- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Фев . 16, 2025 03:44 Back to list

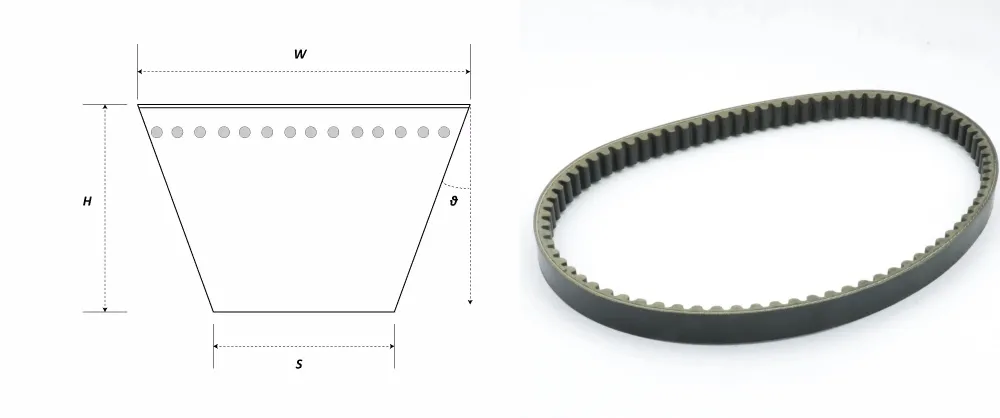

lathe drive belts

Lathe drive belts play a crucial role in the functionality of a lathe machine, acting as the intermediary that transfers power from the motor to the spindle. Selecting the right belt involves understanding various considerations to ensure optimal performance and longevity of the lathe.

A profound understanding of your operational needs can guide the selection of lathe drive belts. For instance, in high-speed applications, a belt with less mass and higher tensile strength is preferred to effectively manage the dynamic forces without compromising stability. Conversely, in high-torque operations, belts with a reinforced core can provide the necessary power transmission without stretching or breaking under load. From an expertise standpoint, consulting with belt manufacturers or suppliers can provide insights into the latest advancements in belt technology. Some manufacturers offer custom-made belts tailored to specific industrial requirements. Leveraging their expertise can lead to innovations that improve lathe performance, efficiency, and durability. Trustworthiness in selecting and maintaining lathe drive belts involves relying on vetted suppliers who provide guarantees and comply with industrial standards. High-quality belts typically come with certifications or warranties, providing added assurance of their longevity and performance capabilities. Additionally, establishing a relationship with a reliable supplier ensures continuous availability of replacement belts, mitigating the risk of downtime due to unavailable parts. Finally, integrating technological advancements, such as real-time monitoring of belt condition using IoT (Internet of Things) solutions, can revolutionize maintenance practices. These systems can detect anomalies in belt operation and prompt preventive maintenance before issues escalate, ultimately saving costs and increasing machine uptime. In conclusion, the optimal selection and maintenance of lathe drive belts is underpinned by a deep understanding of technical specifications, material insights, installation practices, and regular maintenance. Coupled with advancements in technology and robust supplier relationships, these practices can achieve superior performance and reliability in lathe operations.

A profound understanding of your operational needs can guide the selection of lathe drive belts. For instance, in high-speed applications, a belt with less mass and higher tensile strength is preferred to effectively manage the dynamic forces without compromising stability. Conversely, in high-torque operations, belts with a reinforced core can provide the necessary power transmission without stretching or breaking under load. From an expertise standpoint, consulting with belt manufacturers or suppliers can provide insights into the latest advancements in belt technology. Some manufacturers offer custom-made belts tailored to specific industrial requirements. Leveraging their expertise can lead to innovations that improve lathe performance, efficiency, and durability. Trustworthiness in selecting and maintaining lathe drive belts involves relying on vetted suppliers who provide guarantees and comply with industrial standards. High-quality belts typically come with certifications or warranties, providing added assurance of their longevity and performance capabilities. Additionally, establishing a relationship with a reliable supplier ensures continuous availability of replacement belts, mitigating the risk of downtime due to unavailable parts. Finally, integrating technological advancements, such as real-time monitoring of belt condition using IoT (Internet of Things) solutions, can revolutionize maintenance practices. These systems can detect anomalies in belt operation and prompt preventive maintenance before issues escalate, ultimately saving costs and increasing machine uptime. In conclusion, the optimal selection and maintenance of lathe drive belts is underpinned by a deep understanding of technical specifications, material insights, installation practices, and regular maintenance. Coupled with advancements in technology and robust supplier relationships, these practices can achieve superior performance and reliability in lathe operations.

Share:

Next:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025