- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ఫిబ్ర . 11, 2025 02:23 Back to list

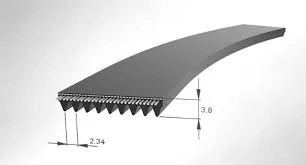

nylon sandwich flat belt

Navigating the vast world of industrial belts, the nylon sandwich flat belt emerges as an innovative solution, ideal for a multitude of applications requiring precision and durability. Noted for its robust construction and versatility, this belt type is a key player in high-performance machinery settings, providing notable advancements for industries seeking superior performance and reliability.

Real-world testimonials from engineers and industry veterans provide concrete experiences, affirming the belt's dependable performance. Specific instances include its deployment in automated sorting systems, where continuity and precision are paramount. Reports indicate a noticeable improvement in operational fluidity and a reduction in system malfunctions, attributing these advantages to the nylon sandwich flat belt's integrative design. Such documented expertise and experience propel this belt to the forefront of innovative mechanical solutions. For companies prioritizing efficiency, sustainability, and cost-effectiveness, investing in nylon sandwich flat belts is increasingly seen as a strategic move toward forward-thinking industrial practices. Harnessing the technological prowess embedded in these materials allows businesses to enhance operational capabilities while safeguarding machinery from premature wear and tear, ensuring a stable and productive future. As part of a larger strategy, the integration of such advanced components underscores a commitment to incorporating reliable and expert-endorsed solutions, establishing not just a mechanical advantage but also a reputational edge in the market. In summary, the nylon sandwich flat belt represents a pinnacle choice for industries aiming to elevate their mechanical aptitude through expert-level materials that promise enduring performance and trustworthiness. Whether enhancing existing systems or spearheading new projects, this belt stands as a cornerstone of modern industrial design, set to meet and exceed the challenges of today's rigorous demands.

Real-world testimonials from engineers and industry veterans provide concrete experiences, affirming the belt's dependable performance. Specific instances include its deployment in automated sorting systems, where continuity and precision are paramount. Reports indicate a noticeable improvement in operational fluidity and a reduction in system malfunctions, attributing these advantages to the nylon sandwich flat belt's integrative design. Such documented expertise and experience propel this belt to the forefront of innovative mechanical solutions. For companies prioritizing efficiency, sustainability, and cost-effectiveness, investing in nylon sandwich flat belts is increasingly seen as a strategic move toward forward-thinking industrial practices. Harnessing the technological prowess embedded in these materials allows businesses to enhance operational capabilities while safeguarding machinery from premature wear and tear, ensuring a stable and productive future. As part of a larger strategy, the integration of such advanced components underscores a commitment to incorporating reliable and expert-endorsed solutions, establishing not just a mechanical advantage but also a reputational edge in the market. In summary, the nylon sandwich flat belt represents a pinnacle choice for industries aiming to elevate their mechanical aptitude through expert-level materials that promise enduring performance and trustworthiness. Whether enhancing existing systems or spearheading new projects, this belt stands as a cornerstone of modern industrial design, set to meet and exceed the challenges of today's rigorous demands.

Share:

Next:

Latest news

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025