- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Дек . 17, 2024 13:43 Back to list

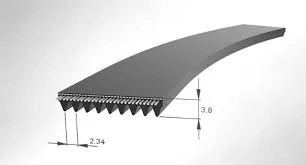

Understanding the Functionality and Benefits of Toothed Belts in Machinery

Understanding Toothed Belts An Essential Component in Modern Mechanical Systems

Toothed belts, also known as timing belts, play a crucial role in various mechanical systems, providing efficient power transmission while ensuring precise synchronization between components. Their unique design features evenly spaced teeth that engage with pulleys, allowing for smooth operation and reduced slip compared to traditional flat belts. This article delves into the principles, applications, advantages, and maintenance of toothed belts.

The Mechanism Behind Toothed Belts

Toothed belts are made from durable materials such as rubber or polyurethane, often reinforced with fiberglass or steel for additional strength. The design involves a series of teeth that fit into corresponding grooves on the pulleys. This interlocking mechanism allows for a positive drive, enabling the belt to transmit motion without slipping. The precise engagement of teeth ensures that rotational motion is transferred accurately, making toothed belts ideal for applications where timing is critical, such as in automotive engines and robotics.

The length of the toothed belt, the number of teeth, and the pitch (the distance between the centers of adjacent teeth) are all critical factors that affect the performance of the system it operates within. Proper tensioning of the belt is also necessary to maintain optimal performance and prevent premature wear.

Applications of Toothed Belts

Toothed belts are used in a wide range of applications across various industries. In the automotive sector, they are commonly found in timing belt systems that synchronize the crankshaft and camshaft, ensuring that the engine's valves open and close at the right times. This synchronization is vital for engine performance and efficiency.

In the manufacturing world, toothed belts are frequently employed in conveyor systems, CNC machines, and 3D printers. These belts provide accurate linear motion and control, which is essential in automated processes where precision is paramount. The use of toothed belts in these applications not only enhances reliability but also reduces maintenance costs due to their longevity compared to other drive systems.

Moreover, toothed belts are also seen in other areas such as home appliances, such as washing machines, where they transfer motion from the motor to the drum, and in office equipment like printers and copiers

.Advantages of Toothed Belts

The key benefits of toothed belts include

1. Precision Their synchronized design ensures accuracy in motion transfer, making them ideal for applications requiring exact timing.

toothed belt

2. Low Maintenance Unlike chain drives or gear systems, toothed belts require minimal lubrication and maintenance, which leads to lower operational costs.

3. Noise Reduction Toothed belts operate more quietly than chain drives, making them preferable in environments where noise is a concern.

4. Lightweight Design Typically, toothed belts are lighter than other power transmission systems, which contributes to energy efficiency.

5. Flexibility They can be designed in various sizes and configurations, making them adaptable to different machine designs.

Maintenance Tips for Toothed Belts

To ensure the longevity and proper functioning of toothed belts, regular maintenance is essential. Here are some tips

1. Check Tension Ensure that the belt is properly tensioned. A belt that is too loose may slip, while one that is too tight could lead to premature wear.

2. Inspect for Wear Regularly inspect the belt for signs of wear or damage, such as fraying or missing teeth. Addressing these issues promptly can prevent more significant problems down the line.

3. Alignment Ensure that the pulleys are aligned correctly. Misalignment can lead to uneven wear and increased risk of belt failure.

4. Environment Keep the belts free from contaminants like oil, grease, and debris, which can degrade the material and affect performance.

In conclusion, toothed belts are a fundamental component in many mechanical systems, providing reliable and efficient power transmission. Their advantages in precision, maintenance, noise reduction, and flexibility make them the preferred choice across various sectors. By understanding their mechanisms and implementing proper maintenance practices, users can ensure optimal performance and longevity of these vital components.

-

China Factory 6PK1130 EPDM Rubber Engine Conveyor Belt Supplier

NewsJul.21,2025

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025