- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Agosti . 04, 2025 04:20 Back to list

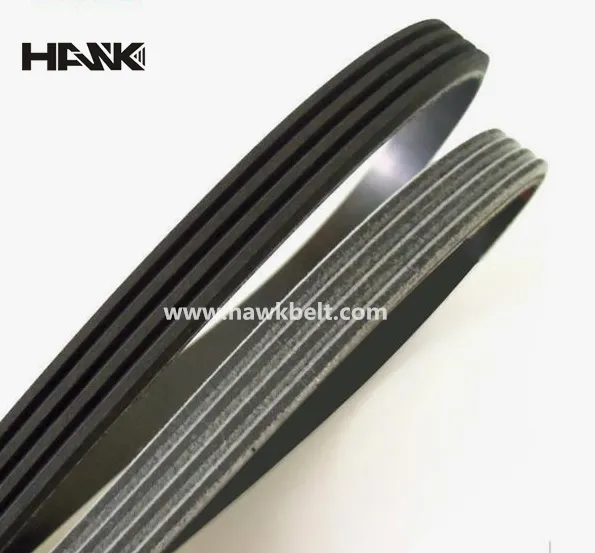

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

Keywords: diesel engine belt, tensioner fan belt, tensioner belt pulley, engine accessory drive belt, emergency serpentine belt

Industry Overview & Trends: The Evolving World of Diesel Engine Belt Technology

Diesel engines are integral to a wide array of heavy-duty applications, from construction to logistics. The diesel engine belt is a critical component within the accessory drive system, responsible for transmitting power to ancillary equipment such as alternators, water pumps, air conditioning compressors, and hydraulic pumps.

Latest Industry Insights (2023): According to Global Market Insights, the automotive belt market is projected to reach USD 11.9 billion by 2032, with the diesel engine belt segment accounting for over 36% of the demand due to increased heavy machinery production and stricter emission regulations ([source](https://www.gminsights.com/industry-analysis/automotive-timing-belt-market)).

Latest Industry Insights (2023): According to Global Market Insights, the automotive belt market is projected to reach USD 11.9 billion by 2032, with the diesel engine belt segment accounting for over 36% of the demand due to increased heavy machinery production and stricter emission regulations ([source](https://www.gminsights.com/industry-analysis/automotive-timing-belt-market)).

Key Terminologies Explained

- Diesel Engine Belt: Multi-ribbed or serpentine belt powering accessories in diesel engines.

- Tensioner Fan Belt: Maintains adequate tension, preventing slippage or misalignment.

- Tensioner Belt Pulley: Provides smooth rotation and maintains belt track alignment.

- Engine Accessory Drive Belt: Transfers mechanical energy to alternators, AC, pumps, etc.

- Emergency Serpentine Belt: Designed as a quick-repair solution for unexpected failures.

Application Scenarios: Demanding Environments for Diesel Engine Belt

Diesel engine belt systems are essential across multiple heavy industries:

- Construction Machinery (MAN, IVECO, VOLVO Excavators, Loaders, etc.)

- Petrochemical Plants & Power Generators

- Mining & Metallurgical Equipment

- Water Treatment Facilities (Pump Drives)

- Large Transport Vehicles & Marine Engines

Case Highlight: A 2023 report from Volvo Construction noted a 12% decrease in engine downtime after switching to advanced reinforced diesel engine belt systems.

Technical Data & Parameter Visualization

General Diesel Engine Belt Specifications

| Specification | Standard Range | Relevance |

|---|---|---|

| Material | EPDM, HNBR, CR, Reinforced Fiber | Chemical, Heat & Wear Resistance |

| Number of Ribs | 4PK, 6PK, 8PK, 10PK | Power Transmission Capacity |

| Width | 7–40 mm | Application Matching |

| Tensile Strength | ≥2000N/cm | Load Endurance |

| Service Life | 60,000–120,000 km (or 4–7 years) | Long-Term Reliability |

| Operating Temp. | -35°C to +120°C | Wide Environment Adaptability |

| Certifications | ISO 9001:2015, TUV, ANSI/SAE J1459 | International Standard Compliance |

Material Usage Distribution in Diesel Engine Belts (2023)

Spotlight Product: Heavy V-Ribbed Belt VOE979064 8PK for MAN, IVECO, VOLVO

Product Name: Heavy V-Ribbed Belt VOE979064 8PK

Designed for exceptional reliability in rigorous construction equipment environments, VOE979064 8PK delivers superior performance for MAN, IVECO, and VOLVO machines.

