- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jun . 12, 2024 11:58 Back to list

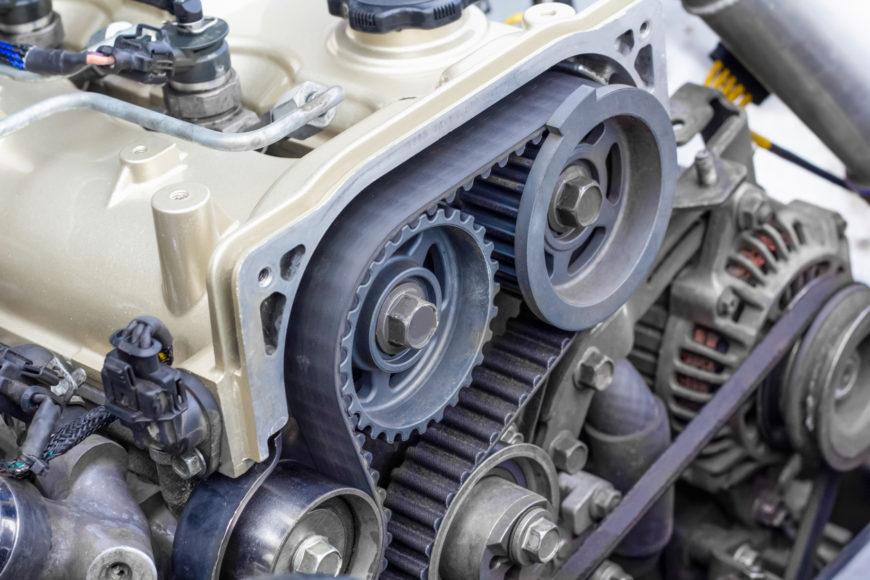

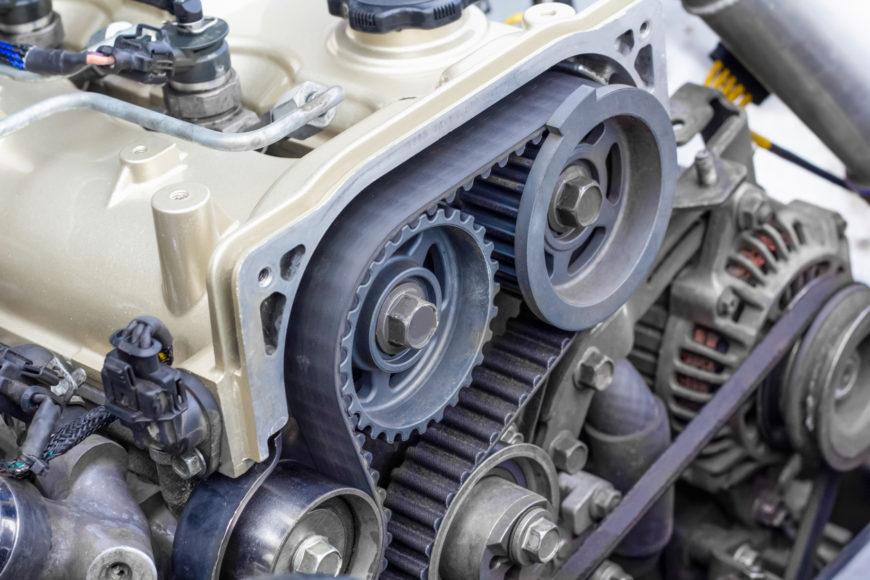

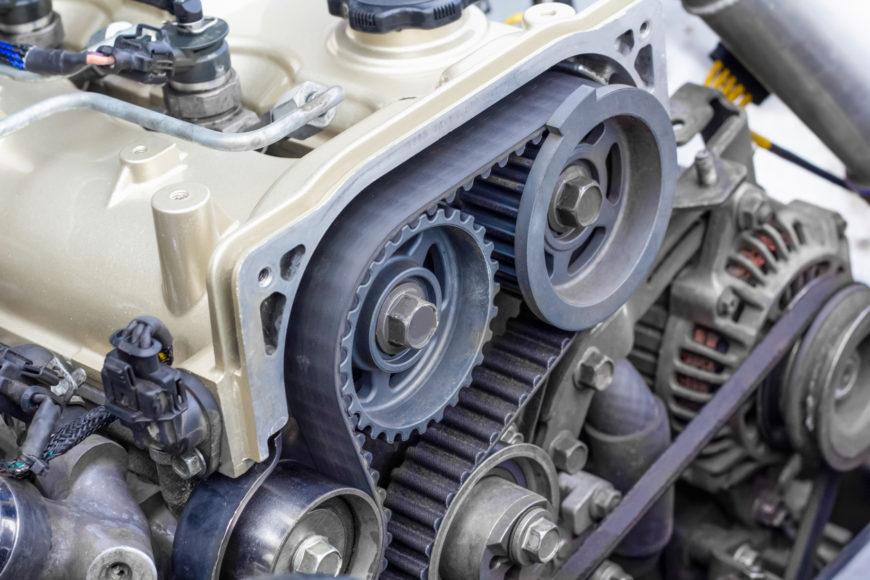

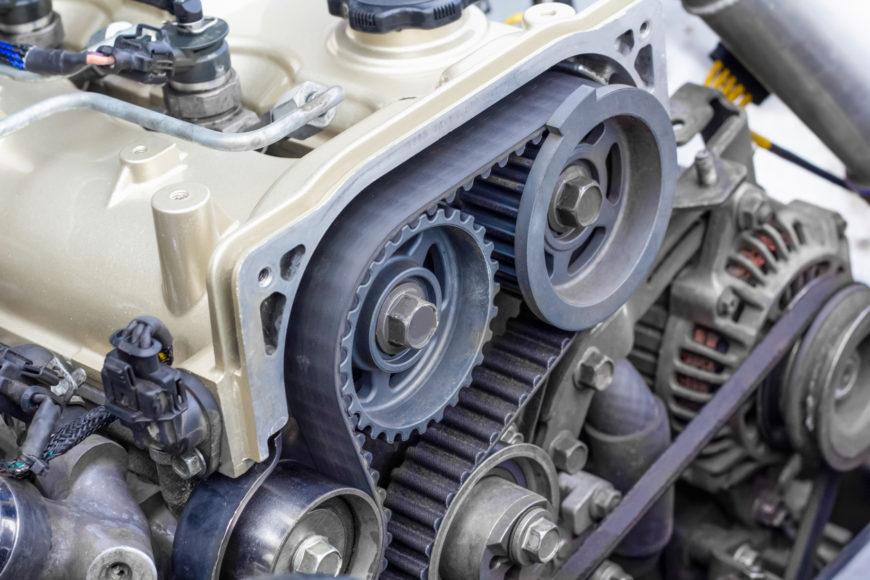

Rubber power transmission belts

The Indispensable Role of Rubber Drive Belts in Modern Industry

Rubber drive belts, a seemingly insignificant component in the vast machinery of modern industry, play an essential role in power transmission and mechanical operations. These versatile and robust belts, composed primarily of rubber, are integral to numerous applications across various sectors, from automotive engines to agricultural equipment, and even in the manufacturing of consumer goods.

Drive belts, often referred to as V-belts, flat belts, or synchronous belts, have a rich history dating back to the Industrial Revolution. The introduction of rubber as the primary material significantly enhanced their efficiency and durability. Rubber, with its inherent elasticity, allows for flexibility while maintaining strength, ensuring a smooth and efficient transfer of power from the driving shaft to the driven components.

One of the key advantages of rubber drive belts is their ability to transmit high torque with minimal slippage. The elastomeric nature of rubber enables it to conform to the pulley's surface, creating a firm grip and enhancing the transmission efficiency. This characteristic is particularly crucial in high-speed and high-power applications where precision and stability are paramount.

Moreover, rubber's inherent shock-absorbing properties help reduce vibration and noise during operation, contributing to a more silent and stable system. Its resistance to wear and tear, combined with its capacity to withstand varying temperatures, makes rubber drive belts highly durable and suitable for harsh operating conditions.

