- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Oct . 21, 2024 23:13 Back to list

Understanding the Benefits of a 5.3% Serpentine Belt for Your Vehicle

Understanding the 5.3% Serpentine Belt Importance, Function, and Maintenance

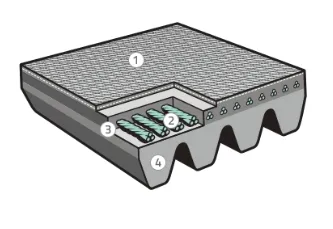

The serpentine belt is a crucial component in modern automotive engines, connecting multiple engine accessories to the crankshaft. It plays a significant role in the overall functionality and efficiency of a vehicle. Among the various specifications and types of serpentine belts available, the 5.3% serpentine belt stands out due to its unique design and performance characteristics. In this article, we will explore the significance, operation, and maintenance of the 5.3% serpentine belt.

Importance of the Serpentine Belt

The serpentine belt, often referred to as a multi-rib or drive belt, is responsible for driving several components with a single belt. These components typically include the alternator, power steering pump, water pump, air conditioning compressor, and sometimes, the coolant pump. The design of the serpentine belt allows it to be more efficient compared to older V-belts, which required multiple belts to perform the same function.

The 5.3% designation refers to the specific construction and performance parameters of this belt, indicating its percentage of elasticity or maybe its width in a technical capacity. This specification plays a crucial role in how effectively the belt operates under various load conditions. A serpentine belt with a 5.3% design is engineered to provide optimum flexibility and grip, ensuring that all connected accessories receive adequate power without slippage, thus enhancing the overall performance of the engine.

Functionality of the Serpentine Belt

The operation of a serpentine belt is relatively straightforward. As the engine runs, the crankshaft turns, which in turn rotates the serpentine belt. This rotation transfers power to all the connected accessories through a series of grooves that ensure a tight and secure fit. The 5.3% design helps maintain the necessary tension and flexibility for smooth operation.

5.3 serpentine belt

One of the advantages of the serpentine belt system is that it generally incorporates a tensioner—an adjustable mechanism that maintains the belt’s tension over time. This is important because belts stretch as they age, and maintaining proper tension prevents slipping and potential engine damage. Regular use of a 5.3% serpentine belt ensures that all engine systems work in harmony, contributing not only to engine efficiency but also to the longevity of the vehicle’s components.

Maintenance of the Serpentine Belt

Maintaining the serpentine belt does not have to be a complicated process. However, it is crucial to monitor its condition regularly. Signs of wear include fraying, cracking, or shiny surfaces, all indicating that it may be time for a replacement. A typical serpentine belt has a lifespan of 60,000 to 100,000 miles, but this can vary based on driving conditions and behaviors.

To ensure the longevity of a 5.3% serpentine belt, drivers should adhere to the manufacturer's maintenance schedules and recommendations. During routine maintenance checks, mechanics will often inspect the tensioner and pulleys for wear, ensuring the entire system operates smoothly. Furthermore, if any accessory driven by the serpentine belt begins to malfunction, it could place additional strain on the belt, prompting immediate inspection or replacement.

Conclusion

The 5.3% serpentine belt is an integral part of modern automotive engineering, providing essential services that support the necessary functions of a vehicle. Understanding its importance, functionality, and maintenance needs allows drivers to ensure the longevity and efficiency of their vehicles. By staying proactive with inspections and staying informed about the condition of the serpentine belt, vehicle owners can enhance their car’s performance and avoid unnecessary breakdowns.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025