- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 09, 2024 17:07 Back to list

Compatible V Ribbed Belts for Enhanced Performance and Reliability in Various Applications

Understanding V Ribbed Belts and Their Advantages

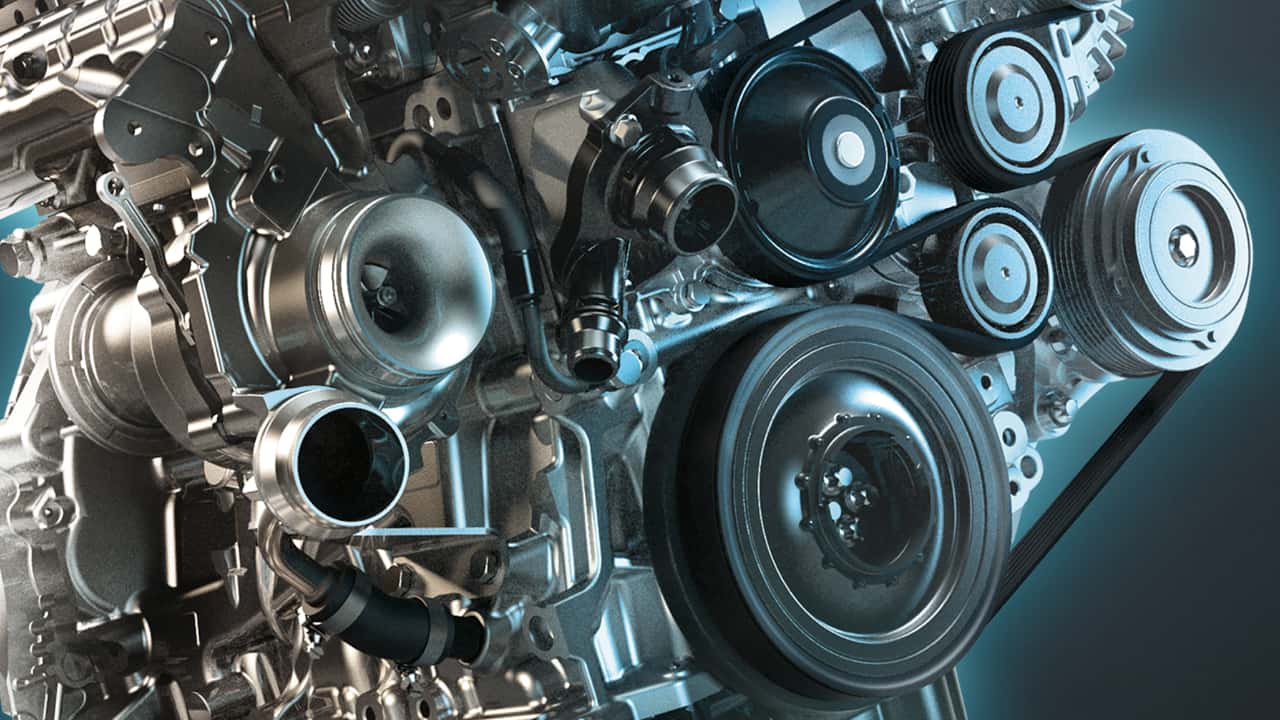

V ribbed belts, also known as serpentine belts or multi-ribbed belts, play a crucial role in the functionality of modern automotive and industrial systems. These belts are designed to transmit power from the engine to various components such as the alternator, air conditioning compressor, power steering pump, and water pump. Characterized by their unique ribbed design, v ribbed belts offer several advantages that enhance performance and efficiency.

Structure and Design

The design of v ribbed belts is one of their most significant features. Unlike traditional flat belts, v ribbed belts have multiple ribs that run parallel to each other along the length of the belt. This ribbed configuration allows for a larger contact area with the pulleys, resulting in improved grip and minimal slippage. Typically made from high-quality rubber compounds, these belts are engineered to withstand harsh conditions, resist wear and tear, and operate efficiently over extended periods.

Enhanced Power Transmission

One of the primary benefits of using v ribbed belts is their enhanced power transmission capabilities. The design allows for the distribution of power to multiple accessories at once, eliminating the need for several individual belts. This efficiency not only simplifies the engine compartment but also reduces the overall weight of the vehicle, leading to better fuel efficiency. For industrial applications, the same principles apply, as v ribbed belts can effectively drive multiple machinery elements simultaneously.

Improved Durability and Longevity

v ribbed belts 3288724

Durability is another crucial attribute of v ribbed belts. They are engineered to resist stretching, cracking, and abrasion, making them a reliable choice for both automotive and industrial applications. The advanced materials used in their construction provide resistance to extreme temperatures and harsh environmental conditions, ensuring longevity. Routine inspections and timely replacements can further enhance the lifespan of these belts, ensuring that they continue to perform optimally.

Noise Reduction

V ribbed belts also contribute to reduced operational noise. The ribbed design minimizes vibrations, leading to a smoother operation of the connected components. This is particularly important in automotive applications, where noise reduction can significantly enhance the overall driving experience. Consumers increasingly demand quieter engines and smoother rides, and v ribbed belts help manufacturers meet these expectations.

Maintenance and Replacement

Despite their durability, v ribbed belts do require regular maintenance checks. It is essential to inspect for signs of wear, such as cracks, fraying, or glazing on the belt surface. Replacing a worn-out v ribbed belt is a relatively straightforward process but is critical for maintaining the performance of the engine and its components. Neglecting to replace a failing belt can lead to cascading failures of engine accessories, potentially resulting in costly repairs.

Conclusion

In summary, v ribbed belts, such as the 3288724 model, are essential components in modern automotive and industrial systems. Their unique ribbed design enhances power transmission, improves durability, reduces noise, and simplifies maintenance. As technology continues to advance, the materials and manufacturing processes used in producing these belts will only improve, leading to more efficient and reliable engine performance. As such, understanding their benefits and ensuring proper maintenance can lead to better operational efficiency and extended longevity in both vehicles and machinery.

-

Upgrade Power Steering Pump Belt for Smooth, Quiet Operation

NewsAug.27,2025

-

Precision Timing Belt & Chain: Engine Performance & Durability

NewsAug.26,2025

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025