- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

දෙසැ. . 01, 2024 01:27 Back to list

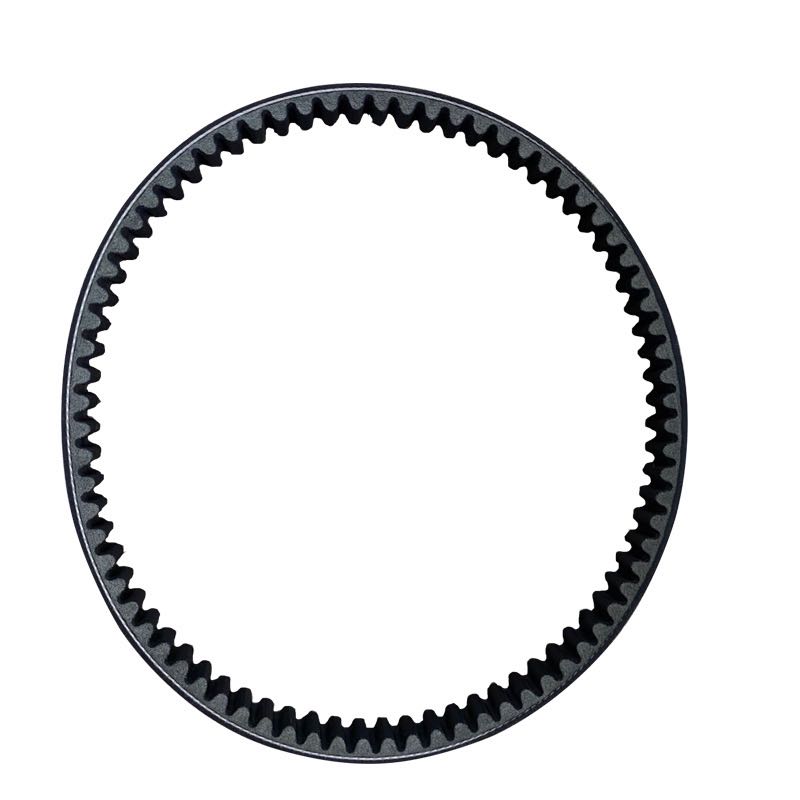

sprocket and toothed belt

Understanding Sprockets and Toothed Belts Key Components in Mechanical Systems

In the realm of mechanical engineering, the intricate dance between various components drives the functionality of machines and systems. Among these components, sprockets and toothed belts play a critical role, particularly in the context of power transmission. These elements are not only essential in machinery but also have applications in diverse fields ranging from automotive to industrial equipment.

Understanding Sprockets and Toothed Belts Key Components in Mechanical Systems

Toothed belts, on the other hand, are flexible components made from durable materials such as rubber or polyurethane, reinforced with fibers for added strength. The belt features teeth that mesh with the sprockets, allowing for a smooth and efficient power transfer. One of the significant advantages of using toothed belts is that they eliminate the need for lubrication, which is often required for chains. This characteristic not only simplifies maintenance but also enhances the operational lifespan of the system.

sprocket and toothed belt

The combination of sprockets and toothed belts creates a highly efficient drive system. For instance, in automotive applications, this pairing can be seen in timing belt systems, where the rotation of the crankshaft is synchronized with the camshaft to ensure that the engine operates smoothly and effectively. The precise timing of the belt and sprocket allows for optimal engine performance, reducing wear and tear on components and improving fuel efficiency.

Industrial applications also benefit greatly from sprocket and toothed belt systems. Conveyor systems, for example, often rely on these components for the movement of goods. The ability to handle different weight loads and speeds makes toothed belts preferable in many scenarios. Their flexibility and resilience allow them to adapt to various operational conditions, enabling industries to maintain high productivity levels.

Moreover, the design advancements in sprockets and toothed belts have led to innovations that further enhance their efficiency. The development of quieter materials and specialized tooth designs reduces noise and vibration, improving the overall user experience in both industrial and automotive contexts. Additionally, the use of computer-aided design (CAD) tools allows engineers to simulate and optimize the interactions between these components, leading to more effective designs that can withstand the rigors of daily use.

In conclusion, sprockets and toothed belts are indispensable components in modern mechanical systems. Their ability to provide efficient power transmission while requiring minimal maintenance makes them ideal for a wide range of applications. As technology advances, the performance and capabilities of these components will continue to evolve, ensuring that they remain at the forefront of engineering solutions. Whether in vehicles or industrial machinery, the partnership between sprockets and toothed belts will undoubtedly play a vital role in driving innovation and efficiency in the future.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025