- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Nov . 14, 2024 14:37 Back to list

timing belt factory

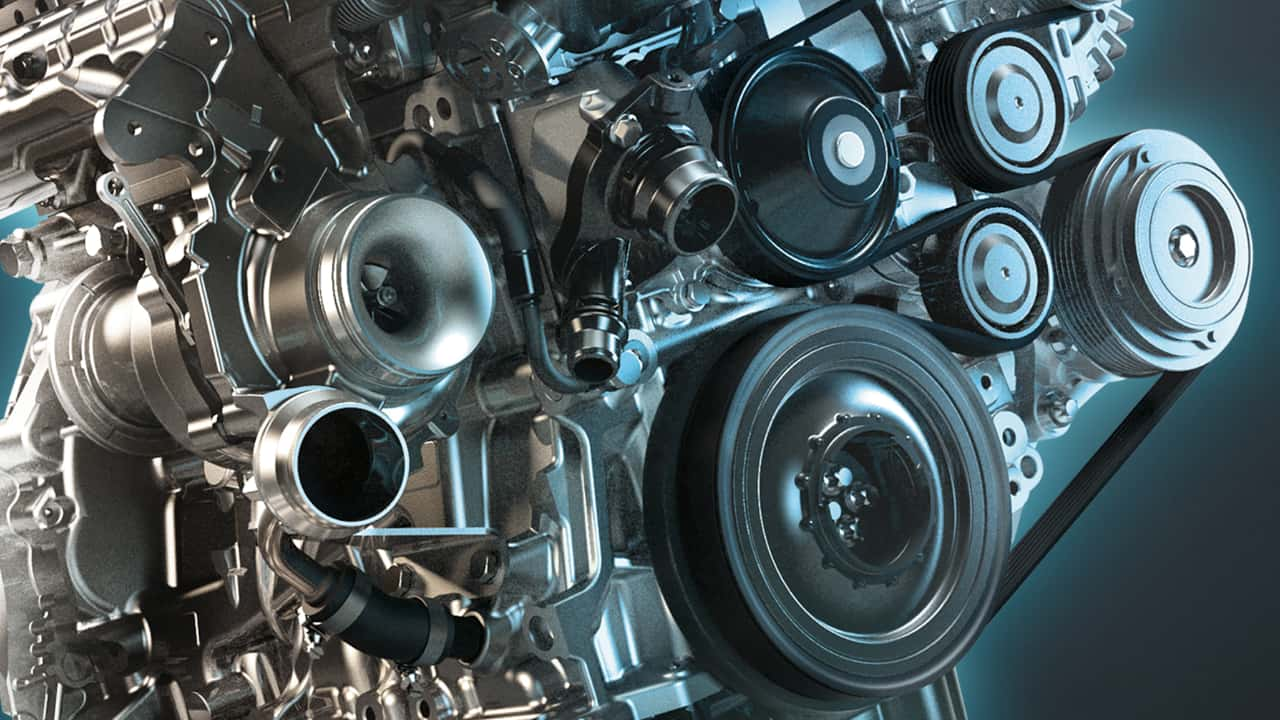

The Importance of Timing Belt Factories in Modern Engineering

In the realm of modern engineering and automotive manufacturing, timing belts play a crucial role in ensuring the efficient functioning of internal combustion engines. A timing belt factory specializes in producing these vital components that synchronize the rotation of the crankshaft and camshaft, allowing for the proper timing of valve openings and closings. Without high-quality timing belts, engines would falter, leading to reduced performance and potential mechanical failures.

Timing belts are typically made from reinforced rubber, featuring teeth that grip the gears of the engine’s components. The design of these belts must withstand intense heat and friction, making the manufacturing process both intricate and highly technical. Timing belt factories invest heavily in research and development to create materials that offer durability and resistance to wear and tear. This not only enhances the longevity of the belts but also ensures safety in automotive operations.

The production process in a timing belt factory involves several meticulous steps. First, raw materials are carefully selected and treated to enhance their properties. The manufacturing process then proceeds to the molding phase, where the rubber is shaped into belts with specific dimensions and tooth configurations. Quality control is critical at every stage; engineers conduct rigorous testing to ensure that each belt meets the industry standards before it is rolled out for use.

timing belt factory

In recent years, advancements in technology have revolutionized the timing belt manufacturing process. Automation has significantly increased production efficiency, enabling factories to produce large quantities of belts with precision. Computer-aided design (CAD) tools allow engineers to create optimal belt designs tailored to diverse engine types. Moreover, the introduction of smart manufacturing technologies has facilitated real-time monitoring of production processes, leading to increased quality assurance and reduced waste.

Timing belt factories also play a vital role in the aftermarket car parts industry. As vehicles age, the need for replacement parts becomes inevitable. High-quality timing belts manufactured in specialized factories are essential for maintaining vehicle performance and reliability. With the rising trend of vehicle customization, aftermarket timing belts are available in various designs and specifications to meet the needs of different automotive enthusiasts.

Furthermore, as the automotive industry shifts towards electric vehicles (EVs), timing belt factories are adapting to new technologies. While electric engines do not require traditional timing belts, the expertise gained from manufacturing these components is being applied to new areas, such as producing belts and accessories for hybrid vehicles and other non-automotive applications. The versatility of timing belt factories underscores their importance in the broader manufacturing landscape.

In conclusion, timing belt factories are indispensable to the automotive industry and beyond. They combine advanced materials science and engineering to produce components that are essential for the proper functioning of engines. As technology continues to evolve, these factories will remain at the forefront of innovation, ensuring that vehicles operate safely and efficiently while adapting to the changing demands of the transportation sector. The role of timing belt factories will only grow in importance, influencing automotive performance and engineering practices for years to come.

-

Durable Diesel Engine Belt with GPT-4-Turbo AI Tech | Precision Fit

NewsAug.04,2025

-

High-Quality Tensioner Belt Pulley - Durable & Efficient

NewsAug.03,2025

-

Premium Timing Belt Factory | AI-Optimized Solutions

NewsAug.02,2025

-

Premium Custom V Belts Enhanced with GPT-4 Turbo AI

NewsAug.01,2025

-

Car Serpentine Belt: AI-Optimized Performance with GPT-4-Turbo

NewsJul.31,2025

-

Heat Joining Drive Belt | High-Durability Fusion Solution

NewsJul.31,2025