- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

අගෝ. . 25, 2025 02:40 Back to list

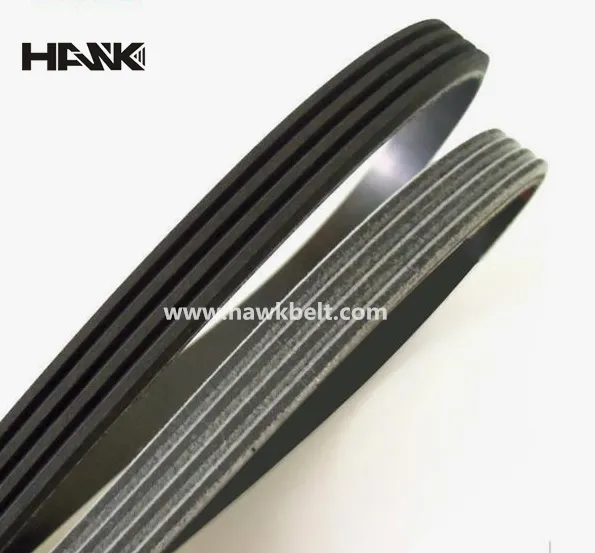

Precision Lathe Drive Belts: Durable & Reliable Performance

Introduction to High-Performance Drive Belts in Industrial Lathes

In the demanding landscape of modern manufacturing, precision and reliability are paramount. Central to the operational efficiency of countless industrial machines, particularly lathes, are high-quality power transmission components. Among these, lathe drive belts stand out as critical elements. These specialized belts are engineered to transmit power from a motor to the spindle, enabling the rotational motion essential for machining operations. Unlike generic power transmission solutions, belts designed for lathes must exhibit exceptional durability, dimensional stability, and resistance to environmental stressors inherent in machine shop environments. Their performance directly impacts the accuracy, finish, and overall productivity of machined parts, making their selection a strategic decision for any facility. This comprehensive guide delves into the intricate world of these essential components, exploring their technical facets, application versatility, and the crucial role they play in modern industrial processes.

The evolution of industrial machinery, including advanced CNC lathes, necessitates drive belts that can handle higher torques, faster speeds, and prolonged operational cycles without degradation. This has led to significant advancements in material science and manufacturing techniques for these components. Understanding the underlying technologies, from rubber compounds to reinforcement fibers, is key to appreciating their performance characteristics. This article aims to equip B2B decision-makers and engineers with the knowledge required to select, implement, and maintain optimal drive belt solutions, ensuring peak operational performance and longevity for their valuable machinery.

Current Industry Trends and Innovations in Drive Belt Technology

The landscape for industrial power transmission is continuously evolving, driven by demands for increased efficiency, reduced maintenance, and enhanced sustainability. For lathe drive belts, key trends include the development of advanced elastomer compounds for superior heat and abrasion resistance, alongside innovative reinforcement technologies. For instance, the use of high-modulus aramid cords or fiberglass tensile members is becoming standard, offering improved strength-to-weight ratios and reduced elongation, which translates to better dimensional stability and longer service life.

- Energy Efficiency: A significant push towards "green" manufacturing has spurred the development of low-friction lathe belt designs, such as synchronous belts with optimized tooth profiles, which minimize energy loss. Studies indicate that upgrading to high-efficiency belts can result in energy savings of 2-5% in continuous operation, contributing to lower operational costs and a reduced carbon footprint.

- Smart Sensing & IoT Integration: Emerging trends include the integration of sensors within drive belts or their immediate environment to monitor tension, temperature, and vibration in real-time. This predictive maintenance approach allows for early detection of wear or potential failure, drastically reducing unscheduled downtime.

- Material Science Advancements: Research into new synthetic rubbers and polyurethanes, offering enhanced resistance to chemicals, oils, and extreme temperatures, is expanding the application range of drive belts into more aggressive environments. This is crucial for sectors like petrochemicals where equipment is exposed to corrosive substances.

Furthermore, the principles applied to heavy-duty automotive applications, such as the design of a robust fan belt truck, are influencing industrial belt design, leading to more resilient and long-lasting solutions for demanding industrial machinery. The lessons learned from ensuring the reliability of a fan belt car or even the complex dynamics of the serpentine belt are increasingly being adapted to industrial contexts, emphasizing compact design and multi-rib functionality. These innovations collectively contribute to superior operational reliability and performance across various industrial sectors.

