- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 03, 2024 08:12 Back to list

Understanding the Functions and Importance of Serpentine Belts in Vehicles

Understanding the Use of Serpentine Belts in Modern Vehicles

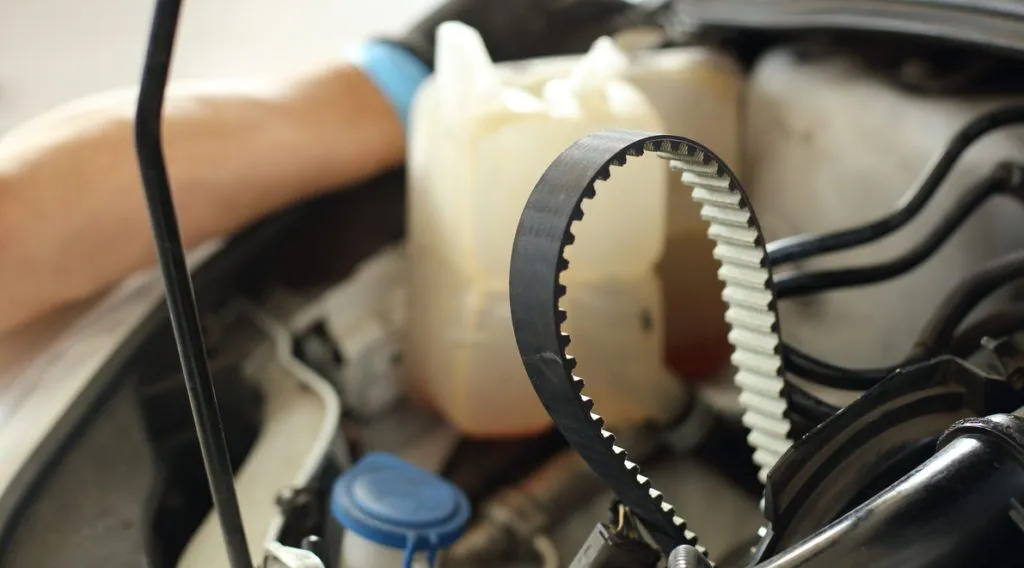

The serpentine belt, a vital component in most modern vehicles, plays a crucial role in ensuring the efficient functioning of the engine and various ancillary systems. This single, long belt snakes around multiple pulleys and drives several accessories, including the alternator, power steering pump, water pump, and air conditioning compressor. Understanding the functionality, maintenance, and replacement of serpentine belts is essential for vehicle owners to keep their cars running smoothly.

The Function of the Serpentine Belt

The primary function of the serpentine belt is to transfer rotational power from the engine's crankshaft to various accessories. In essence, as the engine runs and the crankshaft turns, the serpentine belt also turns, powering these essential components. This direct connection allows for better energy efficiency compared to older vehicles that relied on separate belts for different accessories. The serpentine belt's design not only reduces the number of components but also minimizes weight, enhancing fuel efficiency and reducing engine strain.

Common Problems and Signs of Wear

Despite their durability, serpentine belts are not immune to wear and tear. Over time, they can become cracked, frayed, or worn down, leading to a range of issues. One of the most noticeable signs of a faulty serpentine belt is unusual noises coming from the engine compartment, often described as squealing or chirping sounds. This sound is typically indicative of slippage or misalignment. Additionally, drivers may notice issues with power steering or difficulty in the operation of the vehicle's cooling system if the belt is in poor condition.

Other visual signs of wear can include cracks on the belt surface, fraying edges, or shiny areas indicative of slipping against pulleys. Regular inspection of the serpentine belt during routine vehicle maintenance can help identify these issues before they lead to more serious problems.

serpentine belt use

Replacement and Maintenance

Replacing a serpentine belt is crucial for maintaining the overall health of a vehicle. Most manufacturers recommend checking the belt every 60,000 to 100,000 miles, although this can vary based on the specific vehicle model and operating conditions. When replacing the belt, it is usually advisable to also inspect the associated pulleys and tensioner. A failing tensioner can lead to improper belt tension, risking further damage and premature failure of the new belt.

The process of replacing a serpentine belt can vary in complexity depending on the vehicle. While some drivers may choose to undertake this task themselves with proper tools and instructions, many opt for professional service to ensure it is done correctly.

Benefits of a Well-Maintained Serpentine Belt

Maintaining a serpentine belt not only contributes to a well-running engine but also enhances overall vehicle reliability. A well-functioning belt ensures that vital systems such as the alternator and water pump operate effectively, supporting battery charging and engine cooling. Consequently, this helps in avoiding costly repairs related to engine overheating or electrical failure.

In conclusion, the serpentine belt is a crucial component of modern vehicles that deserves attention and care. Understanding its function, recognizing signs of wear, and adhering to a maintenance schedule can significantly prolong its life and maintain the vehicle's performance. Regular checks and timely replacements not only ensure a smoother driving experience but also safeguard against unexpected breakdowns, leading to a safer and more economical vehicle operation in the long run. By prioritizing serpentine belt maintenance, drivers can enjoy peace of mind knowing that their vehicle is performing at its best.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025