- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 27, 2024 01:48 Back to list

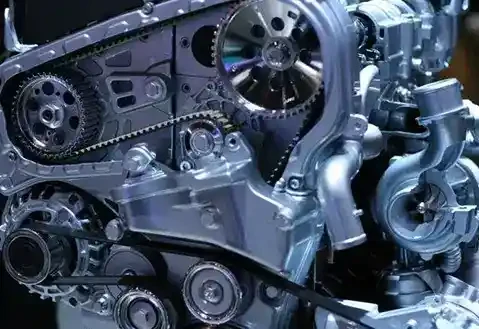

Understanding Truck Engine Belts and Their Importance in Vehicle Performance

Understanding the Importance of Truck Engine Belts

Truck engines are complex systems that play a crucial role in ensuring the efficient performance and reliability of heavy vehicles. Among the various components that contribute to the proper functioning of truck engines, belts are indispensable. These rubber components, often overlooked, are vital for the operation of numerous engine systems. Understanding the significance of truck engine belts, their types, maintenance, and common issues is essential for truck owners and operators who wish to maintain peak performance and prolong their vehicle's lifespan.

The Role of Engine Belts

Truck engine belts serve multiple functions in the overall mechanics of a vehicle

. The two primary types of belts found in truck engines are the serpentine belt and the timing belt.- Serpentine Belts These long, continuous belts are designed to drive multiple peripheral devices such as the alternator, power steering pump, air conditioning compressor, and water pump. They are crucial for the efficient operation of these systems, ensuring that the engine runs smoothly and that ancillary components receive the power they need to function effectively.

- Timing Belts Unlike serpentine belts, timing belts are responsible for synchronizing the rotation of the crankshaft and camshaft. This synchronization is essential for maintaining the engine's timing, ensuring that the engine's valves open and close at the correct intervals. A malfunctioning timing belt can lead to severe engine damage, making it one of the most critical components of a truck engine.

Maintenance of Truck Engine Belts

Proper maintenance of truck engine belts is key to avoiding breakdowns and costly repairs. Regular inspections are essential to identify wear and tear, such as cracks, fraying, or stretching. Drivers and technicians should keep an eye on the following signs that indicate a belt replacement may be necessary

1. Cracks and Fraying Look for visible signs of wear on the belt surface. Cracks can compromise the belt's strength, leading to sudden failure.

2. Squeaking or Squealing Noises Unusual sounds can indicate slippage or improper tension in the belt. Addressing these noises promptly can prevent more significant issues.

truck engine belt

3. Engine Warning Lights Modern trucks are equipped with diagnostic systems that may indicate a problem with the belts. Ignoring these warnings can lead to more significant engine issues.

4. Regular Replacement It's advisable to follow the manufacturer's recommendations for belt replacement intervals. Over time, belts degrade due to heat, tension, and environmental factors, making routine replacements essential for longevity.

Common Issues and Solutions

Several common issues can arise with truck engine belts, all of which require prompt attention to avoid serious mechanical problems.

- Belt Slippage This can occur if the belt is worn out or if the tensioning mechanism fails. Regular tension checks and replacements can mitigate this issue.

- Fractures and Breakage Although modern materials are designed for durability, factors like age, heat exposure, and environmental conditions can lead to breakage. When a belt breaks, it can cause complete engine failure or damage to other components.

- Misalignment Misaligned belts can lead to uneven wear and reduced efficiency. Technicians should ensure that pulleys and components are correctly aligned during maintenance checks.

Conclusion

Truck engine belts may seem like minor components in the grand scheme of engine mechanics, but their importance cannot be overstated. By understanding their roles, maintaining them routinely, and addressing common issues promptly, truck owners and operators can ensure reliable vehicle performance and extend the life of their engines. Regular maintenance of engine belts is not just a recommendation; it is a necessity for the longevity and efficiency of every truck on the road. Emphasizing the care of these components is key to achieving optimal performance and minimizing the risk of breakdowns, ultimately leading to safer and more economical transport solutions.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025