- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ต.ค. . 02, 2024 17:28 Back to list

synchroflex belt

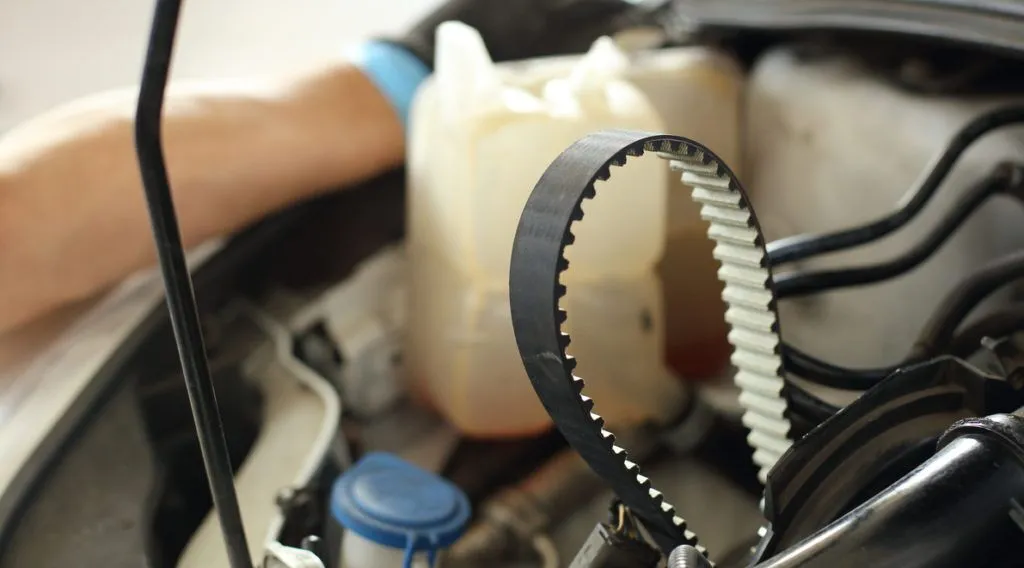

Understanding Synchroflex Belts A Key Component in Mechanical Systems

In the world of mechanical engineering, precision and reliability play crucial roles in the performance of machines. One of the essential components that ensure smooth operations in various mechanical systems is the synchroflex belt. This specialized type of timing belt is known for its excellent performance and adaptability in different applications.

What is a Synchroflex Belt?

A synchroflex belt, often referred to as a timing belt, is a toothed belt used in synchronizing the rotation of two or more shafts. Unlike traditional V-belts, synchroflex belts feature precisely engineered teeth that fit into corresponding grooves on pulleys. This design allows for accurate timing and eliminates the slippage common in other belt systems. The synchroflex belt transmits power effectively between the driving and driven components, making it ideal for applications requiring exact timing control.

Advantages of Synchroflex Belts

1. High Efficiency One of the most significant benefits of synchroflex belts is their efficiency in power transmission. The direct engagement of teeth minimizes energy loss, ensuring that most of the power generated by the engine or motor is used effectively.

2. Noise Reduction Operating with a synchroflex belt results in lower noise levels compared to chain drives and V-belts. This quality makes them suitable for applications in environments where noise reduction is critical.

synchroflex belt

3. Maintenance-Free Unlike chains that require regular lubrication, synchroflex belts operate maintenance-free under normal conditions. This reduces downtime and maintenance costs, making them a popular choice for manufacturers.

4. Compact Design The compact nature of synchroflex belts allows for more flexible system designs, saving space in machinery without compromising performance.

5. Versatility Synchroflex belts can be used in various applications ranging from automotive engines to robotics, food processing machinery, and HVAC systems. Their adaptability makes them valuable across many industries.

Applications of Synchroflex Belts

Synchroflex belts have found extensive use in various fields. In the automotive industry, they are commonly employed to connect the crankshaft to the camshaft, ensuring precise timing of the engine's valves. In industrial machinery, they drive conveyor systems and other equipment requiring synchronized motion. Additionally, they are vital in packaging machines, where accurate positioning is critical for efficiency.

Conclusion

In conclusion, synchroflex belts are indispensable components in modern mechanical systems. Their design offers numerous benefits, including high efficiency, noise reduction, and maintenance-free operation. As technology evolves, the demand for precision and reliability in machinery continues to grow, making synchroflex belts a cornerstone of mechanical engineering applications. Whether in automotive engines or complex industrial systems, synchroflex belts contribute significantly to performance, showcasing the importance of choosing the right equipment for the task at hand. With their myriad advantages, synchroflex belts will undoubtedly remain a preferred choice in diverse engineering applications for years to come.

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025

-

Timing Belt Video Guide: Selection, Design & Quality Insights

NewsJul.30,2025