- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ian. . 10, 2025 09:19 Back to list

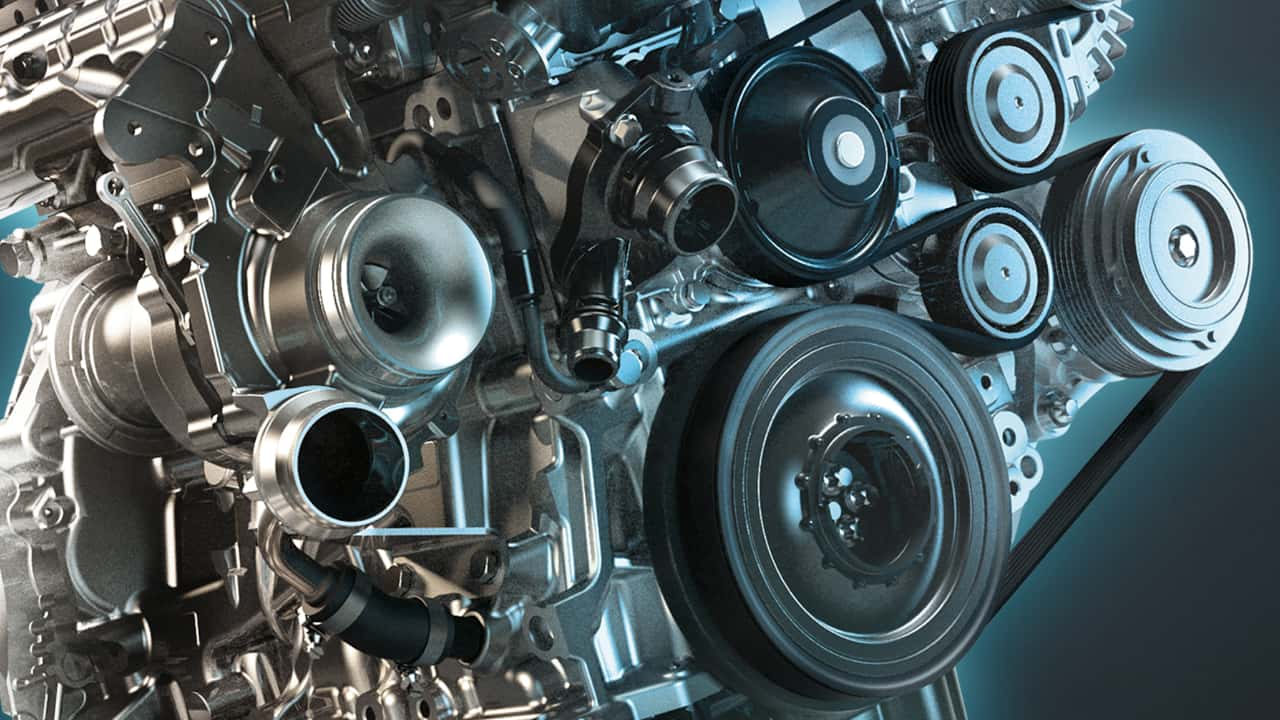

Auto Belt For Toyota/Hyundai/Kia

Selecting the right lathe drive belts can dramatically influence the precision, longevity, and efficiency of your lathe operations. Drive belts are the unsung heroes of lathes, transferring power from the motor to the spindle and enabling seamless machine operation. Understanding the nuances of these belts and selecting the right one can elevate not just your machine's performance but also your production quality.

Authoritative sources emphasize the importance of belt tension and alignment in maximizing belt performance. Misalignment and improper tension are common mishaps that degrade belt efficiency and lifespan. Proper installation and regular maintenance checks are recommended to ensure optimal belt tension. Tools such as tension testers and alignment gauges are indispensable in achieving this delicate balance. Ensuring the belt is not too tight prevents undue stress on the motor, while a belt that's too slack can lead to slipping, thereby affecting precision. The significance of drive belts in the broader scope of lathe machinery cannot be overstated. As machine operators seek to boost productivity, investing in high-quality belts becomes a prudent decision. Trustworthy manufacturers often offer belts with warranties and detailed specifications, helping users make informed decisions about compatibility and performance metrics. Testing reports and customer testimonials can serve as reliable indicators of a belt's credibility and its suitability for specific lathes. In conclusion, selecting the right lathe drive belt is an amalgamation of practical insights, expert recommendations, and authoritative guidance. For anyone serious about advancing their lathe operations, understanding the intricacies of drive belts is not just an option; it is a necessity. Prioritizing quality and applicability over mere cost consideration ensures that lathes perform optimally, sustain less downtime, and ultimately, deliver superior finished products.

Authoritative sources emphasize the importance of belt tension and alignment in maximizing belt performance. Misalignment and improper tension are common mishaps that degrade belt efficiency and lifespan. Proper installation and regular maintenance checks are recommended to ensure optimal belt tension. Tools such as tension testers and alignment gauges are indispensable in achieving this delicate balance. Ensuring the belt is not too tight prevents undue stress on the motor, while a belt that's too slack can lead to slipping, thereby affecting precision. The significance of drive belts in the broader scope of lathe machinery cannot be overstated. As machine operators seek to boost productivity, investing in high-quality belts becomes a prudent decision. Trustworthy manufacturers often offer belts with warranties and detailed specifications, helping users make informed decisions about compatibility and performance metrics. Testing reports and customer testimonials can serve as reliable indicators of a belt's credibility and its suitability for specific lathes. In conclusion, selecting the right lathe drive belt is an amalgamation of practical insights, expert recommendations, and authoritative guidance. For anyone serious about advancing their lathe operations, understanding the intricacies of drive belts is not just an option; it is a necessity. Prioritizing quality and applicability over mere cost consideration ensures that lathes perform optimally, sustain less downtime, and ultimately, deliver superior finished products.

Share:

Latest news

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025