- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Novemba . 05, 2024 15:05 Back to list

8m-1552-28 pk drive belt

Understanding the 8M-1552-28% Drive Belt

When it comes to machinery and mechanical systems, drive belts play a critical role in transmitting power and ensuring efficient operation. Among the various types of drive belts available, the 8M-1552-28% drive belt stands out due to its unique specifications and applications. In this article, we will delve into the features, advantages, and potential uses of the 8M-1552-28% drive belt, providing a comprehensive overview for engineers, technicians, and hobbyists alike.

Specifications and Features

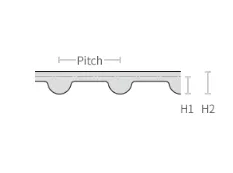

The 8M-1552-28% drive belt is characterized by its unique 8mm pitch size, which is a measure of the distance between the centers of two adjacent teeth on the belt. This specific dimension ensures a well-balanced fit in various mechanical systems, providing reliable power transmission. Additionally, the 1552 in the model number indicates the effective length of the belt, which is 1552 millimeters.

The “28%” in the designation refers to the belt's percentage of critical elongation, indicating its elasticity and ability to maintain effective tension under varying loads. This property is particularly important in applications where the drive belt is subjected to fluctuating stress, ensuring longevity and performance.

Advantages

Understanding the 8M-1552-28% Drive Belt

Moreover, the specific design enables this belt to operate effectively even in high-temperature situations, which is often a concern in industrial settings. This durability greatly reduces the need for frequent replacements, translating to lower maintenance costs and increased operational efficiency.

8m-1552-28 pk drive belt

Applications

The 8M-1552-28% drive belt finds extensive use across various industries. It is particularly beneficial in the manufacturing and automation sectors, where it drives conveyors, motors, and other machinery. The belt’s ability to transmit power effectively without significant energy loss makes it ideal for continuous operations typical in production lines.

In addition to industrial applications, this drive belt is also popular in robotics, where precise motion control is paramount. The belt’s elasticity ensures that it can adapt to the dynamic nature of robotic movements, maintaining accuracy over time.

Another noteworthy application is in the automotive sector, particularly in go-karts and small vehicles where the belt’s lightweight design and effective power transfer can result in enhanced performance.

Conclusion

In summary, the 8M-1552-28% drive belt is an essential component for various mechanical systems across multiple industries. Its unique specifications, such as the 8mm pitch, 1552mm length, and 28% elongation rate, make it a versatile and reliable choice for engineers and technicians seeking optimal performance in their applications.

The advantages it offers, including durability, elasticity, and resistance to wear, further cement its role as a preferred choice in high-performance environments. Understanding its features and potential applications can equip professionals with the knowledge needed to select the right drive belt for their specific needs, ultimately contributing to improved efficiency and cost-effectiveness in their operations.

Whether in manufacturing, robotics, or automotive applications, the 8M-1552-28% drive belt continues to demonstrate its importance in modern engineering, making it a valuable component in the ongoing quest for enhanced mechanical efficiency.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025