The Manufacturing Process of Lathe Drive Belts: From Raw Material to Precision Component

The creation of a high-performance lathe drive belt is a sophisticated multi-stage process, demanding rigorous material selection and precise engineering. It begins with the careful formulation of rubber compounds, which are the heart of the belt's flexibility, grip, and resistance to environmental factors.

1. Material Selection and Preparation

The primary materials include synthetic rubbers like EPDM (Ethylene Propylene Diene Monomer) or HNBR (Hydrogenated Nitrile Butadiene Rubber) for their excellent temperature resistance and longevity. Reinforcement cords, typically high-tensile polyester, aramid, or fiberglass, are selected for their strength and low stretch properties. The cover fabric, often a bias-cut cotton-polyester blend impregnated with rubber, provides wear resistance and protects the inner components.

2. Compounding and Extrusion

Raw rubber polymers are mixed with various additives (fillers, accelerators, antioxidants, vulcanizing agents) in Banbury mixers to achieve specific mechanical and chemical properties. This compounded rubber is then extruded into sheets or profiles that will form the core of the belt. The reinforcement cords are precisely laid into the rubber matrix.

3. Building and Vulcanization

The belt construction involves layering the extruded rubber, reinforcement cords, and cover fabric onto a drum or former. For V-belts, this creates the characteristic wedge shape; for multi-rib or serpentine belts, specialized molding techniques are used to form the ribs. The assembly is then placed into a vulcanizing press, where heat and pressure chemically cross-link the rubber polymers, giving the belt its permanent shape, elasticity, and strength. This is a critical step, akin to the precision required in CNC machining of metal parts, ensuring the belt's integrity and performance.

4. Finishing and Testing

After vulcanization, the continuous belt is cut to precise widths and lengths. Each batch undergoes rigorous quality control, adhering to international testing standards such as ISO 9001, DIN, and RMA (Rubber Manufacturers Association). Tests include dimensional accuracy, length stability under tension, flexibility, and resistance to oil, heat, and abrasion. For instance, testing for a 4PK belt like the Doosan Parts Drive Rubber Belt 2106-1019D10 involves dynamic fatigue tests to simulate real-world operating conditions, ensuring a service life that meets or exceeds industry expectations. These stringent standards guarantee that the final product, a lathe belt, delivers consistent, reliable performance in demanding industrial applications within target industries such as petrochemical, metallurgy, and water supply & drainage. The advantages in typical application scenarios include energy saving through optimized friction coefficients and superior corrosion resistance due to advanced material compounds.

Technical Specifications and Performance Parameters

Understanding the technical specifications of lathe drive belts is crucial for optimal selection and performance in industrial machinery. Key parameters dictate a belt's suitability for specific applications, influencing efficiency, durability, and operational costs.

Key Performance Indicators (KPIs):

- Length Stability: Measured as the minimal stretch under rated load, ensuring consistent speed ratios and preventing slippage. Advanced materials achieve length stability typically within 0.1% over their lifespan.

- Coefficient of Friction: A critical factor for power transmission. Modern belts aim for a high and stable coefficient of friction to maximize power transfer while minimizing heat generation.

- Temperature Resistance: Operating range is vital. High-performance belts are rated for continuous operation from -30°C to +100°C, with some specialized belts tolerating up to 120°C.

- Flex Fatigue Resistance: The ability of the belt to withstand repeated bending over pulleys without degradation of its internal structure. This is directly linked to the choice of cord material and rubber compound.

- Abrasion and Chemical Resistance: Essential for longevity in harsh industrial environments, protecting against dust, coolants, and oils.

For instance, the Doosan Parts Drive Rubber Belt 2106-1019D10, a 4PK belt, signifies a multi-rib (poly-V) belt with four ribs, designed for compact drives and high power transmission capacity. Such belts are engineered to provide superior flexibility and reduced heat build-up compared to traditional V-belts.

Product Specification Table: Doosan Parts Drive Rubber Belt 2106-1019D10

Application Scenarios and Target Industries

The versatility and reliability of industrial drive belts mean they are integral to a vast array of machines and sectors. While the term "lathe drive belts" specifically refers to their application in lathes for metalworking, woodworking, and other precision turning operations, the fundamental principles extend to many other critical industrial applications.

