- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

jul . 30, 2024 12:41 Back to list

Guide to Understanding and Finding the Right Sizes for 3pk Belt Options

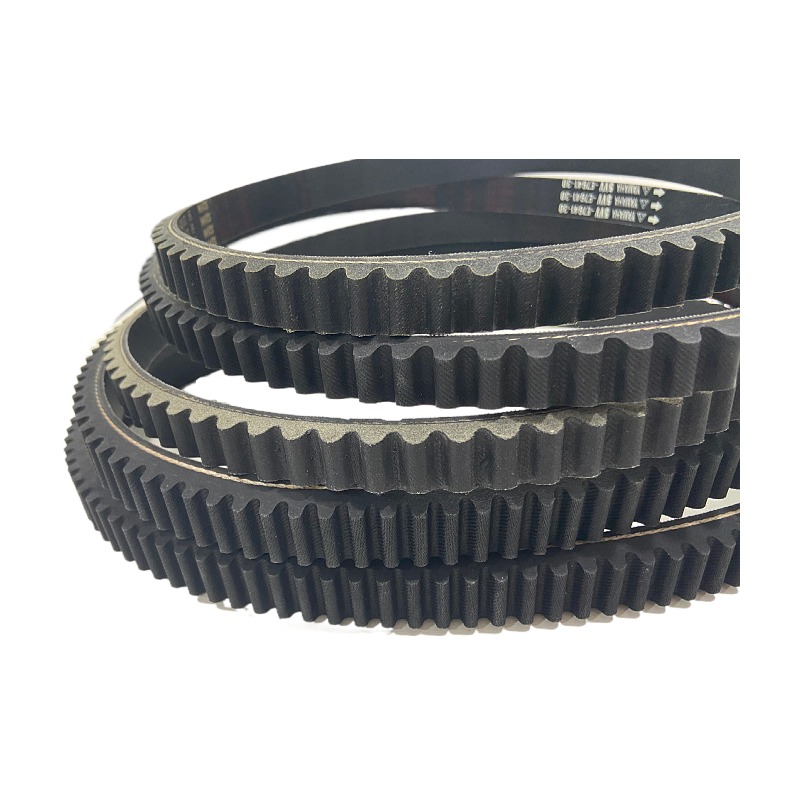

Understanding 3PK Belt Sizes A Comprehensive Guide

When it comes to machinery and automotive applications, the significance of the 3PK belt cannot be overstated. Belts play a crucial role in the smooth functioning of various mechanical systems, and selecting the right size is essential for optimal performance. In this article, we will delve into the specifics of 3PK belt sizes, their characteristics, and how to choose the right one for your needs.

What is a 3PK Belt?

A 3PK belt refers to a specific type of V-belt characterized by three key components — the number '3' indicating the number of ribs the belt has, 'P' standing for the profile design which is generally a narrow V-shape, and 'K' denoting the metric size. These belts are commonly used in a variety of applications, including agricultural equipment, lawnmowers, and various industrial machinery.

Sizes and Specifications

The sizing of 3PK belts typically follows a standardized naming convention that reflects the length and width dimensions of the belt. Generally, the length is measured in millimeters, and the width is standardized, which allows for compatibility across a range of machines and applications.

For instance, a 3PK belt might be labeled as 3PK850, where '850' indicates the belt’s length – in this case, 850 mm. When purchasing a belt, it's important to refer not only to the length but also to the width and the rib count, as these factors influence the belt's performance and fit within your machinery.

Common Applications

3PK belts are widely utilized in various sectors due to their efficiency and reliability. You’ll find them in

1. Automotive Applications In vehicles, 3PK belts can drive multiple systems such as water pumps, alternators, and air conditioning compressors. Proper sizing ensures that all components operate smoothly.

3pk belt sizes

2. Agricultural Equipment Tractors and other farming machinery often rely on these belts for the operation of key systems. Their robustness and durability under heavy load conditions make them ideal for such applications.

3. Industrial Machinery Numerous manufacturing and assembly line machines use 3PK belts to transfer power between components, enhancing productivity and performance.

Choosing the Right 3PK Belt Size

Choosing the correct size of a 3PK belt is vital for ensuring the longevity of your machinery and the efficiency of its operations. Here are some steps to consider

1. Measure the Old Belt If you are replacing an existing belt, measure its length and width to determine the correct size. It’s also important to check any part numbers or specifications indicated on the old belt.

2. Consult Machinery Manuals Refer to the machinery’s user manual, which often provides the exact specifications of the compatible belt sizes.

3. Consider Application Requirements Take into account the specific requirements of your application. Environmental conditions, load requirements, and operational speed all play a role in determining the best belt for your needs.

4. Seek Expert Advice If you’re unsure about the size or type of belt required, don’t hesitate to consult with experts or suppliers who can offer guidance based on your specific machinery and requirements.

Conclusion

Selecting the right 3PK belt size is crucial for maintaining the efficiency and longevity of your machinery. By understanding the specifications, applications, and methods of selection, you can ensure that you choose the appropriate belt to meet your operational needs. Always remember that proper maintenance and timely replacement of belts can prevent costly downtimes and enhance the overall productivity of your equipment.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025