- Arabic

- French

- Russian

- Spanish

- Portuguese

- Turkish

- Armenian

- English

- Albanian

- Amharic

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- Afrikaans

- Esperanto

- Estonian

- Finnish

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Punjabi

- Romanian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Set . 25, 2024 06:04 Back to list

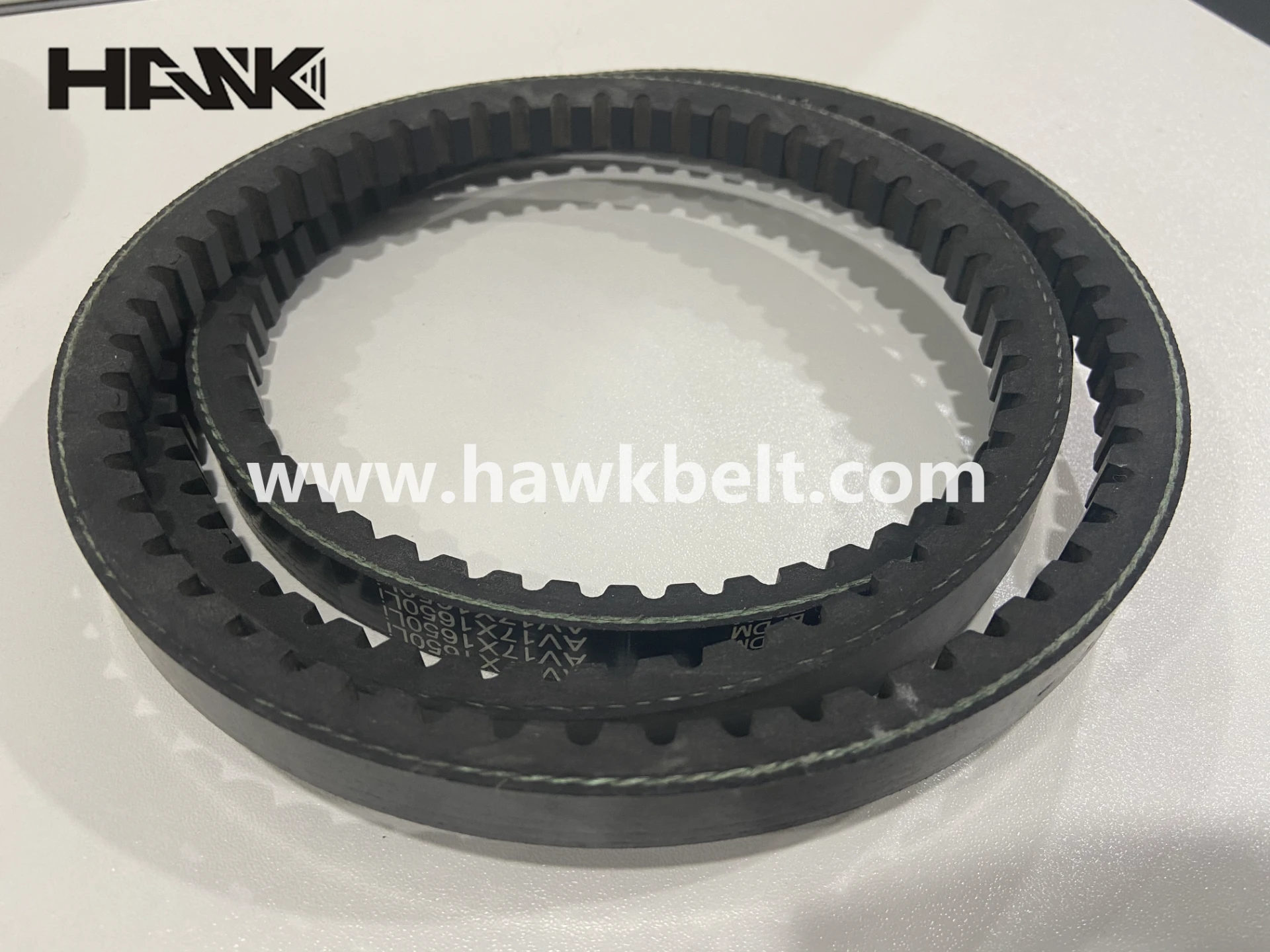

Understanding Variable Speed in Belt and Pulley Systems for Improved Performance and Efficiency

Understanding Variable Speed in Belt Pulley Systems

Variable speed belt pulley systems have become increasingly significant in various industries, offering flexibility and efficiency in power transmission. A belt pulley system consists of a series of pulleys connected by a belt, allowing for the transfer of rotational motion from one shaft to another. The ability to adjust the speed of these systems has profound implications for machinery performance, energy consumption, and operational control.

Understanding Variable Speed in Belt Pulley Systems

One commonly used method for variable speed adjustment involves the use of belt pulleys with varying diameters. By changing the pulley sizes, the speed of the belt and, consequently, the output shaft can be increased or decreased. Larger pulleys on the driving end will reduce speed at the driving end transmissive to smaller pulleys on the driven end, offering a simple yet effective means of speed control.

variable speed v belt pulley

Another increasingly popular method is the incorporation of electronic controls in conjunction with mechanical systems. These sophisticated setups allow for real-time adjustments and monitoring of speed, enhancing efficiency and performance even further. For instance, in a manufacturing assembly line, machinery can automatically adjust speeds to match the production rate or respond to changes in material flow, significantly improving productivity and reducing downtime.

The advantages of variable speed belt pulley systems extend beyond just operational efficiency. They contribute to lower energy consumption, which is critical in today's market focused on sustainability. By optimizing motor speeds based on demand, businesses can reduce energy usage and costs while also decreasing their environmental footprint.

In conclusion, variable speed in belt pulley systems is a crucial factor in modern industrial applications. As technology continues to evolve, these systems promise increased versatility, efficiency, and sustainability. Whether through mechanical means or advanced electronic control systems, the future of power transmission is leaning toward smarter, more adaptable solutions that can meet the dynamic demands of various industries. By embracing these advancements, businesses can ensure they remain competitive and responsive to the challenges of the ever-changing landscape of global markets.

-

Korean Auto Parts Timing Belt 24312-37500 For Hyundai/Kia

NewsMar.07,2025

-

7PK2300 90916-T2024 RIBBED BELT POLY V BELT PK BELT

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

Chinese Auto Belt Factory 310-2M-22 For BMW/Mercedes-Benz

NewsMar.07,2025

-

90916-02660 PK Belt 6PK1680 For Toyota

NewsMar.07,2025

-

drive belt serpentine belt

NewsMar.07,2025