- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oktoba . 18, 2024 17:47 Back to list

Comparison of Fan Belts and Ribbed V Belts for Optimal Performance

Understanding the Differences Between Fan Belts and Ribbed V Belts

When it comes to automotive engines and machinery, various components work together to ensure smooth operation. Among these components, fan belts and ribbed V belts play essential roles in transferring power and supporting various functions. While they may seem similar, understanding the differences between fan belts and ribbed V belts can help you make informed decisions about maintenance and replacements.

What is a Fan Belt?

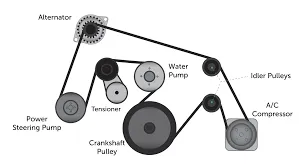

A fan belt, typically referred to as a serpentine belt, is a type of drive belt used in many modern vehicles. Its primary function is to drive the engine's cooling fan, but it also powers other components such as the alternator, power steering pump, water pump, and air conditioning compressor. The fan belt is named for its ability to move air to cool the engine and its associated parts.

Fan belts are often made from durable materials like rubber, and many now have a specialized design that includes grooves or ribs along their length. These grooves enhance the belt's grip, allowing it to maintain better contact with the pulleys it drives, thus preventing slippage. The serpentine design also allows a single belt to connect multiple accessories, resulting in a more efficient and compact system.

What is a Ribbed V Belt?

On the other hand, the ribbed V belt, commonly known as a V belt, is a traditional drive belt featuring a V-shaped cross-section. Ribbed V belts have grooves on one side that fit into matching pulleys, providing traction needed to drive various engine components. Unlike serpentine belts, which are often wider and can drive multiple components, ribbed V belts typically connect to individual accessories and are used in older vehicles or specific machinery.

Ribbed V belts are known for their robustness and effectiveness in transferring power. However, they require more space and maintenance, as multiple belts may be needed to drive the same components often powered by a single serpentine belt in newer designs.

fan belt\/ribbed v belt

Key Differences

1. Design The most notable difference between fan belts and ribbed V belts is their design. Fan belts are typically wider, featuring ribs that aid in grip, while ribbed V belts have a distinct V shape and are generally narrower.

2. Functionality A fan belt can drive multiple accessories simultaneously, making it efficient for modern engines. In contrast, ribbed V belts may operate individual accessories, often resulting in a more complex setup requiring more space.

3. Maintenance Serpentine belts generally require less maintenance since they tend to wear evenly and have a longer lifespan. Ribbed V belts, on the other hand, may need regular inspection and replacement due to wear on individual belts.

4. Applications Fan belts are widely used in modern vehicles, while ribbed V belts are still found in older models and specific machinery that may not utilize serpentine systems.

Conclusion

In conclusion, both fan belts and ribbed V belts are crucial for the operation of vehicles and machinery. Understanding their differences can enhance maintenance practices and ensure optimal performance. As technology advances, fan belts have become more popular due to their efficiency and versatility. However, ribbed V belts still serve a purpose in various applications, highlighting the diverse engineering solutions tailored to specific automotive needs. Whether you maintain older machinery or modern vehicles, recognizing the role of these belts will lead to better care and longevity of your equipment.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025