- Arapça

- Fransızca

- Rusça

- İspanyol

- Portekizce

- Türkçe

- Ermeni

- İngilizce

- Arnavut

- Amharca

- Azerice

- Bask

- Belarusça

- Bengalce

- Boşnakça

- Bulgarca

- Katalanca

- Cebuano

- Korsikalı

- Hırvat

- Çek

- Danimarka

- Flemenkçe

- Afrikalı

- Esperanto

- Estonyalı

- Fince

- Frizce

- Galiçyaca

- Gürcü

- Almanca

- Yunan

- Gujarati

- Haiti Kreyolu

- Hausa

- Hawaii dili

- İbranice

- Hayır

- Miao

- Macarca

- İzlandaca

- İbo

- Endonezya dili

- İrlandalı

- İtalyan

- Japonca

- Cava

- Kannadaca

- Kazak

- Kmer

- Ruanda

- Koreli

- Kürt

- Kırgız

- TB

- Latince

- Letonca

- Litvanyalı

- Lüksemburgca

- Makedonca

- Malgaşi

- Malayca

- Malayalam

- Malta dili

- Maori

- Marathi

- Moğolca

- Myanmar

- Nepalce

- Norveççe

- Norveççe

- Oksitanca

- Peştuca

- Farsça

- Lehçe

- Pencap

- Romen

- Samoalı

- İskoç Galcesi

- Sırpça

- İngilizce

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovence

- Somalili

- Sundan dili

- Svahili

- İsveççe

- Tagalogca

- Tacikçe

- Tamilce

- Tatar

- Telugu

- Tay dili

- Türkmence

- Ukrayna

- Urduca

- Uygur

- Özbekçe

- Vietnam

- Galce

- Yardım

- Yidiş

- Yoruba

- Zuluca

May . 23, 2025 09:56 Listeye geri dön

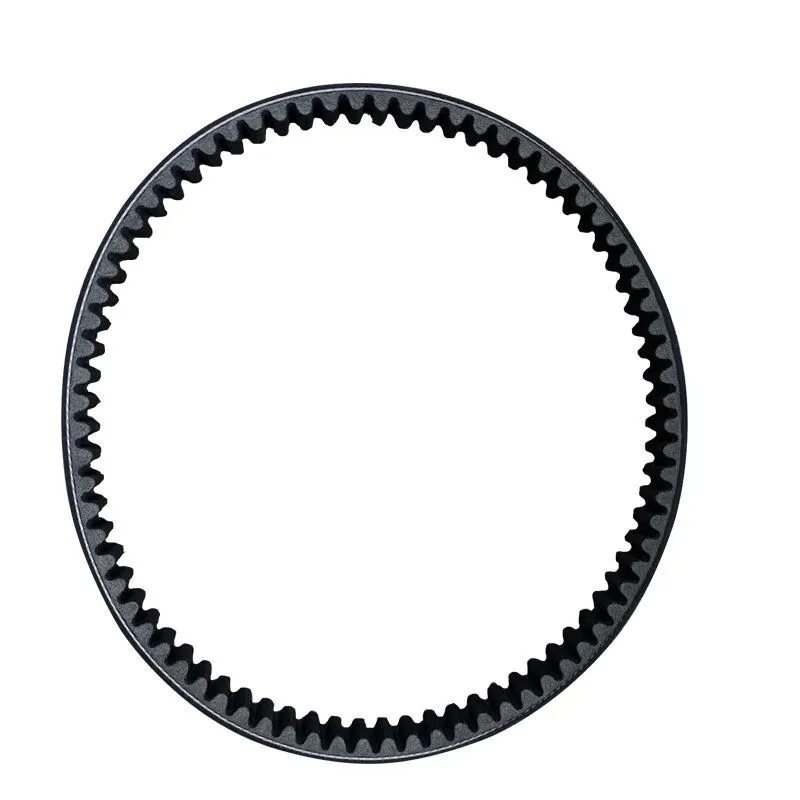

Revolutionize Power Transmission with Precision: The Unmatched Reliability of the Linked V Belt

In the world of industrial machinery and mechanical maintenance, efficiency, flexibility, and dependability are everything. Enter the linked v belt—a modern solution that combines traditional V-belt power with the innovation of modular design. Whether you’re facing unusual pulley arrangements, urgent replacements, or fine-tuning power output, the linked v belt outperforms expectations in more ways than one. This article delves into expert installation techniques, long-term performance benefits, and the crucial importance of tension control, while also showcasing the adaptability of the adjustable v belt and popular sizing options like the a46 v belt.

Smart Installation Tips for Linked V Belts

Installing a linked v belt requires a slightly different approach compared to traditional molded V-belts, but that’s where its greatest convenience lies. The modular construction allows users to customize the length without special tools—just cut to size and link it in. This is ideal for tight spaces or emergency repairs when factory-molded belts aren’t readily available.

