- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ඔක්. . 14, 2024 04:44 Back to list

Understanding XL Timing Belts for Optimal Performance and Durability in Mechanical Systems

Understanding XL Timing Belts A Comprehensive Guide

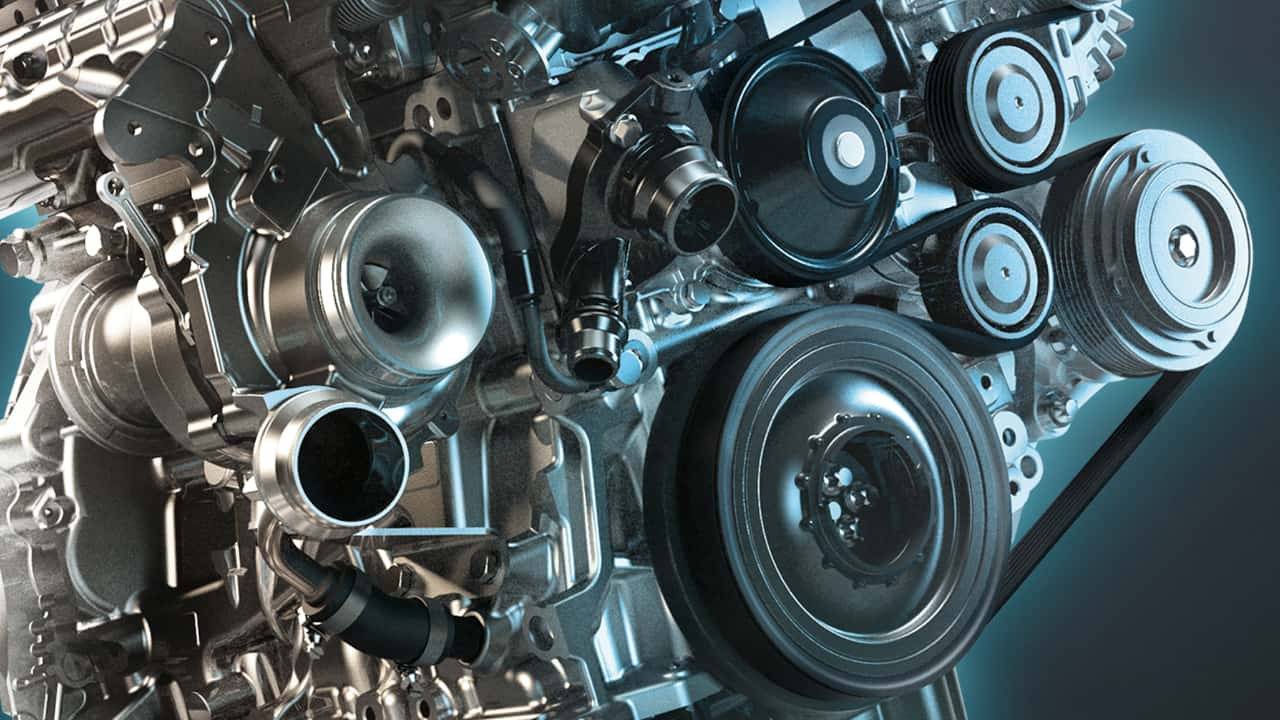

Timing belts play a critical role in the functioning of various machines, particularly in engines and other mechanical systems. Among the varieties of timing belts available in the market, XL timing belts are prominent due to their unique features and applications. This article aims to provide an in-depth overview of XL timing belts, their specifications, applications, and maintenance tips to ensure optimal performance.

What is an XL Timing Belt?

The XL timing belt is a type of synchronous belt designed with specific characteristics that make it suitable for various applications. The XL designation refers to the tooth profile and pitch of the belt. Typically, XL timing belts have a tooth pitch of 5.08 mm (0.200 inches) and are usually made of durable materials like neoprene, reinforced with polyester or fiberglass to enhance strength and flexibility.

Specifications

The specifications of XL timing belts include

- Tooth Pitch 5.08 mm (0.200 inches) - Width XL belts come in various widths, typically ranging from 6 mm to 50 mm, to accommodate different power transmission needs. - Material Common materials include neoprene and urethane, providing longevity and resistance to wear. - Temperature Resistance XL belts can operate effectively in various temperature ranges, making them suitable for diverse environments. - Load Capacity XL timing belts are capable of transmitting power efficiently, making them ideal for both low and high load applications.

Applications

XL timing belts find applications in numerous industries and fields. Some of the most common applications include

1. Robotics In robotics, XL timing belts are often used in positioning systems and drives where synchronized movement is essential.

2. 3D Printers Many 3D printers utilize XL timing belts for precise control of the print head and bed, ensuring accuracy during the printing process.

3. Automotive Within automotive systems, XL timing belts can be used in auxiliary drives, water pumps, and more, helping synchronize engine components.

xl timing belt

4. Manufacturing Timing belts are employed in conveyor systems and automated manufacturing processes to facilitate the movement of materials and products.

5. Home Appliances Various appliances, such as washing machines and food processors, utilize these belts for driving motors and ensuring operational efficiency.

Maintenance Tips

To ensure that XL timing belts perform optimally, regular maintenance is crucial. Here are some maintenance tips

1. Regular Inspection Periodically check the belt for signs of wear, such as fraying, cracking, or excessive stretching. Early detection of damage can prevent failures.

2. Alignment Ensure that the pulleys and the belt are properly aligned. Misalignment can lead to uneven wear and premature failure of the belt.

3. Tension Checking Proper tension is vital for the effective operation of timing belts. Too much tension can lead to belt damage, while too little can cause slipping. Use a tension gauge to check the belt tension at regular intervals.

4. Clean Environment Keep the area around the timing belt clean and free from debris. Particles can get lodged in the belt or pulleys, leading to damage over time.

5. Replacement Timing belts should be replaced according to the manufacturer’s recommendations or if any signs of significant wear are observed. Ignoring these signs can lead to costly failures.

Conclusion

XL timing belts are a versatile and essential component in many mechanical systems. Their specific design and reliable performance make them a popular choice across various industries. Understanding their specifications, applications, and maintenance practices can help users leverage their benefits effectively. By providing proper care and attention to XL timing belts, you can enhance the reliability and longevity of your machinery and equipment, ensuring smooth operation and optimal performance. Whether you are a hobbyist, an engineer, or run a manufacturing facility, knowing about XL timing belts will certainly prove advantageous.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025