Available Directly: Product Page

Designed for exceptional reliability in rigorous construction equipment environments, VOE979064 8PK delivers superior performance for MAN, IVECO, and VOLVO machines.

Available Directly: Product Page

| Parameter | VOE979064 8PK | OEM Reference |

|---|---|---|

| Number of Ribs | 8PK | 6PK–10PK (varied) |

| Length | 1495 mm | 900–2300 mm |

| Width | 29 mm | 17–39 mm |

| Material | Eco-EPDM + Polyester Cord/Aramid Fiber | CR/HNBR/Polyester |

| Tensile Strength | 2550 N/cm | 1800–2200 N/cm |

| ISO/ANSI Standard | ISO 9011, ANSI/SAE J1459 | Varied (not always certified) |

| Operating Temperature | -35°C to +120°C | -25°C to +110°C |

| Expected Lifespan | 7 Years / 120,000 km | 4 Years / 90,000 km |

| Special Features | Anti-static, Oil-resistant, Whisper-Quiet | Standard |

Performance Comparison: VOE979064 8PK vs. Conventional Diesel Engine Belts

Belt Longevity: Years of Service for Common Diesel Engine Belts

Manufacturing Process: Advanced Workflow of Diesel Engine Belt Production

Manufacturing diesel engine belt like the VOE979064 8PK involves precision processes driven by stringent international standards and advanced materials. Below is a visual overview:

Key Stages (with explanations):

Raw Material Selection (EPDM, HNBR, Aramid) → Compound Mixing (evenly blending polymers) → Extrusion (shape formation) → CNC Rib Cutting (precision rib geometry) → Vulcanization (cross-linking for durability) → QC (tensile/fatigue tests, ISO 9011 compliance).

Raw Material Selection (EPDM, HNBR, Aramid) → Compound Mixing (evenly blending polymers) → Extrusion (shape formation) → CNC Rib Cutting (precision rib geometry) → Vulcanization (cross-linking for durability) → QC (tensile/fatigue tests, ISO 9011 compliance).

Manufacturing Advantages:

- Use of specialty polymers (e.g., high-durability Eco-EPDM)

- Robust CNC rib profiling for ultrasmooth engagement

- Automated tension & fatigue testing under ISO 9011/ANSI/SAE J1459 standards

- Corrosion-resistant and anti-static treatment

- Environmentally controlled vulcanization ensuring uniformity

Industry Leader Comparison: VOE979064 8PK vs. Competitor Belts

| Brand/Model | Material | Tensile Strength | Certifications | Anticorrosion | Warranty |

|---|---|---|---|---|---|

| HawkBelt VOE979064 8PK | Eco-EPDM + Aramid | 2550 N/cm | ISO 9011, SAE J1459 | Yes | 24 months |

| ContiTech 8PK1883 | HNBR | 2100 N/cm | ISO 9001 | Yes | 18 months |

| Gates Micro-V 8PK | SBR + Fiber | 2050 N/cm | ISO 9001 | Limited | 12 months |

| Generic OEM 8PK | CR/Polyester | 1850 N/cm | None | No | 6 months |

Customization & Engineering Solutions

Custom diesel engine belt projects are available for complex machinery and unusual drive geometries. Specifications can be adjusted in:

- Rib count (PK), profile angle, custom lengths

- Material compositions: Polyester/Aramid/CR/HNBR/EPDM

- High flexibility or enhanced heat-resistance for atypical operating environments

- Color coding, printed labeling for easy asset management

Application Case Study: Mining Industry Success

Customer: - A West Africa gold mining operation running 24/7 in abrasive, dusty environments.

Challenge: - Conventional belts suffered rapid fatigue, with average failure at 45,000 km.