When installing, it's essential to align the belt properly with the pulleys to ensure smooth and efficient motion. Misalignment can cause wear or even slipping. For applications using multiple belts, ensure all are of equal tension for even load distribution. The adjustable v belt offers additional flexibility, especially in applications with variable center distances or where pulley access is limited.

A properly installed linked v belt should have a deflection of about 1/64 inch per inch of span when moderate pressure is applied. Over-tensioning may lead to premature bearing wear, while under-tensioning can reduce torque efficiency and increase vibration.

Durability and Service Life of Linked V Belts

One of the standout features of the linked v belt is its remarkable durability in even the harshest operating environments. Unlike traditional belts, which can snap under tension or degrade from oil and chemical exposure, these belts are made from high-performance polyurethane elastomers reinforced with rugged polyester fabrics.

This construction provides superior resistance to abrasion, heat, and industrial fluids, meaning longer life cycles and fewer changeouts. In high-friction environments or settings where continuous operation is critical, the adjustable v belt resists elongation and cracking, maintaining performance over months of constant use.

Moreover, the segmented design of the linked v belt makes it possible to replace only worn segments rather than the entire belt, reducing both downtime and material waste. Even the a46 v belt, a frequently used size in HVAC and light industrial applications, demonstrates this superior longevity when manufactured in linked format.

Linked V Belts:The Hidden Risks of Loose Installation

Installing a linked v belt too loosely can lead to more than just annoying squeals—it can spell disaster for system performance. When a belt lacks the necessary tension, it fails to grip the pulley effectively, which reduces torque transmission and causes slippage. This slippage creates heat, accelerates wear, and can even cause belt segments to dislodge or pulleys to glaze over time.

Additionally, under-tensioned belts increase system vibration, which not only impacts the bearings and shafts but can ripple through to the entire machine, reducing its precision and lifespan. For motor-driven applications, this could also lead to inconsistent speeds and load irregularities.

A key benefit of the adjustable v belt is the ability to dial in the exact length and tension needed for the job, even on-site. Whether you're adjusting the belt on a factory conveyor, agricultural implement, or air handler unit, the ability to fine-tune the tension ensures optimal energy transfer and minimizes maintenance calls.

Versatility Across Applications: Linked V Belts in Motion

The linked v belt is a true workhorse, used in a wide range of industries from woodworking and textile production to HVAC and food processing. Its modular nature makes it ideal for non-standard setups where access is limited or where machines must be adapted on the fly.

For industries that rely on quick repair cycles, the linked v belt reduces inventory complexity since a single roll can be cut to size for multiple applications—including popular lengths like the a46 v belt. This allows service technicians and maintenance teams to work faster and smarter, without waiting on specific parts.

Meanwhile, the adjustable v belt ensures ongoing performance even in variable load conditions. Machines that deal with start-stop cycles, fluctuating speeds, or heavy torque applications can rely on consistent grip and alignment without the stretching problems of traditional belts.

Linked V Belt FAQs

What makes a linked v belt better than a traditional V-belt?

The linked v belt is modular, allowing users to easily customize its length without special tools. It also provides greater resistance to chemicals, heat, and abrasion, making it more durable in demanding conditions.

Can I use a linked v belt in place of my standard a46 v belt?

Yes, you can. As long as you match the length and cross-section, a linked v belt can serve as a replacement for standard sizes like the a46 v belt, with added benefits such as flexibility and quick installation.

How tight should I install a linked v belt?

The belt should have about 1/64 inch of deflection per inch of span under moderate finger pressure. Avoid over-tightening, as it may damage bearings. Undue looseness, however, can cause slippage and reduced torque.

How long does a typical adjustable v belt last?

With proper installation and regular maintenance, a high-quality adjustable v belt can last as long or even longer than conventional belts—often several thousand hours depending on the application.

Are linked v belts suitable for high-temperature environments?

Yes. They are made of temperature-resistant materials that perform well in high-heat environments, especially when compared to standard rubber V-belts.

-

Why Upgrade Performance with Precision Timing Belt Systems?

HaberlerJul.21,2025

-

Stationary Engine Flat Belts Revolutionize Your Power Transmission Needs?

HaberlerJul.21,2025

-

Discover Why Mens Motorcycle Belts Are Essential for Every Rider

HaberlerJul.21,2025

-

Discover How Vintage Motorcycle Belts Elevate Rider Style and Safety

HaberlerJul.21,2025

-

Could Innovation in Timing Belts Redefine Power Transmission Efficiency?

HaberlerJul.21,2025

-

Can Motorcycle Belts Improve Your Riding Comfort and Safety?

HaberlerJul.21,2025