- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

окт . 11, 2024 07:03 Back to list

drive belts

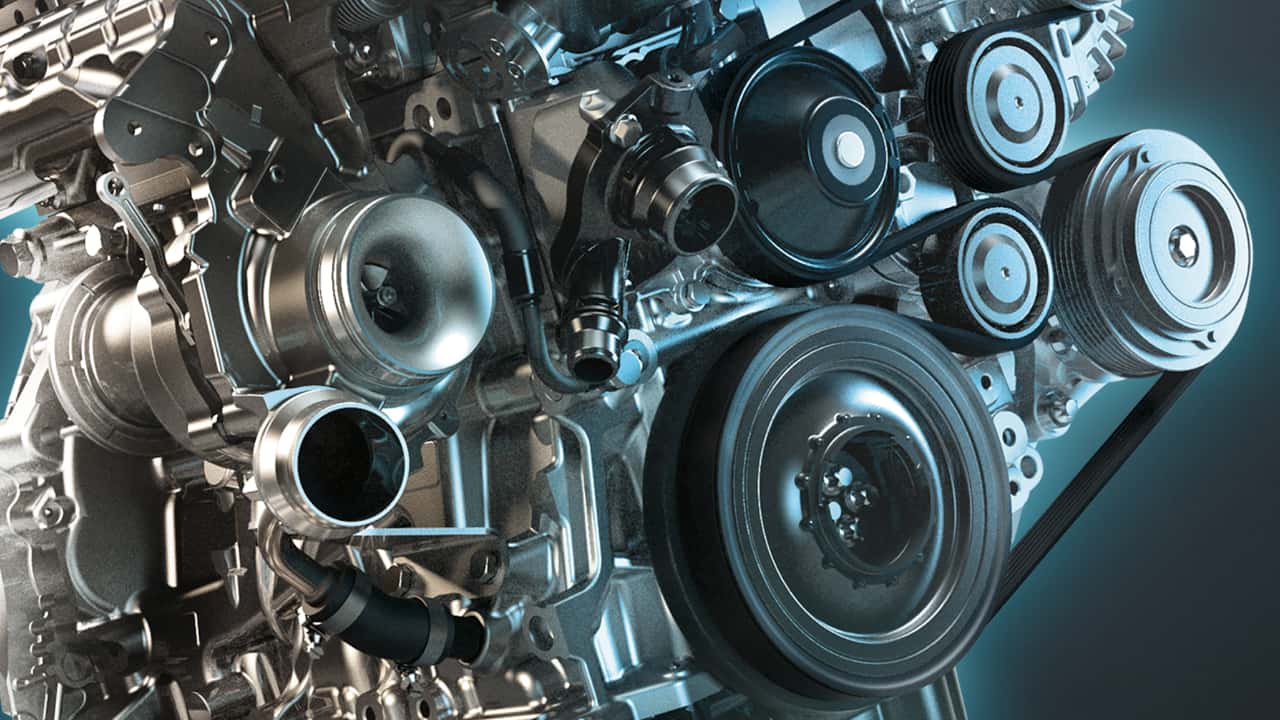

Understanding Drive Belts A Key Component in Mechanical Systems

Drive belts are essential components in many mechanical systems, serving as the link between different parts of a machine to transmit power and motion. These flexible loops of material are vital in various applications, from automotive engines to industrial machinery. In this article, we will explore the importance, types, and applications of drive belts.

Types of Drive Belts

There are several types of drive belts, each designed for specific applications and operating conditions

. The most common types include1. V-Belts Characterized by their trapezoidal cross-section, V-belts are designed to fit snugly into matching grooves on pulleys. They provide excellent grip and can handle high loads and speeds. V-belts are widely used in automotive engines and industrial machines.

2. Flat Belts These belts have a flat cross-section and are primarily used in applications where high-speed and long-distance power transmission are required. Flat belts are commonly found in conveyor systems and machinery where a large surface area contact is beneficial.

3. Timing Belts Timing belts are designed with teeth that mesh with corresponding grooves on pulleys, ensuring precise synchronization of moving parts. They are often used in applications where timing is critical, such as in camshaft drives in automotive engines.

4. Toothed Belts Similar to timing belts, toothed belts provide positive engagement with pulleys. They are typically employed in applications requiring high power transmission and minimal slippage, such as in some manufacturing equipment.

drive belts

Applications

Drive belts are ubiquitous in both consumer and industrial applications. In the automotive industry, they play a pivotal role in driving components like the alternator, water pump, and air conditioning compressor. The reliability and performance of the vehicle can significantly depend on the condition of these belts.

In industrial settings, drive belts facilitate the operation of various machinery, from conveyor systems to textile manufacturing equipment. Their ability to transmit power efficiently makes them integral to the smooth operation of production lines.

Maintenance and Replacement

Like any mechanical component, drive belts require regular inspection and maintenance. Over time, they can wear out due to factors such as heat, friction, and environmental conditions. Signs of a worn belt include cracks, fraying, or unusual noises during operation. Regular checking and timely replacement of drive belts are essential to prevent mechanical failures and ensure the longevity of the equipment.

Conclusion

Drive belts are crucial for efficient power transmission in various mechanical systems. Understanding the different types and their specific applications can help in choosing the right belt for your needs. With proper maintenance and timely replacements, drive belts can contribute significantly to the overall performance and reliability of machinery across multiple industries.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025