- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Novemba . 30, 2024 13:28 Back to list

v belt 5kw

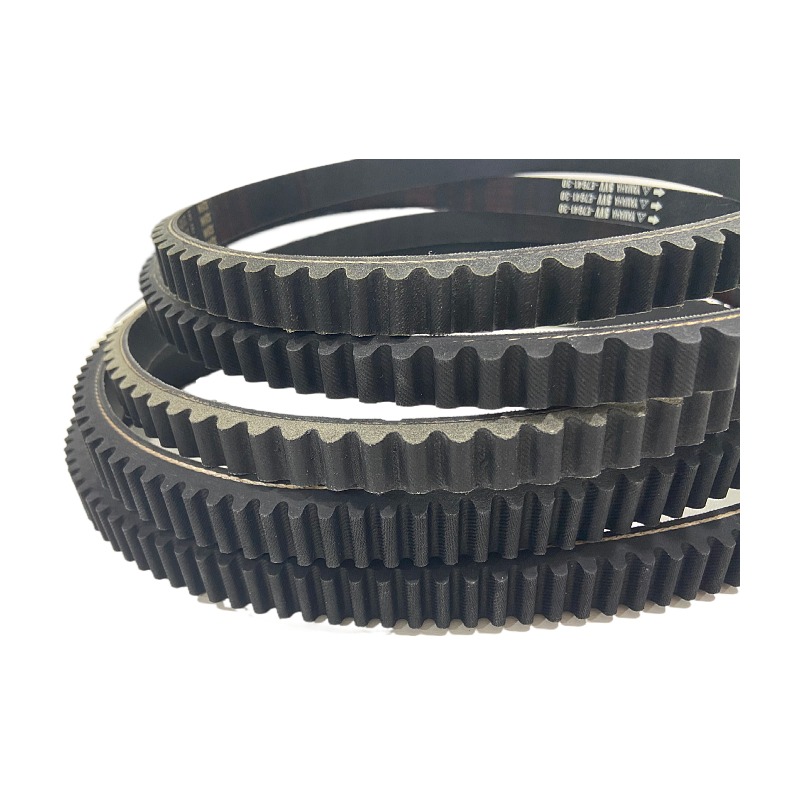

Understanding V-Belts The Key to Efficient Power Transmission in 5kW Applications

V-belts are a crucial component in various mechanical systems, serving as a vital link in transmitting power from one component to another. Particularly in applications involving motors with a power output of around 5kW, V-belts play an essential role in ensuring efficiency, reliability, and performance. In this article, we will explore what V-belts are, their advantages, their applications, and tips for choosing the right V-belt for your needs.

What is a V-Belt?

A V-belt is a type of flexible belt that has a trapezoidal cross-section, which allows it to fit snugly into grooves on pulleys. This design helps to increase the contact area between the belt and the pulley, ensuring effective power transmission. V-belts are commonly made from rubber or synthetic materials and may have fabric or wire reinforcements to enhance their strength and durability.

Advantages of V-Belts

1. High Efficiency One of the primary benefits of V-belts is their high efficiency in power transmission. The design minimizes slippage, allowing them to maintain a firm grip on the pulleys, which is crucial for applications requiring smooth operation.

2. Flexibility and Versatility V-belts can be used in various setups, making them suitable for different types of machinery, including pumps, compressors, and conveyors. This versatility is particularly beneficial for industries that utilize 5kW motors in their operations.

3. Cost-Effective Compared to other power transmission methods like chain drives or gears, V-belts are generally more affordable to manufacture and maintain. The simplicity of their design contributes to lower production costs, making them a cost-effective choice for businesses.

4. Ease of Installation and Maintenance Installing a V-belt system is relatively straightforward, and maintenance usually involves only periodic checking for wear and tension adjustments. This ease of use is a significant advantage for operators looking to minimize downtime.

5. Low Noise Levels V-belts operate more quietly than other drive systems, contributing to a quieter working environment. This characteristic is particularly appreciated in applications where noise reduction is essential.

Applications of V-Belts in 5kW Systems

In systems powered by 5kW motors, V-belts find widespread application across various industries. Some common uses include

- Agricultural Equipment V-belts are used in tractors and other machinery to drive components such as grinders or harvesters efficiently.

v belt 5kw

- HVAC Systems V-belts facilitate the operation of fans and blowers in heating, ventilation, and air conditioning systems, contributing to optimal climate control.

- Conveyor Systems In manufacturing and logistics, V-belts are crucial for driving conveyor belts, ensuring materials are moved smoothly through different stages of production.

- Automotive Applications V-belts are integral to the functioning of various automotive components, including alternators and water pumps, enhancing overall efficiency.

Selecting the Right V-Belt

When choosing a V-belt for a 5kW system, several factors should be considered

1. Belt Size Ensure that the V-belt matches the size and geometry of the pulleys in your system.

2. Material Select belts made from durable materials that can withstand the operational environment, including temperature fluctuations and exposure to harsh substances.

3. Type of V-Belt Different V-belt types, such as classical, narrow, or wrapped designs, may be more suitable depending on the specific application and requirements.

4. Tension Requirements Proper tension is critical for optimal performance. Refer to the manufacturer's guidelines to ensure correct installation.

5. Brand Reputation Choose reliable brands with a proven track record in performance and durability, which can provide peace of mind and reduce long-term maintenance costs.

Conclusion

V-belts play an indispensable role in the power transmission of 5kW systems across various applications. Their efficiency, versatility, and ease of maintenance make them an ideal choice in many mechanical setups. By understanding the benefits and selecting the right type for your needs, you can ensure that your systems operate smoothly and effectively.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025