- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Desemba . 15, 2024 19:16 Back to list

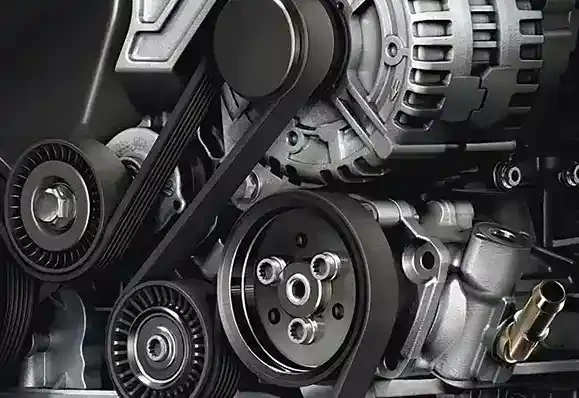

engine belt drive

Understanding Engine Belt Drives Mechanics and Applications

Engine belt drives are an essential component in various mechanical systems, playing a crucial role in the transmission of power between different machinery components. Their simplicity, reliability, and effectiveness make them a preferred choice in automotive engines, industrial machines, and even household appliances. In this article, we will explore the mechanics behind engine belt drives, their types, applications, and the advantages they offer.

Mechanics of Belt Drives

At its core, a belt drive consists of a belt, typically made of rubber or another flexible material, which connects two or more pulleys. When one pulley, known as the driver pulley, is rotated by an engine or motor, the motion is transferred to the connected driven pulley via the belt. This transfer of rotational motion allows the drive system to operate various components, such as alternators, water pumps, or fans, depending on the application.

The efficiency of a belt drive depends on several factors, including the type of belt used, its tension, and the groove design of the pulleys. The belt must be appropriately tensioned to prevent slippage while minimizing wear and tear. Over time, belts can stretch, leading to the need for periodic adjustment or replacement.

Types of Belt Drives

Belt drives come in different types, each designed to suit specific applications. The most common types include

1. V-belts These are wedge-shaped belts that fit into V-shaped grooves on pulleys. They provide a high friction grip, allowing for efficient power transmission. V-belts are commonly used in automotive systems and various industrial applications due to their durability.

2. Flat belts Unlike V-belts, flat belts are rectangular and operate on flat pulleys. They are often used in older machinery and can transmit power over longer distances without much slippage.

3. Timing belts These belts have teeth that interlock with corresponding grooves on pulleys, ensuring precise timing and synchronization. Timing belts are critical in engines for maintaining the synchronization between the crankshaft and camshaft.

engine belt drive

4. Toothed belts Similar to timing belts, these belts feature teeth but are often used in conveyor systems or automated machinery where precise positioning is required.

Applications of Engine Belt Drives

Engine belt drives find applications across various fields. In the automotive industry, they are essential for connecting the engine to various components. For instance, the serpentine belt, a type of V-belt, drives multiple accessories like the alternator, power steering pump, air conditioning compressor, and more. This design allows for a more compact engine setup and reduces the overall weight of the vehicle.

In industrial settings, belt drives are used to transfer power from motors to machinery such as conveyor belts, fans, and pumps. Their ability to handle different loads and configurations makes them versatile for various manufacturing and processing operations.

Belt drives are also common in household appliances. Washing machines, dryers, and lawnmowers utilize belt drives to convert motor power into the necessary mechanical motion. The reliability of belt drives in these applications ensures longevity and minimal maintenance.

Advantages of Engine Belt Drives

One of the primary advantages of engine belt drives is their smooth and quiet operation. They can absorb shocks and reduce vibrations, contributing to a more pleasant user experience. Additionally, belt drives are relatively easy to install and maintain, requiring minimal tools and expertise.

Furthermore, they provide flexibility in design. Because belts can be routed around corners and through tight spaces, engineers can create more compact machinery designs without sacrificing performance.

In conclusion, engine belt drives are integral to many mechanical systems, offering efficiency, reliability, and versatility across different applications. Whether in automotive engines, industrial machinery, or household appliances, understanding how belt drives work and their advantages can lead to better design choices and maintenance strategies. As technology advances, we can expect further innovations in belt drive systems, enhancing their performance and applicability in various sectors.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025