- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

நவ் . 16, 2024 14:06 Back to list

v ribbed belts 3288724

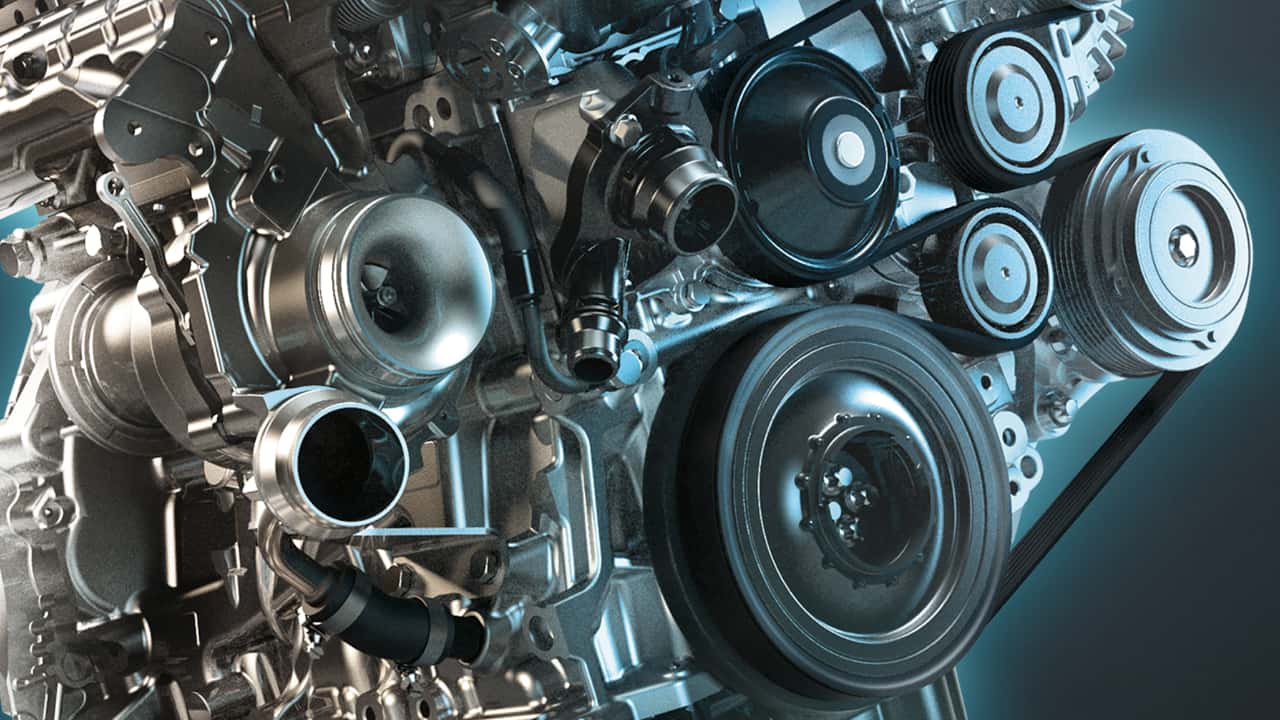

Understanding V Ribbed Belts A Comprehensive Overview

V ribbed belts are integral components in various mechanical systems, playing a crucial role in the operation of engines, machines, and various equipment. Their design and functionality make them favored choices in many industries, ranging from automotive to manufacturing. In this article, we will delve deeper into the characteristics, advantages, and applications of V ribbed belts, with a particular focus on the model designated as 3288724.

What Are V Ribbed Belts?

V ribbed belts, commonly referred to as serpentine belts, are a type of belt with ribbed grooves running along their length. These ribs fit into matching grooves on pulleys, allowing for efficient power transmission. The design of the V ribbed belts enhances grip and ensures that the belt remains firmly in place during operation, reducing the risk of slippage—a common problem with traditional flat belts.

Construction and Materials

The construction of V ribbed belts typically involves a blend of durable materials such as rubber, polyester, and sometimes, reinforced fabrics. These materials are chosen for their strength, flexibility, and resistance to wear. The rubber used is often treated to withstand abrasion, heat, and environmental factors like oil and dust, ensuring longevity. Many modern belts include synthetic materials that provide additional benefits, such as enhanced heat resistance and reduced stretch.

Advantages of V Ribbed Belts

1. High Efficiency Due to their design, V ribbed belts can transmit power more efficiently than flat belts. The ribbed design allows for higher friction between the belt and pulleys, reducing the chances of slippage while maximizing the transmission of power.

2. Compact Design The ability to run multiple peripheral devices with a single belt makes V ribbed belts ideal for space-constrained applications. This eliminates the need for multiple belts and reduces weight, improving overall efficiency in vehicle and machine design.

3. Reduced Noise V ribbed belts often operate more quietly than other belt types, such as chain drives. This makes them suitable for applications where noise reduction is essential, such as in passenger vehicles and office equipment.

4. Versatility These belts are versatile and can be used in various systems. From automobiles to factory machines, their adaptability to different environments makes them a popular choice.

v ribbed belts 3288724

5. Cost-Effectiveness While the initial cost may be slightly higher than traditional belts, the longevity and reduced maintenance requirements lead to lower lifetime costs.

Applications of V Ribbed Belts

V ribbed belts are widely used in several applications

- Automotive Industry In cars, these belts are pivotal for driving the alternator, water pump, power steering pump, and air conditioning compressor. The 3288724 model is designed to meet specific OEM standards, ensuring compatibility with various vehicle models.

- Industrial Equipment Many manufacturing machines utilize V ribbed belts for power transmission, ensuring smooth operation and efficiency.

- HVAC Systems In heating, ventilation, and air conditioning systems, V ribbed belts help drive fans and compressors.

Maintenance and Replacement

While V ribbed belts are robust, regular maintenance checks are necessary to ensure their longevity. Operators should inspect belts for signs of wear, such as cracking or fraying. Belts should also be checked for proper tension; if too loose, they may slip, while excessive tension can lead to premature wear of both the belt and the pulleys.

Replacement of the V ribbed belt should be done according to the manufacturer's recommendations, which is generally after a specific mileage or time interval. For the 3288724 model, referencing the vehicle's service manual can provide specific guidance on replacement timelines.

Conclusion

V ribbed belts, including the 3288724, are vital components in modern mechanical systems. With their efficient design, durability, and wide range of applications, they play a crucial role in power transmission across various fields. Regular maintenance and timely replacement are essential to ensure optimal performance and extend the life of these belts, providing users with the reliability they need in their operations. Understanding the characteristics and applications of V ribbed belts is essential for anyone involved in maintenance, manufacturing, or automotive industries.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025