- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Sep . 06, 2024 21:38 Back to list

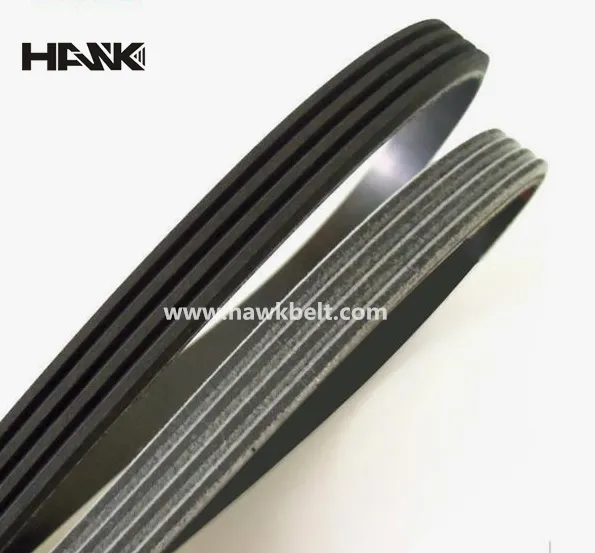

High-Quality Motor Belts for Optimal Performance

Understanding Motor Belts Essential Components of Mechanical Systems

Motor belts are crucial components in various mechanical systems, playing a vital role in the transfer of power and motion between different parts. Found in machinery ranging from automobiles to industrial equipment, these belts enable the efficient operation of motors by connecting pulleys or gears, ensuring smooth and reliable performance.

Motor belts function on a simple principle they transmit rotational force from one component to another through friction. This process occurs when a belt wraps around a pulley, allowing it to transfer energy from the motor to the driven equipment. The effectiveness of a motor belt relies significantly on its material, design, and tension, all of which influence its efficiency and longevity.

There are several types of motor belts, each designed for specific applications

. The most common types include V-belts, flat belts, synchronous belts, and timing belts. V-belts are characterized by their trapezoidal cross-section, offering superior grip and the ability to handle heavy loads, making them ideal for automotive engines and industrial machines. Flat belts, on the other hand, are utilized in applications requiring high-speed operation and low-tension drive, such as conveyor systems.motor belts

Synchronous belts, also known as timing belts, are designed with teeth that mesh with corresponding grooves on pulleys. This design allows for precise motion control and synchronization, making them suitable for applications requiring accurate timing, such as in robotics and precision machining. Timing belts are often used in conjunction with pulleys to ensure the synchronization of various components in an engine, contributing to optimal performance.

The maintenance of motor belts is essential for ensuring their longevity and the efficiency of the machines they serve. Regular inspection for signs of wear, such as cracking, glazing, or fraying, is vital. Proper tensioning is also crucial, as belts that are too loose may slip, while those that are too tight can lead to premature wear and tear on both the belt and the pulleys.

In summary, motor belts are indispensable components that facilitate the smooth operation of various mechanical systems. Understanding their types, functions, and maintenance is essential for engineers, designers, and anyone involved in the management of mechanical systems. By ensuring proper selection and maintenance of motor belts, we can enhance the performance and reliability of machinery across multiple industries, driving efficiency and innovation in mechanical design.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025