- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Ноя . 09, 2024 03:52 Back to list

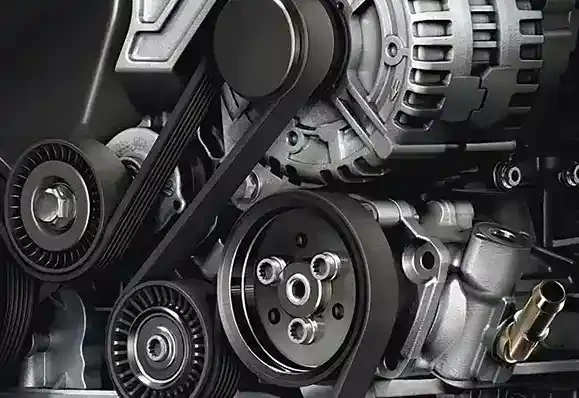

Understanding Belt Drive Systems for Efficient Power Transmission and Mechanical Movement

Understanding Belt Drives An Essential Mechanism in Mechanical Engineering

Belt drives are widely recognized as one of the most efficient means of transmitting mechanical power in various engineering applications. These systems consist of flexible belts that connect two or more rotating shafts, allowing them to transfer power and motion with minimal friction and wear. While belt drives are straightforward in design, they offer significant advantages in terms of efficiency, versatility, and maintenance.

Structure and Components

A typical belt drive system comprises a few key components belts, pulleys, and sometimes tensioning devices. The belts are made from materials such as rubber, leather, or synthetic composites, designed to handle varying loads and environmental conditions. Pulleys, usually made from metal or durable plastics, provide the surface for the belt to grip while facilitating rotational movement.

The configuration of a belt drive can be of several types, including open drives, crossed drives, and variable speed drives. An open belt drive features pulleys that rotate in the same direction, while a crossed belt drive has pulleys rotating in opposite directions—offering different torque and speed characteristics. Variable speed belt drives allow for adjustments in the belt tension and configuration, accommodating varying operational requirements.

Advantages of Belt Drives

One of the most significant benefits of belt drives is their efficiency. These systems can transmit high power levels with minimal energy loss due to low friction between the belt and the pulleys. This makes them especially suitable for applications requiring smooth acceleration and deceleration, such as in manufacturing processes or conveyor systems.

Moreover, belt drives are inherently flexible in terms of design and setup. They can easily accommodate dynamic assembly lines or machinery where spatial constraints may limit the option of direct shaft-to-shaft connections. The ability to position pulleys at various distances also contributes to the versatility of belt drives in various industrial applications.

Another important advantage is the relatively low maintenance requirement. Unlike gear systems, which may require frequent lubrication or adjustments, belt drives typically require only routine inspections and occasional tension adjustments to ensure optimal performance. This can lead to lower operational costs over the lifespan of the equipment, making belt drives more appealing to many industries.

belt drive

Applications

Belt drives find extensive applications across diverse industries. In the automotive sector, belt drives are used for fan drives, camshaft drives, and accessory drives, enabling efficient engine performance. In industrial settings, they are utilized in conveyor systems to transport materials across different stages of production. The simplicity of belt drives makes them also common in home appliances, such as washing machines and vacuum cleaners, where they assist in driving motors.

In addition, the ongoing advancements in materials technology have led to the development of high-performance belts that can withstand extreme conditions, including high temperatures and corrosive environments. This enhances the applicability of belt drives in sectors such as aerospace, renewable energy, and heavy manufacturing.

Challenges and Considerations

Despite their many benefits, belt drives do come with certain limitations that must be considered. One primary challenge is slip, which can occur if the belt stretches or if excessive load is applied. This can lead to a loss of power transmission and may require adjustments or replacements. Additionally, belts are susceptible to wear and fatigue over time, necessitating periodic inspections and replacements to maintain peak performance.

Environmental factors such as temperature, humidity, and exposure to chemicals can also affect the lifespan and efficiency of belt drives. Therefore, proper selection of materials and protective measures is vital to ensure longevity and reliability.

Conclusion

In summary, belt drives are an integral component of modern mechanical systems, offering an efficient, versatile, and low-maintenance solution for power transmission. Understanding the underlying principles, advantages, and potential challenges associated with belt drives is essential for engineers and designers seeking to optimize mechanical systems. As technology continues to evolve, the applications and capabilities of belt drives are likely to expand, reinforcing their importance in the ever-changing landscape of engineering and manufacturing.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025