in various machines.

2. Narrow V-Belts These belts are designed with a narrower profile and are used to transmit power in smaller spaces. They offer higher power transmission capabilities relative to their size.

3. Joined V-Belts These belts are made by connecting multiple belts into a single long length, which is useful for high-torque applications.

4. Variable Speed V-Belts These belts can be adjusted for speed variation, making them ideal for applications where speed control is crucial.

Applications of V-Belt Drives

V-belt drives are employed in numerous applications across various industries, including

- Manufacturing Used in conveyor systems, mixers, and machinery to transmit power efficiently. - HVAC Systems Commonly found in fans, blowers, and compressors to regulate airflow and temperature.

v belt drive

- Agriculture Utilized in tractors and machinery for plowing, tilling, and harvesting.

- Automotive Seen in many vehicles, V-belts drive the alternator, air conditioning compressor, and power steering pump.

- Construction Often used in heavy equipment such as cranes and excavators to manage mechanical systems.

Advantages of V-Belt Drives

The popularity of V-belt drives in various applications can be attributed to several advantages

1. High Efficiency With their ability to transmit power with minimal losses, V-belt drives are among the most efficient systems available.

2. Flexibility V-belts can accommodate various center distances and ease of installation, making them versatile in different setups.

3. Cost-Effectiveness They offer a competitive initial investment compared to other power transmission methods.

4. Noise Reduction V-belt drives operate more quietly than chain drives, making them ideal for environments where noise levels need to be kept to a minimum.

5. Durability With proper maintenance, V-belts can have long service lives, which reduces the need for frequent replacements.

6. Load Isolation V-belt drives help to isolate the load between the motor and the driven components, which can prolong the life of machinery and reduce wear.

Conclusion

V-belt drives are a fundamental technology in mechanical power transmission, offering efficiency, versatility, and reliability. Their ability to transmit power smoothly across various industries makes them integral to modern machinery and systems. Whether in manufacturing, automotive, or agricultural applications, understanding the principles and benefits of V-belt drives can assist engineers and technicians in selecting the right system for their specific needs. As technology advances, the design and materials of V-belts are expected to evolve, further enhancing their performance and adaptability in a dynamic industrial landscape.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025