- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

செப் . 19, 2024 16:56 Back to list

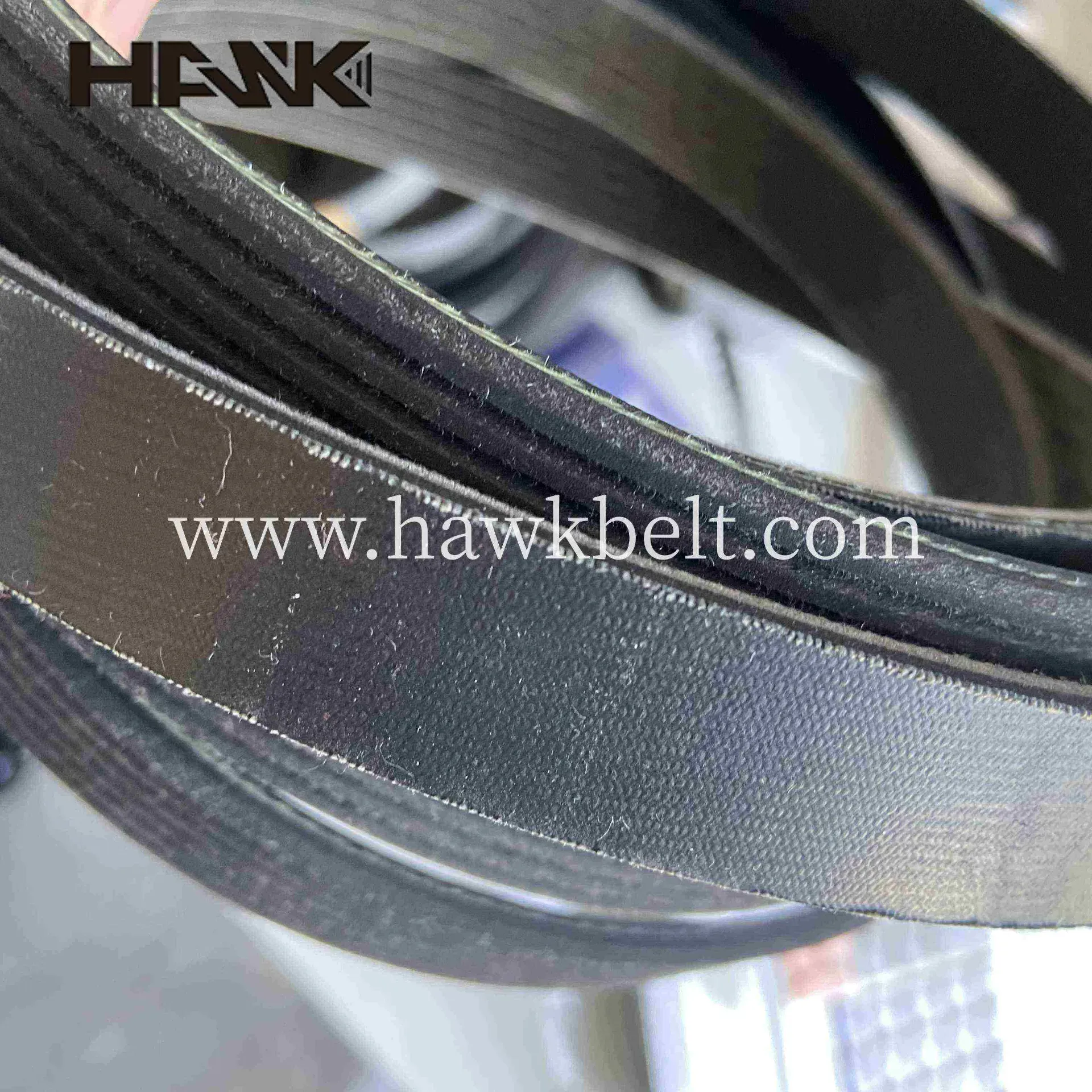

flat belt and v belt

Understanding Flat Belts and V Belts in Mechanical Systems

Belts are integral components in mechanical systems, serving the primary function of transmitting power between driving and driven shafts. Among the various types of belts, flat belts and V belts are the most commonly used. Each type has unique characteristics, advantages, and applications that make them suitable for specific mechanical tasks.

Flat Belts

Flat belts are wide and flat, designed to run over pulleys without the need for grooves. They were commonly employed in older machinery, such as factories and mills, where a centralized power source powered multiple machines through a series of flat belts. One of the significant advantages of flat belts is their ability to operate over longer distances. They can be used in setups where the distance between the drive and driven pulleys is considerable.

However, flat belts do have their drawbacks. They can slip more easily than V belts, particularly under heavy loads or when misaligned. To mitigate slippage, flat belts often require proper tensioning mechanisms. When properly maintained, flat belts can exhibit good flexibility and can accommodate various pulley sizes. Due to their surface friction, they can be efficient in transmitting power without excessive wear when correctly aligned.

flat belt and v belt

V Belts

On the other hand, V belts are characterized by their trapezoidal cross-section. This shape allows them to wedge into the grooves of the pulleys, enhancing friction and reducing slippage. V belts are widely preferred in many modern mechanical systems due to their efficiency and reliability. They provide better power transmission capabilities compared to flat belts, especially in applications that require high torque.

Another advantage of V belts is their compact design, which allows for more efficient space utilization in machinery setups. They are also less susceptible to issues related to alignment, making them a practical choice for many applications in automotive engines, HVAC systems, and industrial machinery.

Conclusion

In summary, the choice between flat belts and V belts largely depends on the specific requirements of the application at hand. Flat belts are beneficial for long-distance power transmission and older equipment, while V belts excel in high-torque and compact environments. Understanding the unique features and applications of each belt type enables engineers and technicians to select the most suitable option for efficient and reliable machinery operation. Whether for historical machinery or cutting-edge technology, both flat belts and V belts remain essential components in the world of mechanical engineering.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025