- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Сен . 29, 2024 02:26 Back to list

Double Tooth V-Belt Design for Enhanced Power Transmission Efficiency

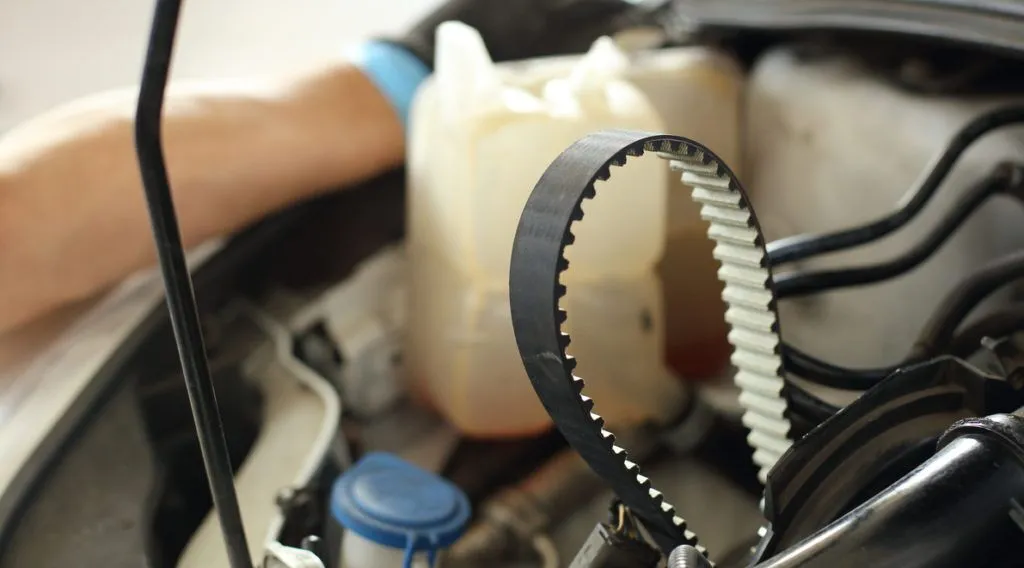

Understanding V-Belt Double Teeth A Comprehensive Overview

When we discuss mechanical systems and their efficiency, one critical component often comes to mind the V-belt. Among various types of belts used in machinery, the V-belt is renowned for its unique design and functionality, particularly in terms of power transmission. A specialized version of this is the V-belt with double teeth, which enhances its performance in specific applications. In this article, we will explore the characteristics, advantages, and applications of the V-belt double teeth.

What is a V-Belt?

A V-belt is a rubber belt that has a cross-section shaped like a V. This design allows it to fit snugly into grooves on pulleys, creating a larger contact area, which improves grip and power transmission. Traditionally, V-belts have been employed in various machinery, including motors, fans, and conveyor systems, due to their reliable performance and durability.

The Role of Double Teeth

The introduction of double teeth in the V-belt design significantly augments its functions. Standard V-belts provide a good grip on pulleys; however, they may slip under heavy loads or high-speed conditions. Double-tooth V-belts feature an additional tooth profile on the inner surface, which increases the surface area in contact with the pulley. This added contact ensures better engagement and minimizes slippage, a common issue in high-torque applications.

Advantages of V-Belt Double Teeth

1. Enhanced Grip and Reduced Slippage The primary benefit of double teeth is their ability to grip the pulley more effectively. This design ensures maximum power transmission efficiency, leading to improved overall performance of the machinery.

2. Higher Load Capacity Due to the increased contact surface and improved traction, V-belts with double teeth can handle higher loads without compromising on performance. This capability makes them ideal for heavy-duty applications.

3. Reduced Noise and Vibration Traditional V-belts can produce noise and vibrations during operation, especially when slipping occurs. The advanced design of double-tooth belts facilitates smoother operations, resulting in less noise and reduced wear and tear on the machinery.

v belt double teeth

4. Extended Lifespan By minimizing slippage and improving grip, double-tooth V-belts tend to last longer than their standard counterparts. The reduced fatigue on the material translates to a lower frequency of replacements, ultimately saving costs in maintenance and downtime.

5. Versatile Applications The robust nature of V-belts with double teeth allows for diverse applications across different industries. From manufacturing and automotive to agricultural machinery, these belts are suitable for environments that require high performance and reliability.

Applications of V-Belt Double Teeth

Due to their unique advantages, V-belt double teeth are widely used in various settings

- Industrial Machinery In factories and production lines, these belts drive equipment such as conveyor systems, mixers, and milling machines, where reliability under heavy loads is paramount.

- Automotive Sector Many vehicles rely on belts to connect engines to different systems, such as alternators and air conditioning compressors. V-belts with double teeth can handle the higher stresses found in these applications, ensuring efficient operation.

- Agricultural Equipment Farming machinery, such as tractors and harvesters, often operates under tough conditions. Double-tooth V-belts provide the necessary robustness to handle the variable loads encountered in this sector.

- HVAC Systems In heating, ventilation, and air conditioning applications, the ability of a V-belt to perform reliably under varying conditions is critical. Double-tooth V-belts excel in these environments, ensuring energy efficiency and consistent performance.

Conclusion

In summary, the V-belt double teeth represents an advanced iteration of a vital component in mechanical systems. With enhanced grip, higher load capacity, reduced noise, and a longer lifespan, these belts are indispensable in ensuring that machinery operates smoothly and efficiently. As industries continue to seek ways to optimize performance and reliability, it is evident that V-belt double teeth will play a significant role in shaping the future of machinery design and operational efficiency. Whether you are involved in manufacturing, automotive, or agriculture, understanding the benefits of these belts can help in making informed decisions that enhance productivity and reduce costs.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025