In the automotive industry, rubber drive belts are vital for engine operations

In the automotive industry, rubber drive belts are vital for engine operations In the automotive industry, rubber drive belts are vital for engine operations

In the automotive industry, rubber drive belts are vital for engine operations

In the automotive industry, rubber drive belts are vital for engine operations

In the automotive industry, rubber drive belts are vital for engine operations rubber drive belts. They power essential components such as alternators, water pumps, and power steering systems. In agriculture, they facilitate the smooth running of heavy machinery like harvesters and tractors. In manufacturing plants, they drive conveyor systems, ensuring seamless production processes.

However, it's not just about functionality; the design and engineering of rubber drive belts have evolved over time. Modern versions incorporate advanced materials and technologies, such as high-tensile fabric reinforcements and polyurethane coatings, which further enhance their performance and lifespan.

Despite the advent of alternative technologies like electric motors and direct drives, rubber drive belts remain a staple due to their cost-effectiveness, simplicity, and adaptability. They offer a reliable, low-maintenance solution for power transmission in a wide range of applications.

In conclusion, rubber drive belts, with their unique blend of resilience, adaptability, and efficiency, continue to be an indispensable part of the industrial landscape. As technology advances, these humble belts will likely undergo further innovation, ensuring their continued relevance in driving the world forward.

rubber drive belts. They power essential components such as alternators, water pumps, and power steering systems. In agriculture, they facilitate the smooth running of heavy machinery like harvesters and tractors. In manufacturing plants, they drive conveyor systems, ensuring seamless production processes.

However, it's not just about functionality; the design and engineering of rubber drive belts have evolved over time. Modern versions incorporate advanced materials and technologies, such as high-tensile fabric reinforcements and polyurethane coatings, which further enhance their performance and lifespan.

Despite the advent of alternative technologies like electric motors and direct drives, rubber drive belts remain a staple due to their cost-effectiveness, simplicity, and adaptability. They offer a reliable, low-maintenance solution for power transmission in a wide range of applications.

In conclusion, rubber drive belts, with their unique blend of resilience, adaptability, and efficiency, continue to be an indispensable part of the industrial landscape. As technology advances, these humble belts will likely undergo further innovation, ensuring their continued relevance in driving the world forward.

In the automotive industry, rubber drive belts are vital for engine operations

In the automotive industry, rubber drive belts are vital for engine operations

In the automotive industry, rubber drive belts are vital for engine operations

In the automotive industry, rubber drive belts are vital for engine operations rubber drive belts. They power essential components such as alternators, water pumps, and power steering systems. In agriculture, they facilitate the smooth running of heavy machinery like harvesters and tractors. In manufacturing plants, they drive conveyor systems, ensuring seamless production processes.

However, it's not just about functionality; the design and engineering of rubber drive belts have evolved over time. Modern versions incorporate advanced materials and technologies, such as high-tensile fabric reinforcements and polyurethane coatings, which further enhance their performance and lifespan.

Despite the advent of alternative technologies like electric motors and direct drives, rubber drive belts remain a staple due to their cost-effectiveness, simplicity, and adaptability. They offer a reliable, low-maintenance solution for power transmission in a wide range of applications.

In conclusion, rubber drive belts, with their unique blend of resilience, adaptability, and efficiency, continue to be an indispensable part of the industrial landscape. As technology advances, these humble belts will likely undergo further innovation, ensuring their continued relevance in driving the world forward.

rubber drive belts. They power essential components such as alternators, water pumps, and power steering systems. In agriculture, they facilitate the smooth running of heavy machinery like harvesters and tractors. In manufacturing plants, they drive conveyor systems, ensuring seamless production processes.

However, it's not just about functionality; the design and engineering of rubber drive belts have evolved over time. Modern versions incorporate advanced materials and technologies, such as high-tensile fabric reinforcements and polyurethane coatings, which further enhance their performance and lifespan.

Despite the advent of alternative technologies like electric motors and direct drives, rubber drive belts remain a staple due to their cost-effectiveness, simplicity, and adaptability. They offer a reliable, low-maintenance solution for power transmission in a wide range of applications.

In conclusion, rubber drive belts, with their unique blend of resilience, adaptability, and efficiency, continue to be an indispensable part of the industrial landscape. As technology advances, these humble belts will likely undergo further innovation, ensuring their continued relevance in driving the world forward. Share:

Latest news

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025