- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ноя . 21, 2024 05:28 Back to list

v belt double teeth

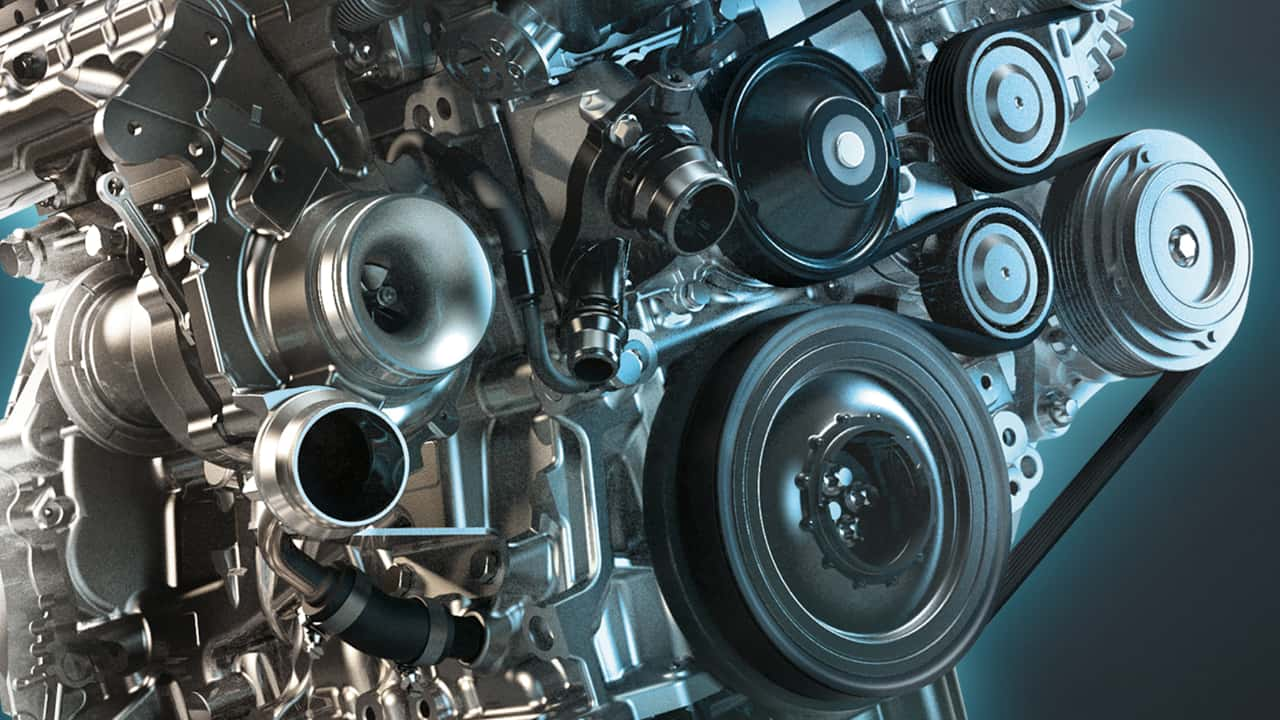

Understanding V-Belt Double Teeth An Essential Component in Machinery

In the realm of mechanical engineering and industrial machinery, the efficiency and reliability of power transmission systems are paramount. One of the unsung heroes in this arena is the V-belt, particularly the double tooth variant, which serves crucial roles in various applications. This article delves into the nuances of V-belt double teeth, exploring their design, benefits, applications, and maintenance.

What is a V-Belt?

A V-belt is a type of belt that has a trapezoidal cross-section, which allows it to fit snugly into a matching groove on a pulley. This design facilitates the effective transfer of power from one component to another. V-belts are preferred in many applications due to their flexibility, efficiency, and ability to handle high-speed operations.

The Double Tooth Design

The double tooth V-belt features two sets of teeth along its length, which engage with corresponding grooves in the pulleys. This design enhances grip and provides a larger surface area for power transmission. Double teeth increase the belt's contact with the pulley, which significantly reduces slippage and improves the belt's overall torque transmission capacity.

Advantages of Double Tooth V-Belts

1. Increased Torque Transmission The dual-tooth design maximizes the contact area, enabling the belt to transfer more torque without compromising performance. This is particularly beneficial in heavy-duty applications where substantial power is required.

2. Reduced Slippage The additional teeth ensure a tighter grip on the pulley, which minimizes slippage. This is crucial in applications requiring precise timing, such as in conveyor systems or mechanical timing applications.

3. Lower Vibration Levels V-belts with a double tooth configuration tend to accumulate fewer vibrations compared to traditional single-tooth belts. This leads to smoother operation and enhances the lifespan of both the belt and associated machinery.

4. Improved Durability The enhanced design reduces wear and tear. Double tooth V-belts typically have higher resistance to fatigue, temperature changes, and environmental factors, leading to fewer replacements and lower maintenance costs over time.

5. Versatility Double tooth V-belts are adaptable to a wide range of applications, from automotive engines to industrial machinery. Their design allows for use in both high and low-speed environments.

Applications of Double Tooth V-Belts

v belt double teeth

The versatility of double tooth V-belts makes them suitable for various sectors

- Automotive In vehicles, double tooth V-belts are commonly used in drive systems to transfer power from the engine to various components, including the alternator, water pump, and air conditioning compressor.

- Industrial Machinery In factories and assembly lines, these belts power conveyors, pumps, and compressors, ensuring smooth and efficient operation.

- Agriculture Farming equipment, including tractors and harvesters, often employs double tooth V-belts for reliable performance under heavy load conditions.

- HVAC Systems Heating, ventilation, and air conditioning systems utilize these belts for efficient blower and fan operations.

Maintenance Tips

To ensure that double tooth V-belts operate at peak performance, regular maintenance is essential

1. Inspect for Wear Regularly check the belt for signs of wear, including cracks, fraying, or any deformation.

2. Check Tension Ensure that the belt is properly tensioned. A belt that is too loose can lead to slippage, while one that is too tight can cause premature wear on pulleys and bearings.

3. Align Pulleys Misalignment can lead to uneven wear and reduced efficiency. Regularly check and realign pulleys if necessary.

4. Cleanliness Keep the belt free from oil, dirt, and debris, as contaminants can affect performance and lead to premature failure.

Conclusion

In conclusion, V-belt double teeth are invaluable components that enhance the effectiveness of power transmission systems across sectors. Their ability to transmit higher torque, minimize slippage, and reduce vibrations make them a preferred choice in various applications. With proper maintenance, these belts can greatly contribute to the longevity and efficiency of machinery, ensuring reliable performance for years to come. Understanding their capabilities and applications is essential for engineers and technicians who strive to optimize their power transmission systems.

-

High-Performance Serpentine Belt for Car Engines – Durable & Reliable

NewsJul.23,2025

-

High Efficiency V Belt Drive with Double & Toothed Options for Industry

NewsJul.22,2025

-

Affordable Fan Belt Cost - Compare Prices & Save | Auto Parts Deals

NewsJul.22,2025

-

China Factory 6PK1130 EPDM Rubber Engine Conveyor Belt Supplier

NewsJul.21,2025

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025