- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 23, 2024 09:08 Back to list

timing belts for sewing machine

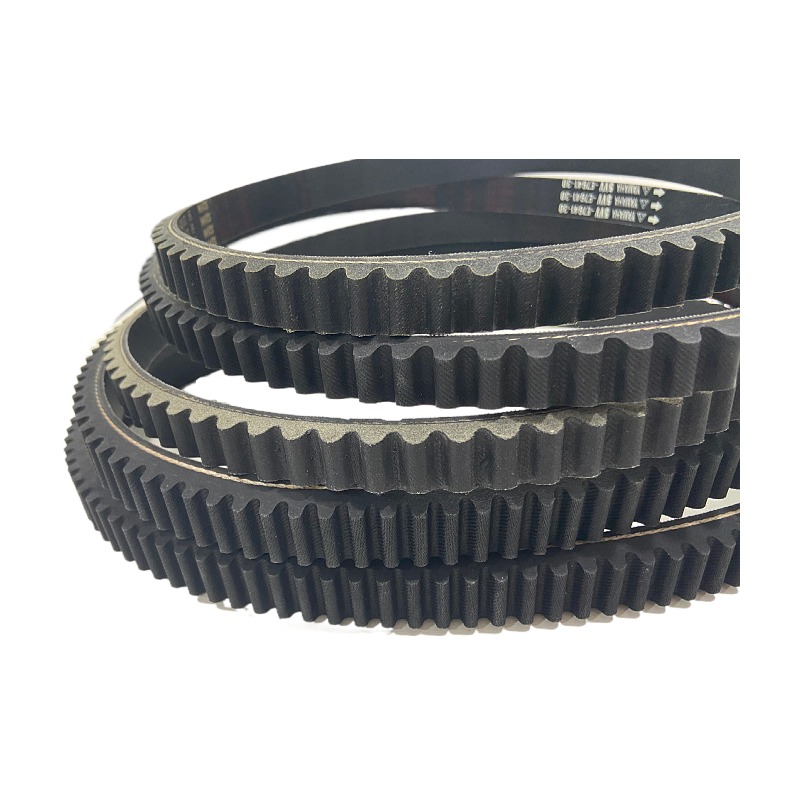

Timing Belts for Sewing Machines Essential Components for Precision

Timing belts play a crucial role in the functionality of sewing machines, ensuring precision and consistency during the sewing process. These belts are designed to synchronize the motion of various components within the machine, allowing for smooth operation and optimal performance. Understanding the importance of timing belts can help sewing enthusiasts and professionals appreciate their role in sewing machine mechanics and maintenance.

What is a Timing Belt?

A timing belt is a rubber or polymer belt with teeth that meshes with gears or pulleys. This design allows the belt to maintain a precise relationship between the driven components, ensuring that they reach their intended positions at the right time. In sewing machines, timing belts help control the movement of the needle, feed dogs, and other essential parts, enabling accurate stitching according to the chosen settings.

Importance of Timing Belts in Sewing Machines

1. Precision in Stitching The primary function of timing belts in sewing machines is to keep the needle and feed mechanisms in sync. This synchronization is vital for producing even stitches, ensuring that each stitch is formed without skipping or misalignment. For professionals working on high-quality garments, the precision provided by timing belts is indispensable.

2. Reduced Wear and Tear A properly functioning timing belt can reduce the wear on other mechanical parts within the sewing machine. By ensuring that components operate in harmony, timing belts minimize friction and strain, leading to a longer lifespan for the machine. Regular maintenance and timely replacement of worn-out belts can help avoid costly repairs down the line.

3. Enhanced Performance In modern sewing machines, especially those with advanced features such as embroidery and automatic stitching, timing belts play an integral role in performance. These machines require precise control over various functions, and reliable timing belts ensure that each action is completed accurately. This reliability is crucial for both home sewers and industrial applications.

timing belts for sewing machine

Signs of Timing Belt Wear

Understanding the signs of timing belt wear can empower users to maintain their sewing machines effectively. Common indicators include

- Unusual Noises If the sewing machine starts making grinding or slapping sounds, it may indicate that the timing belt is worn or misaligned. - Inconsistent Stitch Quality Problems with stitch formation, such as skipped stitches or uneven tension, can be a sign of a failing timing belt. - Difficulty in Motion Stiffness or resistance when operating the machine may also suggest that the timing belt needs attention.

Maintenance Tips

To ensure that timing belts function optimally, users should consider the following maintenance tips

- Regular Inspections Periodically check the timing belt for signs of wear, such as fraying or cracks. - Proper Tension Ensure that the belt is appropriately tensioned. Too tight or too loose can lead to issues in performance. - Professional Servicing It’s advisable to have the machine professionally serviced at least once a year, especially for heavy users.

Conclusion

Timing belts are fundamental components that significantly impact the performance and reliability of sewing machines. By understanding their importance and how to maintain them, users can ensure that their sewing machines operate smoothly and produce high-quality results. Whether you are a casual sewer or a seasoned professional, paying attention to the condition of your timing belts will go a long way in maintaining the longevity and efficiency of your sewing machine.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025