Typical Application Scenarios:

- CNC Lathes and Machining Centers: Ensuring precise, high-speed spindle rotation for intricate component manufacturing.

- Conventional Lathes: Transmitting power smoothly from motor to gearbox or spindle, often requiring robust V-belts.

- Grinding Machines: Providing consistent power for abrasive processes, where vibration damping is crucial.

- Pumps and Compressors: Found in water supply & drainage systems and petrochemical plants, where continuous operation and resistance to harsh environments are essential.

- Material Handling Equipment: Conveyors, elevators, and agitators in metallurgy and mining.

Target Industries:

- Metalworking & Automotive: High-precision machining of engine components, gears, and structural parts.

- Petrochemical: Driving pumps, mixers, and compressors in refineries and chemical processing plants, requiring excellent chemical and temperature resistance.

- Metallurgy & Mining: Robust power transmission for heavy-duty machinery, crushers, and conveyors, often in dusty and abrasive conditions.

- Water Supply & Drainage: Reliable operation of large pumps and filtration systems, often in wet or humid environments.

- Food & Beverage: Ensuring hygienic and reliable operation of processing and packaging machinery, often requiring FDA-compliant materials.

- Agriculture: Powering various farming machinery, from harvesting equipment to irrigation systems.

The demand for precise and efficient power transmission is universal across these sectors. The Doosan Parts Drive Rubber Belt, for example, is specifically tailored for Doosan equipment, commonly found in heavy industries, further emphasizing the need for robust and reliable lathe belt solutions.

Technical Advantages of Modern Lathe Drive Belts

Modern lathe drive belts offer a multitude of technical advantages that directly contribute to improved operational efficiency, reduced maintenance, and enhanced safety in industrial settings. These benefits stem from continuous innovation in material science, design, and manufacturing processes.

Energy Saving and Efficiency:

- Reduced Friction: Advanced rubber compounds and precision-ground surfaces minimize friction losses, leading to higher power transmission efficiency. High-efficiency belts can offer up to 98% efficiency, compared to 95% for older models.

- Optimized Profile: Multi-rib (PK series) and synchronous belt profiles are designed for optimal engagement with pulleys, reducing slippage and wasted energy.

- Lower Heat Generation: More efficient power transfer means less energy is converted into heat, extending belt life and reducing stress on other drive components.

Corrosion Resistance and Durability:

- Chemical & Oil Resistance: Specialized elastomers like HNBR and EPDM provide superior resistance to industrial oils, coolants, and various chemicals, preventing material degradation and premature failure.

- Temperature Extremes: Belts are engineered to perform reliably across broad temperature ranges, from freezing conditions to high-heat operational environments (e.g., -40°C to +120°C).

- Abrasive Environment Protection: Robust outer fabrics and compounds withstand dust, grit, and other abrasive particles common in manufacturing plants.

Enhanced Precision and Reduced Vibration:

- Minimal Stretch: High-tensile reinforcement cords ensure minimal elongation under load, maintaining consistent speed ratios crucial for precision machining.

- Vibration Damping: The elastic properties of the rubber absorb shock loads and dampen vibrations, reducing noise levels and protecting bearings and other machine components from wear.

- Quiet Operation: Precision manufacturing and optimized profiles lead to smoother operation, reducing noise levels in the workshop, contributing to a better working environment.

These technical advantages translate directly into higher productivity, lower operational expenditures, and extended machinery lifespan, making the choice of advanced lathe belt technology a strategic investment.

Vendor Comparison: Selecting the Right Partner for Drive Belt Solutions

Choosing the right vendor for lathe drive belts is as critical as selecting the belt itself. A reliable supplier offers not only high-quality products but also technical expertise, customization capabilities, and dependable after-sales support. This comparison focuses on factors essential for B2B procurement.

Key Comparison Factors:

- Product Quality & Certifications: Adherence to ISO 9001, DIN, RMA, and other industry-specific certifications (e.g., for specific machinery OEMs).

- Material Expertise: Depth of knowledge in elastomer compounds, reinforcement fibers, and their application to specific operational conditions.

- Customization Capabilities: Ability to provide non-standard sizes, specialized materials, or unique profiles for bespoke machinery.

- Technical Support: Availability of engineering assistance for drive design, troubleshooting, and optimization.

