- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

дец . 09, 2024 15:30 Back to list

flat rubber belt material

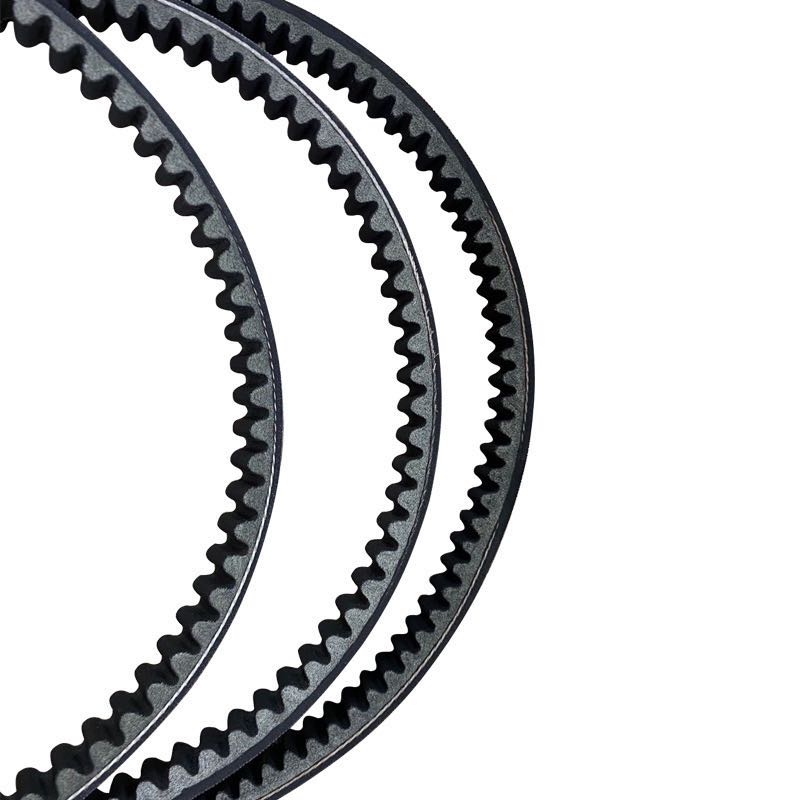

Understanding Flat Rubber Belt Materials A Comprehensive Overview

Flat rubber belts are essential components in various industrial applications, serving as crucial links in the transfer of power and motion between machinery. These belts are designed to withstand various stresses and strains while maintaining flexibility and durability. This article explores the different types of flat rubber belt materials, their properties, and their applications in various industries.

Types of Flat Rubber Belt Materials

Flat rubber belts are typically made from a mixture of rubber and other materials to enhance their performance and longevity. The most common types of rubber used include natural rubber, neoprene, and polyurethane.

1. Natural Rubber Known for its excellent elasticity and tensile strength, natural rubber is derived from latex obtained from rubber trees. While it offers superior performance in terms of flexibility, it can be susceptible to abrasive wear and degradation from exposure to ozone and UV light. Therefore, natural rubber belts are best suited for indoor applications or in environments where they are not exposed to harsh conditions.

2. Neoprene A synthetic rubber, neoprene offers enhanced resistance to oil, chemicals, and weathering, making it an ideal choice for applications in petrochemical and food processing industries. Neoprene belts can also withstand temperature fluctuations, making them suitable for both cold and hot environments. This versatility has led to the widespread adoption of neoprene in various mechanical systems.

3. Polyurethane Known for its exceptional abrasion resistance, polyurethane belts are often used in high-load applications where durability is crucial. Polyurethane exhibits a high level of tensile strength and tear resistance, making it suitable for environments where belts are subjected to significant wear and tear. Its lightweight nature and flexibility also allow for easier handling and installation.

Properties of Flat Rubber Belts

When selecting flat rubber belts, various properties must be taken into account to ensure optimal performance in specific applications. These properties include

- Tensile Strength The ability of a belt to withstand pulling forces without breaking. Higher tensile strength typically indicates a more robust belt.

- Elongation The measure of how much the belt can stretch before it breaks

. A higher elongation percentage indicates greater flexibility, which may be necessary for certain applications.flat rubber belt material

- Temperature Resistance Different materials resist heat to varying degrees. Understanding the thermal limits of the belt material is essential to avoid premature failure in high-temperature environments.

- Abrasion Resistance The ability of the belt to withstand surface wear caused by friction. Adequate abrasion resistance is vital for prolonging the belt's lifespan in tough operating conditions.

Applications of Flat Rubber Belts

Flat rubber belts are used in a multitude of applications across various sectors

- Manufacturing In manufacturing settings, flat rubber belts are often utilized in conveyor systems, transporting materials and products throughout the production line.

- Automotive In the automotive industry, these belts are integral to the power transmission systems, connecting various engine components and ensuring smooth operation.

- Food Processing Given their resistance to chemicals and easy cleaning capabilities, flat rubber belts are widely used in the food processing industry for transporting food products while meeting health and safety standards.

- Agriculture In agriculture, flat rubber belts are employed in various machinery, from harvesting equipment to irrigation systems, helping to optimize productivity and efficiency.

Conclusion

Flat rubber belt materials are a pivotal component in countless applications across diverse industries. By understanding the different types of materials and their respective properties, businesses can make informed decisions to choose the right belt for their specific needs. As technology advances, the development of new materials and manufacturing processes will likely continue to enhance the performance and efficiency of flat rubber belts, driving innovation across various sectors.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025