- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

сеп . 29, 2024 09:15 Back to list

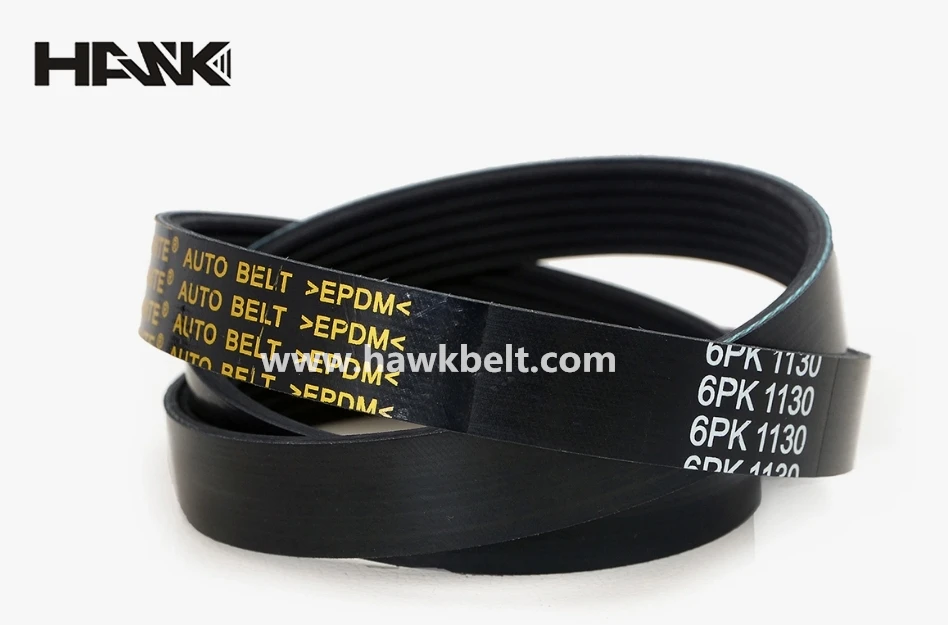

Choosing the Right Poly V-Belt for Optimal Performance and Durability in Your Machinery

Understanding Poly V-Belt PK A Comprehensive Guide

In the world of mechanical engineering and automotive design, the choice of drive belts is crucial for efficient power transmission. One significant type of belt that has garnered attention in recent years is the Poly V-belt, specifically the PK series. This article aims to provide a comprehensive overview of Poly V-belts, their advantages, applications, and why the PK series stands out in this competitive field.

What is a Poly V-Belt?

A Poly V-belt is a type of V-belt characterized by multiple grooves or ribs running parallel to its length. This design allows for greater contact with the pulleys, enhancing grip and enabling higher power transmission efficiency. The Poly designation reflects its multi-ribbed nature, while the V indicates its wedge-shaped profile. The smooth back side of a Poly V-belt also allows for a reduction in friction, leading to lower energy losses compared to traditional V-belts.

Features and Advantages of PK Series Poly V-Belts

The PK series of Poly V-belts is particularly noted for its durability and versatility

. Here are some key features and advantages1. Compact Design The PK series is designed for applications where space is a premium. The narrow profile allows it to fit into compact machinery and drive systems without sacrificing power delivery.

2. High Torque Transmission Poly V-belts excel in transmitting high torque, making them suitable for demanding applications such as automotive engines and industrial machinery.

3. Reduced Slip and Noise The intricate ribbed design minimizes slippage between the belt and the pulleys, ensuring that the power transfer remains efficient. Additionally, the smooth operation results in reduced noise during operation, an essential aspect in environments where sound levels need to be minimized.

4. Heat Resistance Many PK series Poly V-belts are manufactured with materials that withstand elevated temperatures, making them ideal for applications exposed to heat, such as engines and generators.

5. Longevity The robust construction of PK belts typically leads to a longer service life compared to standard belts, reducing maintenance and replacement costs over time.

poly v-belt pk

Applications of Poly V-Belt PK

The versatility of Poly V-belt PK makes it suitable for various applications across multiple industries. Some common uses include

- Automotive Industry Poly V-belts are often employed in automotive accessory drives where space and power efficiency are critical, such as in alternators, power steering pumps, and air conditioning compressors.

- Industrial Machinery In manufacturing and production facilities, Poly V-belts are used to drive conveyors, fans, and other machinery where high torque and compact design are required.

- Consumer Appliances Equipment like washing machines and dryers often utilize Poly V-belts due to their reliability and compact design, contributing to the overall efficiency of these appliances.

- Agricultural Machinery In farming equipment, Poly V-belts can handle the rigorous demands of driving various components, ensuring that machines operate smoothly and reliably.

Conclusion

The PK series of Poly V-belts represents a significant advancement in drive technology, combining compact design with high torque capabilities and durability. As industries continue to evolve towards more efficient and space-saving solutions, the demand for Poly V-belts, particularly the PK series, will likely grow.

Whether in automotive applications, industrial settings, or consumer appliances, the enhanced performance, longevity, and efficiency of PK Poly V-belts make them a preferred choice for engineers and manufacturers alike. Understanding the properties of these belts allows engineers to optimize designs and improve machinery performance, ultimately leading to greater operational efficiency and reduced costs.

In summary, Poly V-belt PK is a sophisticated solution to modern engineering challenges, embodying a perfect balance of power, efficiency, and practicality. As the industry moves forward, adopting such technologies will be crucial for achieving excellence in performance and sustainability.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025