- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ต.ค. . 15, 2024 17:30 Back to list

10 pack of durable belts for everyday use in various sizes and styles

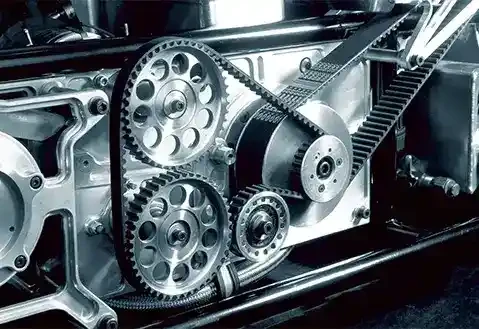

Understanding the Dynamics of 10PK and PK Belts in Industrial Applications

In the realm of industrial machinery and equipment, the choice of belts is crucial for optimized performance and efficiency. Among the various options available, the 10PK and PK belts have drawn significant attention due to their reliability and effectiveness in power transmission. This article aims to delve deeper into the characteristics, applications, and advantages of the 10PK and PK belts.

The Basics What are 10PK and PK Belts?

Belts play an instrumental role in transferring power between different components of a machine. The designation 10PK and PK indicates certain specifications, particularly the number of ribs and the belt's width. The 10 in 10PK signifies the number of ribs in the belt, while PK stands for the profile of the belt commonly used in industrial applications.

PK belts are typically made from high-quality rubber or advanced materials designed to withstand substantial tension and mechanical wear. The '10' indicates that the belt has 10 ribs or grooves, allowing for better contact with pulleys, which results in improved performance and power transfer efficiency.

Applications of 10PK and PK Belts

10PK and PK belts are widely utilized across various industries, including automotive, manufacturing, and agricultural sectors. They are essential in systems that require efficient transmission of power, such as conveyor systems, fans, compressors, and various machinery.

1. Automotive Applications In vehicles, the 10PK belts (often referred to as serpentine belts) facilitate the power transmission from the engine to components like the alternator, power steering pump, and air conditioning compressor. The multi-ribbed design ensures a smooth operation, leading to improved fuel efficiency and lower emissions.

2. Manufacturing In manufacturing plants, 10PK and PK belts are utilized in conveyor systems and other machinery that require continuous movement and power transfer. Their robust construction and durability make them ideal for environments where heavy loads are common.

10pk belt \/pk belt

3. Agriculture In agricultural machinery, such as tractors and harvesters, PK belts help in efficiently transferring power needed for various functions, enhancing productivity and reducing operational costs.

Advantages of 10PK and PK Belts

One of the most compelling reasons for adopting 10PK and PK belts in industrial applications is their numerous advantages

- High Efficiency The design of 10PK belts enhances the grip on pulleys, leading to reduced slippage and power loss. This efficiency allows machines to operate at optimal performance levels.

- Durability Made from quality materials, these belts are engineered to withstand harsh environments and heavy use. Their resistance to wear and tear ensures a longer lifespan, reducing the need for frequent replacements and maintenance.

- Low Noise Operation The construction of the 10PK and PK belts enables quieter operation, a critical factor in applications where noise levels must be kept to a minimum.

- Flexibility Their design allows for flexibility in installation and operation, adapting to various pulleys and machinery configurations.

Conclusion

The significance of 10PK and PK belts in industrial applications cannot be overstated. Their combination of efficiency, durability, and versatility makes them a preferred choice for various sectors, from automotive to agriculture. As technology continues to advance, the materials and designs of these belts are likely to improve further, enhancing their performance and expanding their applications. For industries aiming to streamline operations and improve machinery performance, investing in high-quality 10PK and PK belts is undoubtedly a step in the right direction. Whether you are in manufacturing, automotive, or agriculture, considering the right type of belt can lead to significant operational improvements and cost savings.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025