- Lead Time & Logistics: Efficiency in order processing, manufacturing, and global distribution.

- Warranty & After-Sales Service: Clear warranty policies and responsive support for any product-related issues.

Vendor Comparison Table (Illustrative):

For specialized applications, such as the Doosan Parts Drive Rubber Belt 2106-1019D10, working with a vendor like HAWKBelt that understands OEM specifications and can supply exact-fit replacements or superior alternatives is paramount. This ensures seamless integration and sustained machine performance, mitigating the risks associated with incompatible or substandard parts.

Customized Solutions for Unique Industrial Demands

While standard lathe drive belts meet the needs of many applications, certain industrial scenarios demand bespoke solutions. Customization allows for optimal performance in unique operating environments, specialized machinery, or highly specific power transmission requirements that off-the-shelf products cannot address.

Areas of Customization:

- Material Composition: Tailoring rubber compounds for enhanced resistance to specific chemicals (e.g., strong acids, alkalis), extreme temperatures (cryogenic or ultra-high heat), or specialized conductive/antistatic properties.

- Reinforcement Cords: Utilizing aramid, carbon fiber, or specialized steel cords for applications requiring exceptionally high tensile strength, minimal elongation, or increased shock load capacity.

- Belt Profiles & Dimensions: Creating unique rib patterns, tooth profiles, or non-standard lengths and widths to fit proprietary machinery designs or optimize contact area for specific pulley geometries.

- Surface Treatments: Applying specialized coatings for enhanced grip, reduced noise, or improved wear resistance in highly abrasive conditions.

- Integrated Features: Incorporating features like perforations for cooling, or even embedded sensors for real-time performance monitoring in advanced IoT-enabled systems.

A key partner for customization should possess robust R&D capabilities, extensive material science knowledge, and flexible manufacturing processes. This collaborative approach ensures that the customized belt not only fits perfectly but also performs optimally, often leading to significant improvements in machine uptime, efficiency, and overall operational longevity. For example, a specialized lathe belt for high-speed diamond turning machines might require extreme precision in length stability and dynamic balance, necessitating a custom-engineered solution beyond standard offerings.

Application Case Studies: Real-World Performance and Customer Success

Demonstrating the tangible benefits of high-quality lathe drive belts through real-world applications provides invaluable insight for B2B decision-makers. These case studies highlight how superior belt technology addresses critical operational challenges and delivers measurable improvements.

Case Study 1: Enhanced Productivity in Automotive Component Manufacturing

- Client: Large automotive parts manufacturer specializing in engine blocks.

- Challenge: Frequent belt slippage and premature wear on CNC lathes operating 24/7, leading to inconsistent part quality and unscheduled downtime every 3-4 months. The existing lathe belt solution (standard V-belts) was not coping with the high torque and dynamic loads.

- Solution: Replaced traditional V-belts with the Doosan Parts Drive Rubber Belt 2106-1019D10 4PK (a multi-rib EPDM belt with advanced cord technology). This multi-rib design provided greater surface contact and superior flexibility.

- Results:

- Belt Service Life Increased: From 3-4 months to over 18 months, reducing replacement costs and maintenance labor by 80%.

- Downtime Reduction: Eliminated unscheduled downtime related to belt failure.

- Improved Part Quality: Consistent power transmission led to fewer defects and higher precision in machined components.

- Noise Reduction: Operators reported a noticeable decrease in machine noise, improving the working environment.

Case Study 2: Corrosion Resistance in a Chemical Processing Plant

- Client: Specialty chemical manufacturer using lathes for precision component fabrication in a corrosive environment.

- Challenge: Exposure to airborne chemical vapors (dilute acids, solvents) caused rapid degradation of standard rubber belts (fan belt car equivalent materials), leading to embrittlement and cracking within six months.

- Solution: Implemented custom-designed lathe drive belts utilizing an HNBR (Hydrogenated Nitrile Butadiene Rubber) compound, specifically engineered for superior chemical and heat resistance, combined with aramid fiber reinforcement.

- Results:

- Extended Service Life: Belt lifespan increased to over 2 years, a 400% improvement.

- Reduced Maintenance: Significantly lowered the frequency of belt inspections and replacements.

- Enhanced Safety: Minimized the risk of sudden belt failures in a hazardous environment.

