- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Dec . 09, 2024 15:40 Back to list

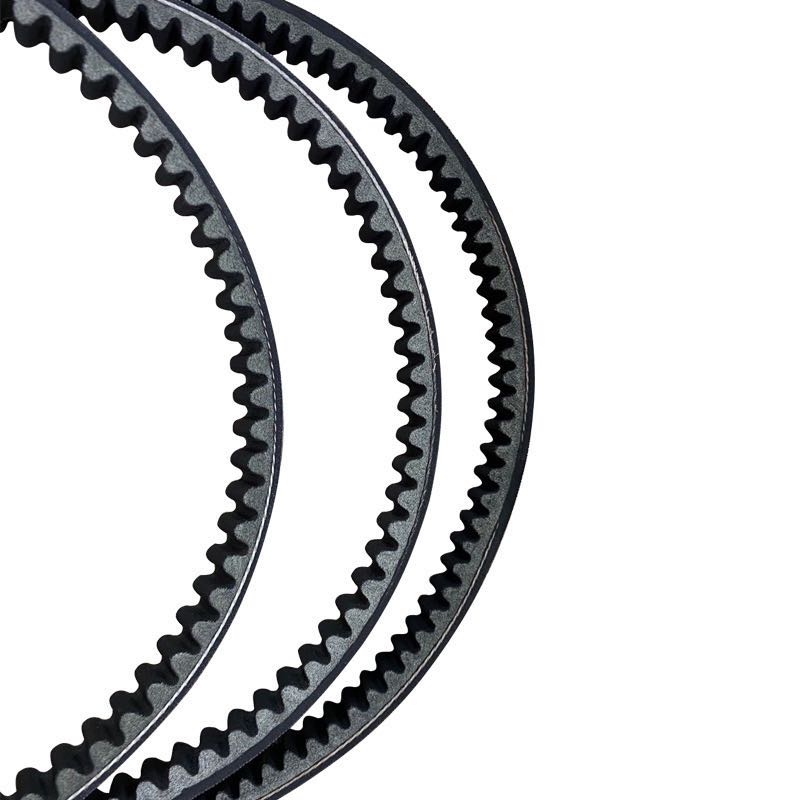

drive belt slipping

Understanding Drive Belt Slipping Causes, Effects, and Solutions

Drive belts play a crucial role in the functioning of various machinery and automotive systems. Whether it's in cars, motorcycles, or industrial equipment, these belts transfer power from one component to another, maintaining the efficient operation of the system. However, one common issue that can arise with drive belts is slipping. This article will explore what drive belt slipping is, its causes, effects, and potential solutions.

What is Drive Belt Slipping?

Drive belt slipping occurs when the belt does not maintain proper tension or grip on the pulleys it is meant to drive. This can lead to a loss of power transmission, resulting in degraded performance. For vehicles, this might manifest as a reduction in engine power, compromised accessory function, or unusual noises emanating from the engine compartment. In industrial machinery, slipping belts can lead to equipment downtime and decreased productivity.

Causes of Drive Belt Slipping

Several factors can contribute to drive belt slipping, including

1. Wear and Tear Over time, belts experience wear and tear, which can lead to a loss of grip. Factors such as extreme temperatures, oil exposure, and contaminants can accelerate this degradation.

2. Improper Tension If the belt is either too loose or too tight, it may slip. New belts require a break-in period, and regular adjustments may be needed to maintain optimal tension.

3. Misalignment Pulleys that are misaligned can affect the belt’s path, causing uneven tension and increasing the likelihood of slipping.

4. Contamination Oils, grease, and other substances can decrease the friction between the belt and the pulleys, leading to slipping. This is particularly problematic in automotive applications where leaks can occur.

5. Cold Weather In colder temperatures, materials contract, making the belt stiff and less flexible. This can increase the chances of slipping, especially when the engine is first started.

Effects of Drive Belt Slipping

drive belt slipping

The consequences of drive belt slipping can vary depending on the application. In vehicles, slipping can lead to

- Decreased engine performance. - Diminished power steering assistance. - Issues with air conditioning operation.

In industrial settings, slipping belts may result in

- Inefficient machinery operation. - Increased wear on components. - Production delays and potential financial losses.

Solutions and Preventive Measures

To mitigate drive belt slipping, several solutions can be implemented

1. Regular Inspection Routine inspections can help identify wear and other issues early. Check for cracks, fraying, and other signs of damage.

2. Optimal Tension Ensure that belts are installed with the correct tension, referred to as the manufacturer's specifications. Tools like a tension gauge can assist in achieving the ideal tension.

3. Alignment Checks Regularly check the alignment of pulleys to ensure that they are properly positioned. Misalignment can often be corrected by adjusting mounting brackets or replacing faulty components.

4. Cleaning Keeping the belt and pulleys clean from oils and contaminants is essential. Using appropriate cleaners designed for this task can help maintain the grip needed for optimal performance.

5. Replacement If a belt shows significant signs of wear or damage, replace it immediately to prevent further issues.

In conclusion, drive belt slipping is a common issue that can lead to significant performance problems in various systems. By understanding its causes, effects, and preventive measures, users can ensure the longevity and efficiency of their machinery and vehicles. Regular maintenance and timely interventions can go a long way in preventing the frustration and costs associated with slipping belts.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025