Solution: - Upgrading to Heavy V-Ribbed Belt VOE979064 8PK increased average lifespan to 112,000 km, substantially reduced maintenance intervals, and improved operational uptime by 18%.

Feedback: - “After switching, our equipment runs cooler and quieter. Unplanned stoppages are down to near zero.” – Maintenance Supervisor, JND Mining Ltd.

Challenge: - Conventional belts suffered rapid fatigue, with average failure at 45,000 km.

Solution: - Upgrading to Heavy V-Ribbed Belt VOE979064 8PK increased average lifespan to 112,000 km, substantially reduced maintenance intervals, and improved operational uptime by 18%.

Feedback: - “After switching, our equipment runs cooler and quieter. Unplanned stoppages are down to near zero.” – Maintenance Supervisor, JND Mining Ltd.

Delivery & After-sales: Commitment to Reliability

Delivery Cycle: Standard items ship within 5–7 workdays; custom belts: 15–21 days.

Warranty: 24 months on VOE979064 8PK under normal operation.

Customer Support: 7x24h technical hotline, global service partners.

Certifications: All belts pass ISO 9011 fatigue/flex test and come certified for ANSI/SAE J1459 where applicable.

Warranty: 24 months on VOE979064 8PK under normal operation.

Customer Support: 7x24h technical hotline, global service partners.

Certifications: All belts pass ISO 9011 fatigue/flex test and come certified for ANSI/SAE J1459 where applicable.

Professional FAQ: Technical Questions on Diesel Engine Belt

- 1. What is the primary material used for VOE979064 8PK diesel engine belt?

- It uses Eco-EPDM reinforced with polyester/aramid cord, providing superior heat, wear, and ozone resistance versus ordinary neoprene (CR).

- 2. How is tension maintained in engine accessory drive belt systems?

- With automatic or spring-loaded tensioner belt pulleys to ensure optimal grip, prolong belt life, and suppress noise.

- 3. What relevant international standards apply?

- ISO 9011 (belt structure/durability), ANSI/SAE J1459 (material & performance), plus RoHS/FDA (for certain use-cases).

- 4. How can I select the right length/PK specification?

- Refer to OEM manual; count pulley grooves for PK (“Poly K”) and measure belt path. HawkBelt offers sizing guide consultations.

- 5. What is the typical installation torque or tension for a diesel engine belt?

- Typically, 220–320 N of tension at the midpoint; installation to be done per OEM and ISO/SAE torque tables to avoid premature failure.

- 6. Can belts be used in chemically aggressive environments?

- Yes, Eco-EPDM belts are oil, chemical, and ozone-resistant – suitable for petrochemical/mining but periodic inspection is advised.

- 7. What is an emergency serpentine belt and its use case?

- An emergency serpentine belt is a universal, quick-fit replacement used temporarily in breakdowns; VOE979064 8PK can be custom supplied in such emergency kits.

Diesel Engine Belt Technical Advantage Summary

Heavy V-Ribbed Belt VOE979064 8PK stands out for:

- High efficiency, low slip operation due to advanced rib/cross-section design

- Superior chemical, abrasion & temperature resistance

- Longer lifespan & higher warranty standards than industry norms

- Comprehensive international quality certification (ISO, ANSI/SAE)

- Adaptability to custom requirements for specialized heavy-duty equipment

References & Industry Insights

“Routine maintenance and material upgrades in industrial belts can reduce unexpected breakdowns by over 40%.” – Engineering Tips Forum

"ISO 9011 certified V-ribbed belts have shown up to 28% greater performance retention in petrochemical equipment." – Journal of Materials Processing Technology

Further Reading: SAE J1459 Belt Performance Standard

"ISO 9011 certified V-ribbed belts have shown up to 28% greater performance retention in petrochemical equipment." – Journal of Materials Processing Technology

Further Reading: SAE J1459 Belt Performance Standard

Sources: Global Market Insights, ISO/SAE, Volvo Construction, customer case studies.

For more industry insights: Engineering Tips Forum | ScienceDirect Journal

For more industry insights: Engineering Tips Forum | ScienceDirect Journal

Share:

Next:

This is the last article

Latest news

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025