Trustworthiness: FAQ, Lead Time, Warranty, and Support

Building trust with B2B clients requires transparency and robust support systems. Our commitment to quality extends beyond product manufacturing to encompass every aspect of the customer journey, from initial inquiry to long-term operational support.

Frequently Asked Questions (FAQ):

- Q: How do I select the correct size for my lathe?

- A: Accurate measurement of the existing belt (length, width, number of ribs) and checking the machine's OEM specifications are crucial. Our technical team can assist with cross-referencing and recommendations based on your machinery model, like the Doosan Parts Drive Rubber Belt 2106-1019D10, or required power transmission.

- Q: What is the typical service life of your lathe drive belts?

- A: While actual life varies based on application severity, environment, and maintenance, our belts are engineered for a service life of 5,000 to 10,000 operating hours under ideal conditions, thanks to superior materials and manufacturing processes.

- Q: Are your belts compatible with older machinery?

- A: Yes, we offer a wide range of standard and custom sizes suitable for both legacy and modern industrial equipment. Our engineers can provide guidance on upgrading older drive systems for improved efficiency.

- Q: What makes your belts superior to standard automotive belts (e.g., the serpentine belt) for industrial use?

- A: While some material similarities exist, industrial lathe belts are designed for continuous, high-load operation, often in more extreme temperatures and chemical exposures, with strict requirements for dimensional stability and precision that exceed typical automotive applications. They are built for endurance, not just intermittent use.

Lead Time and Fulfillment:

We maintain a robust inventory of popular lathe belt types and sizes, including the Doosan 2106-1019D10 4PK. Standard orders typically ship within 3-7 business days. For customized solutions or large volume orders, lead times will be provided upon consultation and design approval, ranging from 2-4 weeks. We leverage efficient global logistics networks to ensure timely delivery to your operational sites.

Warranty Commitments:

All our industrial drive belts come with a standard 12-month limited warranty against manufacturing defects from the date of purchase. Extended warranty options may be available for specific product lines or large-scale project installations. Our commitment is to provide products that meet or exceed industry standards, ensuring peace of mind for our customers.

Customer Support:

Our dedicated customer support team and engineering specialists are available to assist with product selection, technical inquiries, installation guidance, and troubleshooting. We offer multi-channel support via phone, email, and a comprehensive online resource center, ensuring prompt and expert assistance whenever needed. Our goal is to forge lasting partnerships by providing unparalleled service and reliable solutions.

Conclusion

The performance of lathe drive belts is a critical determinant of operational efficiency, precision, and longevity in industrial machinery. As manufacturing processes become more demanding, the evolution of drive belt technology continues to deliver advanced solutions that offer superior energy efficiency, enhanced durability, and greater resistance to harsh operating conditions. By understanding the intricate manufacturing processes, technical specifications, and application advantages, B2B decision-makers and engineers can make informed choices that optimize their power transmission systems. Partnering with a reputable vendor committed to quality, customization, and robust after-sales support ensures not only the supply of high-performance components like the Doosan Parts Drive Rubber Belt 2106-1019D10 but also access to the expertise required to maximize their value. Investing in advanced drive belt technology is an investment in the long-term reliability and productivity of industrial operations.

References

- International Organization for Standardization (ISO). (Current Year). ISO 9001: Quality management systems – Requirements.

- Rubber Manufacturers Association (RMA). (Current Year). RMA IP-20: Specifications for Drives Using Classical V-Belts.

- Gates Corporation. (Latest Publication). Gates Industrial Belts Product Catalog & Technical Manual.

- Dayco Products LLC. (Latest Publication). Dayco Industrial Product Catalog & Engineering Guide.

- Society of Automotive Engineers (SAE). (Current Year). SAE J637: Automotive V-Belt and Pulley System Design.

This is the last article

-

Precision Lathe Drive Belts: Durable & Reliable Performance

NewsAug.25,2025

-

84.5 Serpentine Belt: Durable & Precision Fit for Your Engine

NewsAug.24,2025

-

Premium Ribbed Drive Belts for Quiet Power Transmission

NewsAug.23,2025

-

High-Performance Vehicle Timing Belt for Engine Precision

NewsAug.22,2025

-

Adjustable Drive Belts: Custom Fit & Easy Installation

NewsAug.21,2025

-

Precision Rubber Belt with Teeth | Timing & Variable Speed Belts

NewsAug.19,2025