- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oktoba . 10, 2024 21:12 Back to list

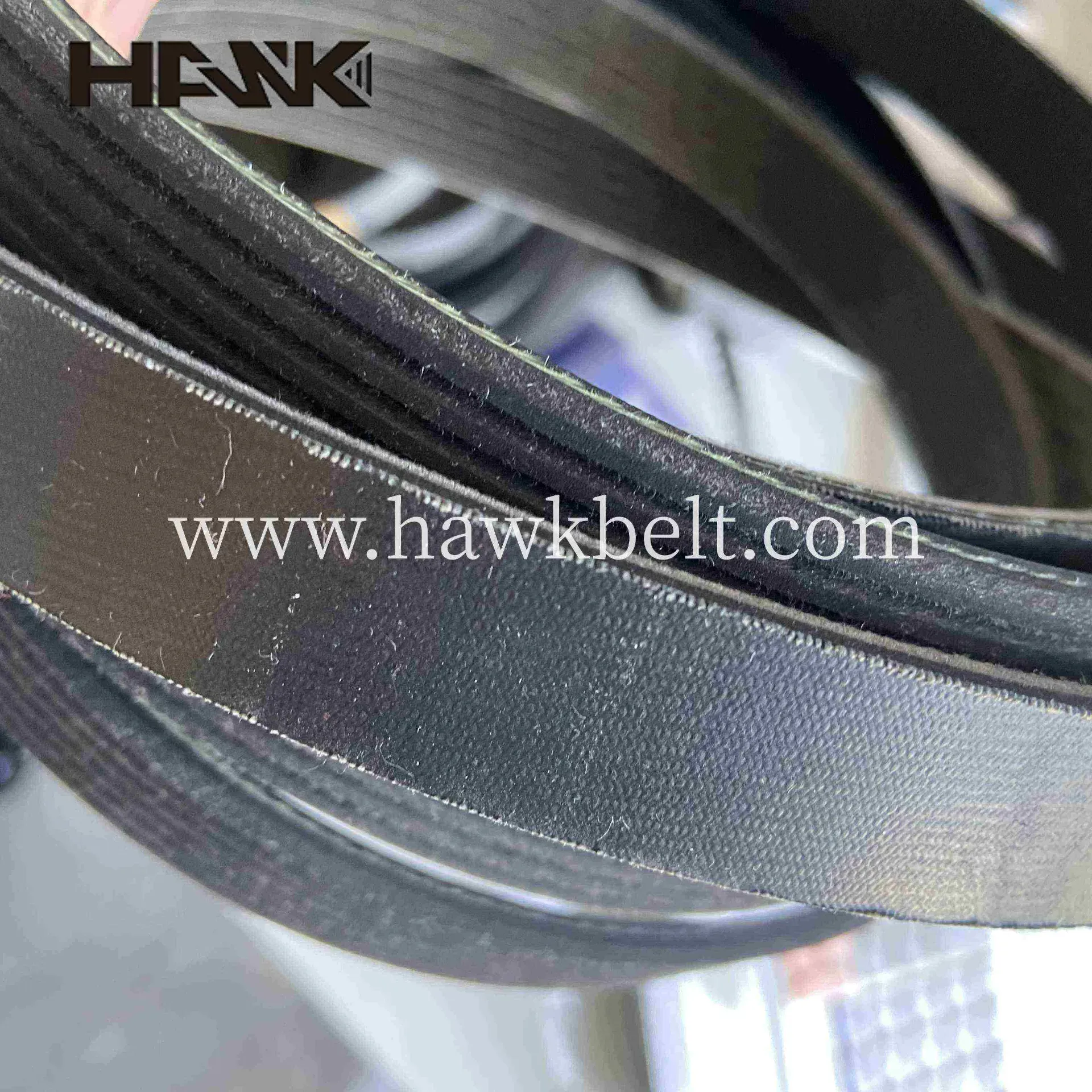

v belt for motor

Understanding V-Belts for Motors A Comprehensive Guide

When it comes to power transmission in mechanical systems, v-belts play a crucial role, particularly in electric motor applications. These versatile components serve as the connective link between the motor and various driven equipment, such as pumps, fans, and compressors. This article delves into the features, advantages, types, and maintenance practices associated with v-belts, helping you understand their importance in motor-driven operations.

What is a V-Belt?

A v-belt, named for its distinctive 'V' shape in cross-section, is a type of flexible coupling designed to transmit power between pulleys. The design of the v-belt allows it to fit snugly into pulley grooves, maximizing friction and minimizing slippage, which enhances efficiency in power transfer. V-belts are made from durable materials, such as rubber, and often reinforced with fibers to withstand varying operational conditions.

Advantages of Using V-Belts

1. Efficiency V-belts provide excellent power transmission efficiency, often exceeding 90%. Their design prevents slippage, meaning that they can maintain consistent contact with the pulleys.

2. Flexibility These belts can easily adapt to different operating conditions, making them suitable for a wide range of applications. They can accommodate small pulley diameters effectively, unlike flat belts.

3. Reduced Noise and Vibration The construction of v-belts minimizes noise and vibration, which contributes to quieter operation in motors.

4. Cost-Effectiveness V-belts are generally more affordable than other power transmission components, such as chains or gears, providing a cost-effective solution for many applications.

5. Simple Installation and Maintenance Installing and adjusting v-belts is straightforward, allowing for easy maintenance and replacement when necessary.

Types of V-Belts

V-belts can be classified into several types based on their structure and intended use. The most common types include

1. Classic V-Belts These are the standard design and are commonly used in various applications. They come in different sizes to fit various pulleys.

v belt for motor

2. Narrow V-Belts These belts have a smaller cross-section and are designed for high-speed applications where space is limited. They offer increased performance capabilities but require precise alignment to avoid slip.

3. Wrapped V-Belts Feature an outer wrapping of fabric that increases durability and resistance to wear. They are ideal for heavy-duty applications.

4. Cogged V-Belts These belts have notches along their length, which improve flexibility and reduce bending resistance. This design also allows for better heat dissipation.

5. High-Performance V-Belts Made from advanced materials and designed for high-efficiency applications, these belts can handle extreme loads and environmental conditions.

Maintenance Practices for V-Belts

To ensure optimal performance and longevity of v-belts, maintenance is essential. Here are some best practices

1. Regular Inspections Periodically check the belts for signs of wear, such as cracks, fraying, or glazing. Regular inspections can help identify issues before they lead to failure.

2. Proper Tensioning Ensure that v-belts are properly tensioned. Overly tight belts can cause excessive wear on both the belt and the motor bearings, while loose belts may slip and reduce efficiency.

3. Alignment Make sure the pulleys are aligned correctly. Misalignment can cause uneven wear and reduce the lifespan of the belt.

4. Cleaning Keep the belts and pulleys clean from debris and contaminants that can lead to slipping or damage.

5. Temperature Monitoring V-belts can be affected by extreme temperatures. Monitor the operating conditions and replace belts that show signs of deterioration due to heat.

Conclusion

V-belts are integral components in motor-driven applications, providing an effective means of power transmission. Their efficiency, flexibility, and cost-effectiveness make them a popular choice across various industries. Understanding the different types of v-belts and maintaining them properly can enhance performance and extend their lifespan, ensuring reliable operation in your machinery. Whether you’re a technician, engineer, or a DIY enthusiast, grasping the fundamental aspects of v-belts will empower you to make informed decisions regarding their usage and upkeep in your motor applications.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025